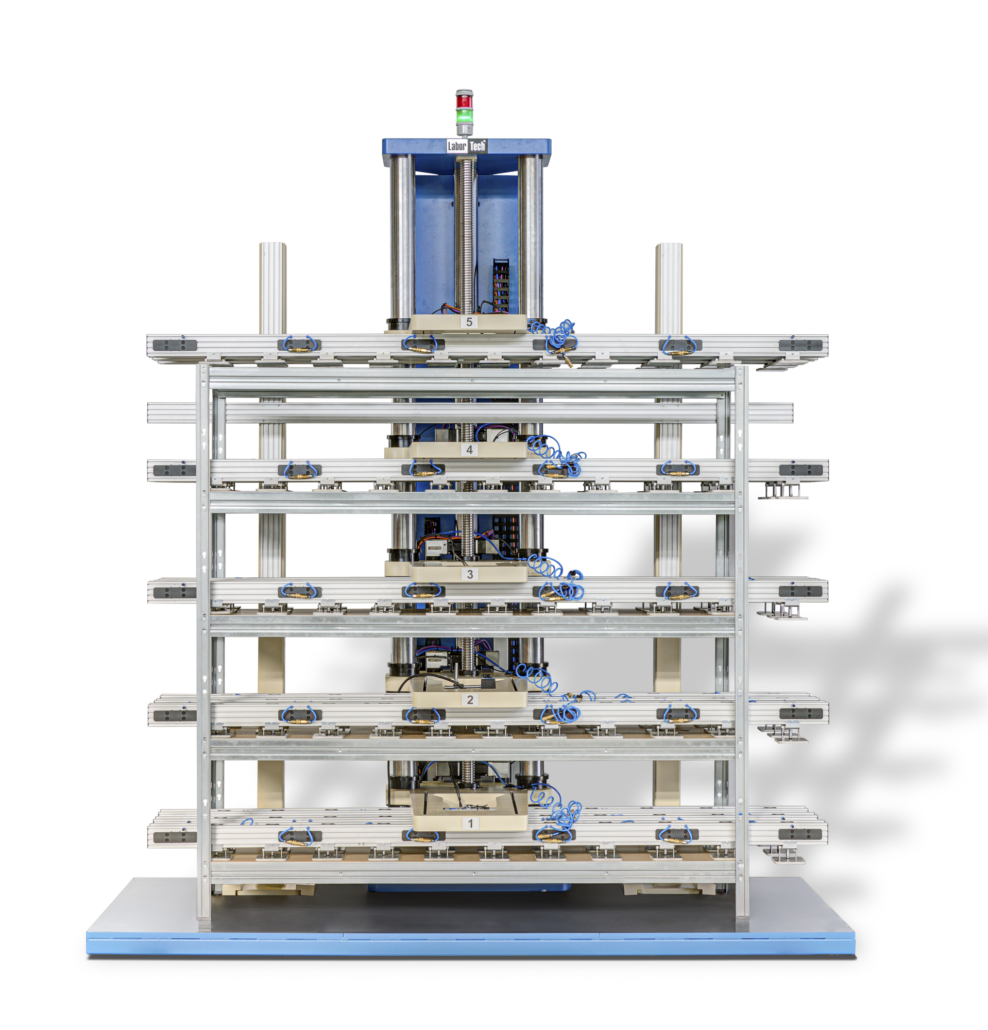

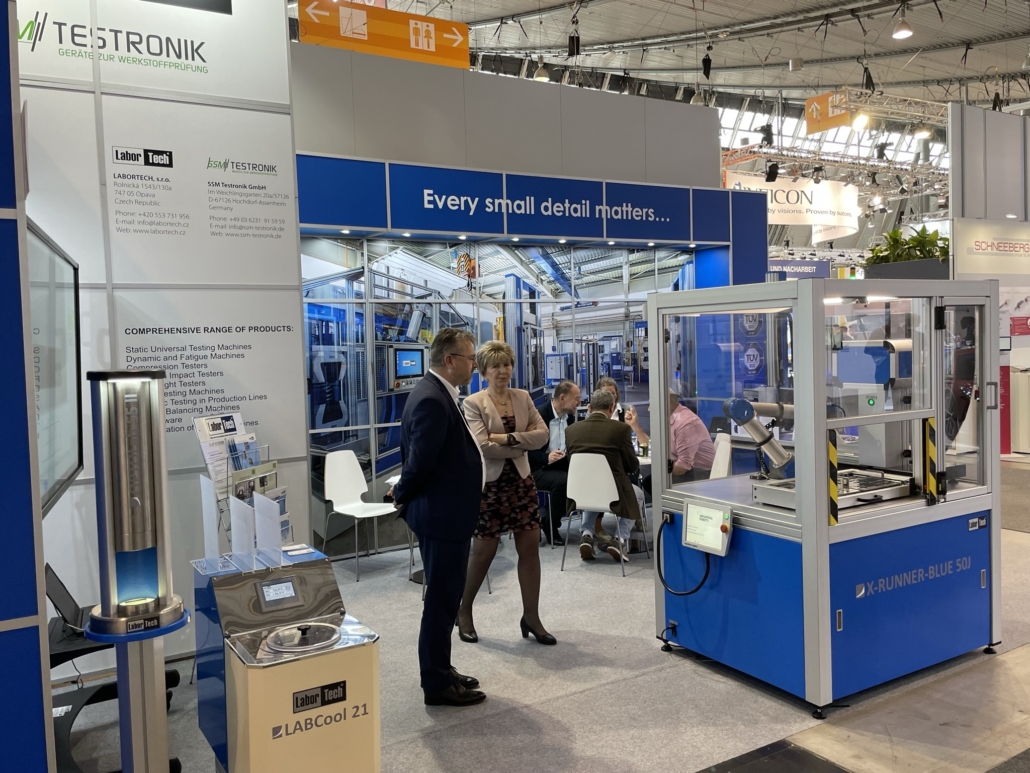

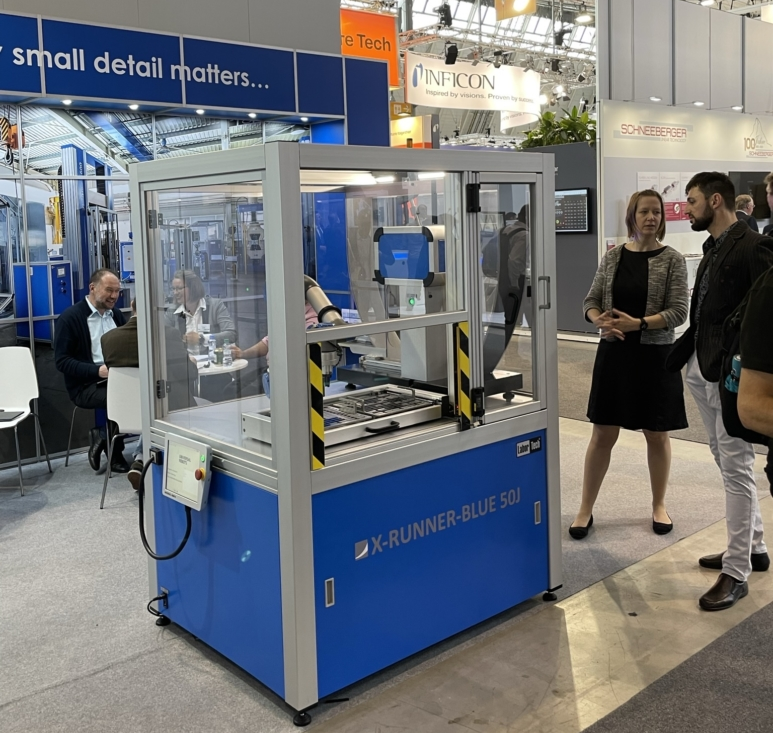

We are honored to announce that company LABORTECH, s.r.o. has entered into a new business agreement on exclusive representation with the Austrian company GGW Gruber & Co. GmbH..

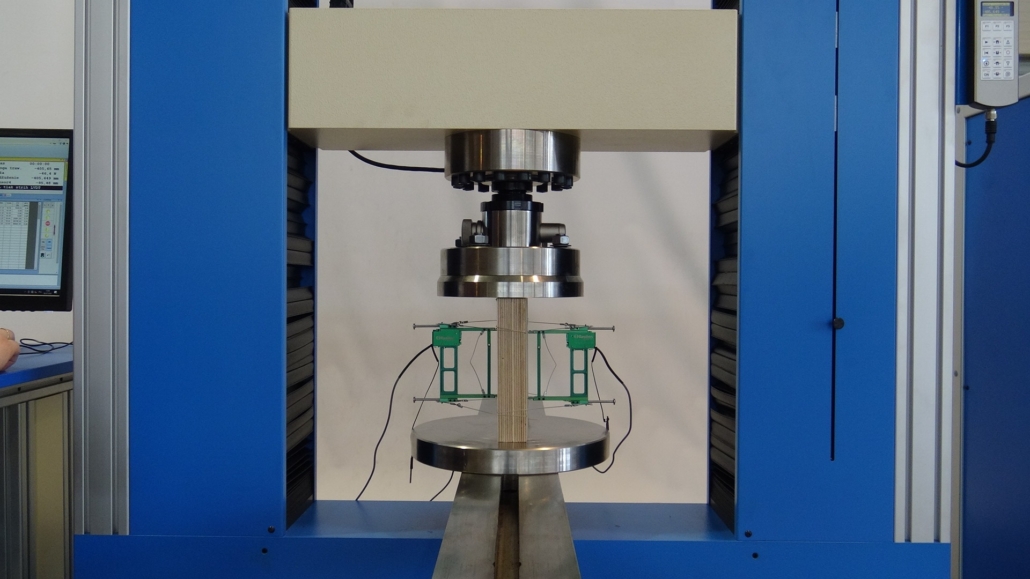

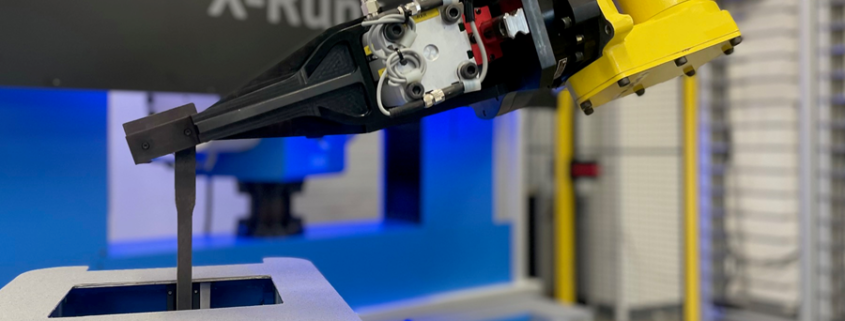

Our companies share the same values and corporate strategy, and the merger with this new partner opens up further opportunities for the sale of LABORTECH testing machines and equipment, including the implementation of projects in the field of mechanical testing of materials in Austria, Hungary and Serbia.

GGW Gruber innovation and technology since 1946

For more than seventy years, GGW Gruber has been part of the metal and plastics processing industry. It is also known as a competent and reliable collaborator for all things dimensional metrology. GGW’s products and services are subject to exacting criteria of continuous quality assurance and audits. These in-house requirements make GGW Gruber the ideal partner for LABORTECH as well as for businesses and companies with a heightened sense of quality and detail.

Partnering with the renowned company GGW Gruber is a huge opportunity for our company to develop and grow. In-depth cooperation and mutual understanding are key to a successful and long-term partnership.

TEAM LABORTECH