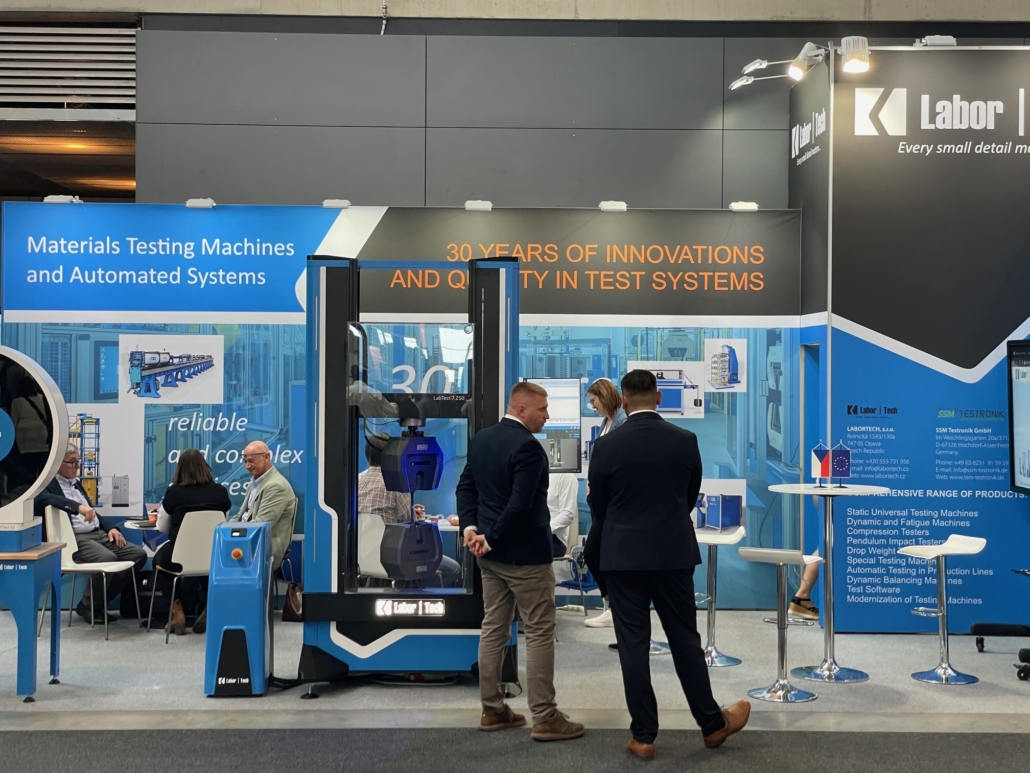

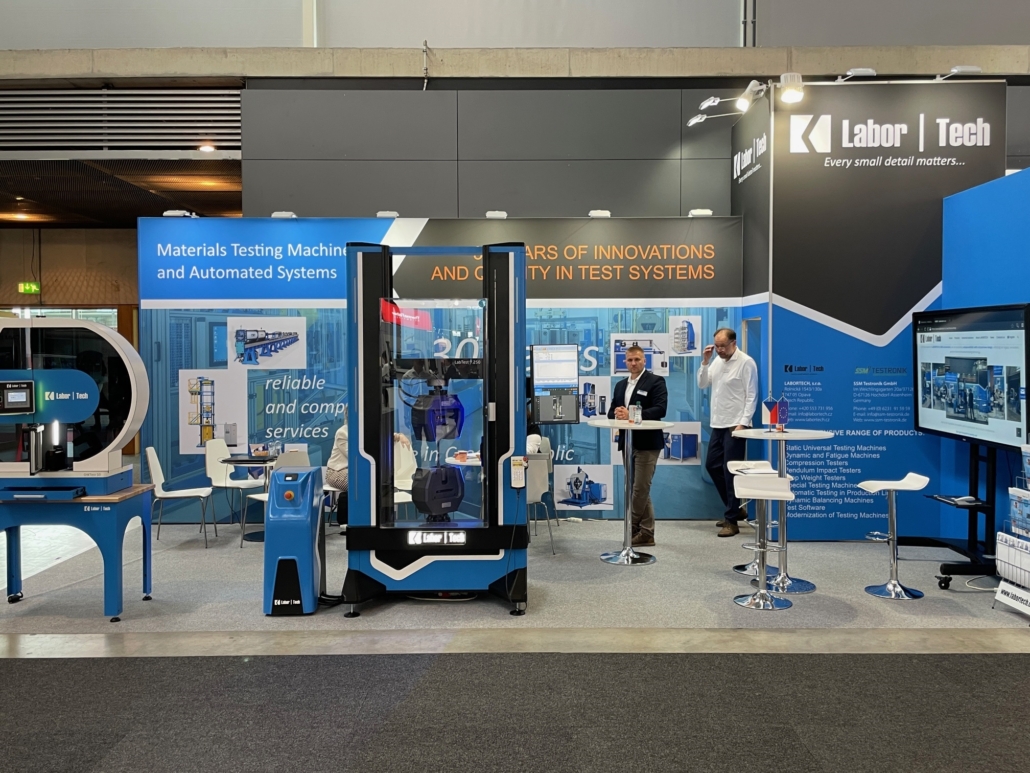

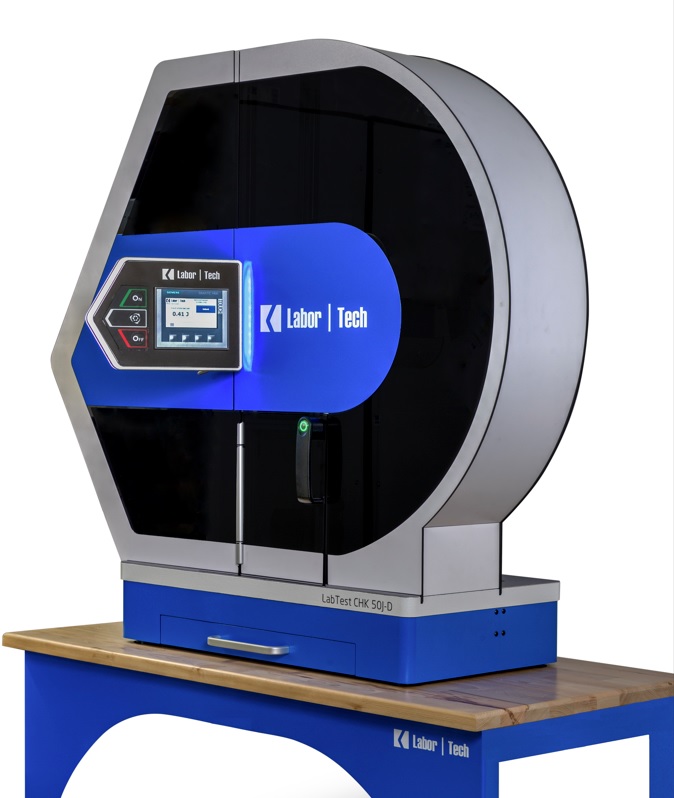

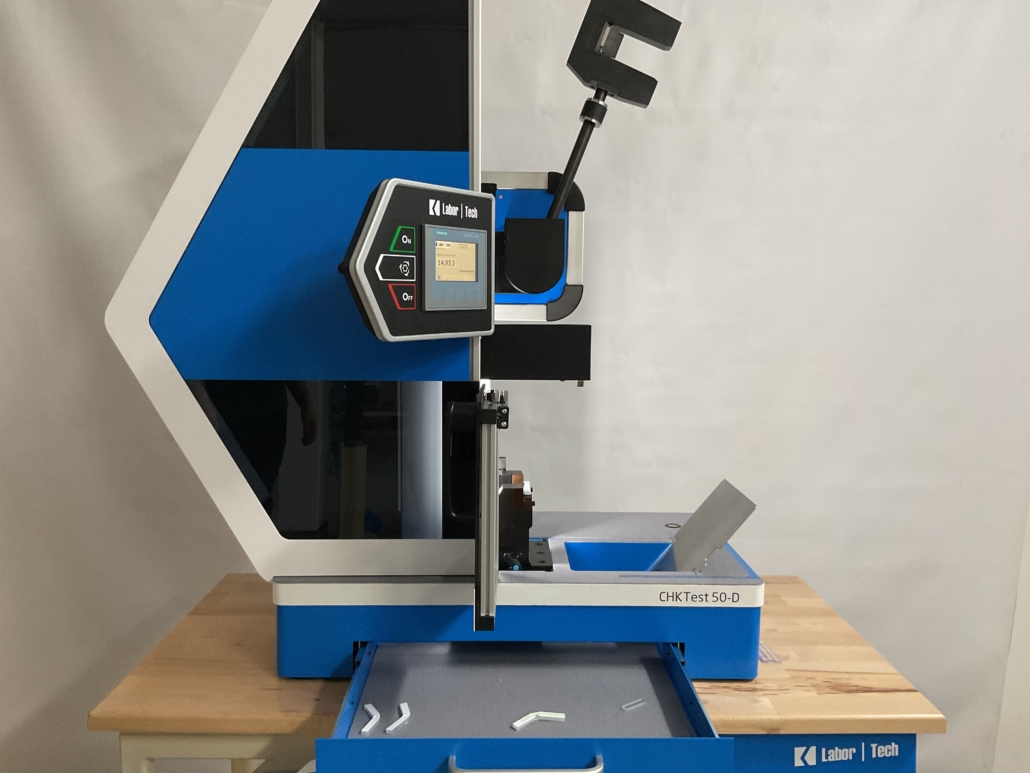

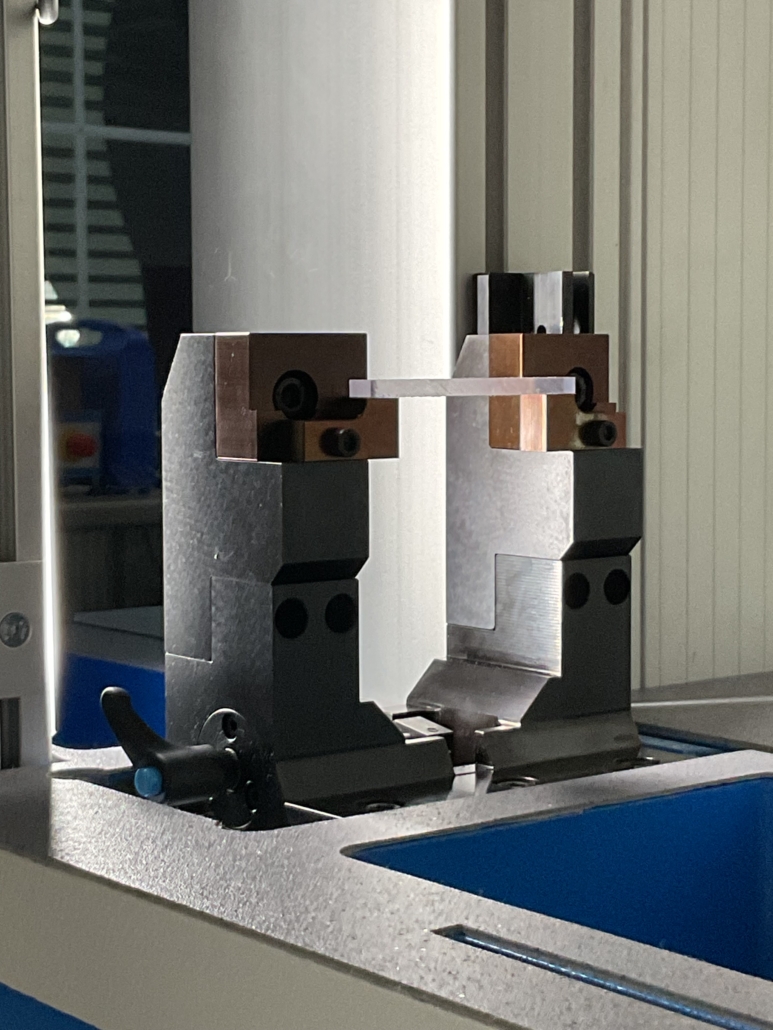

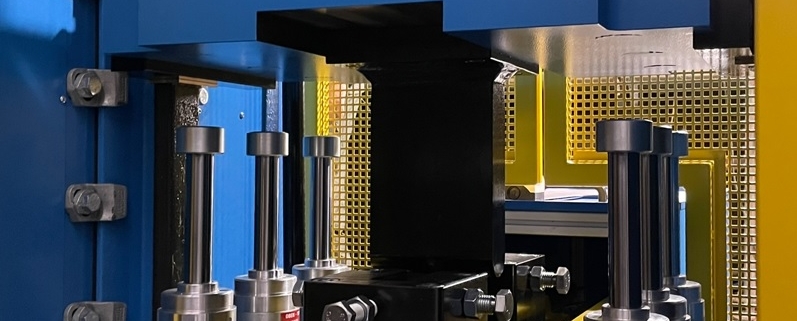

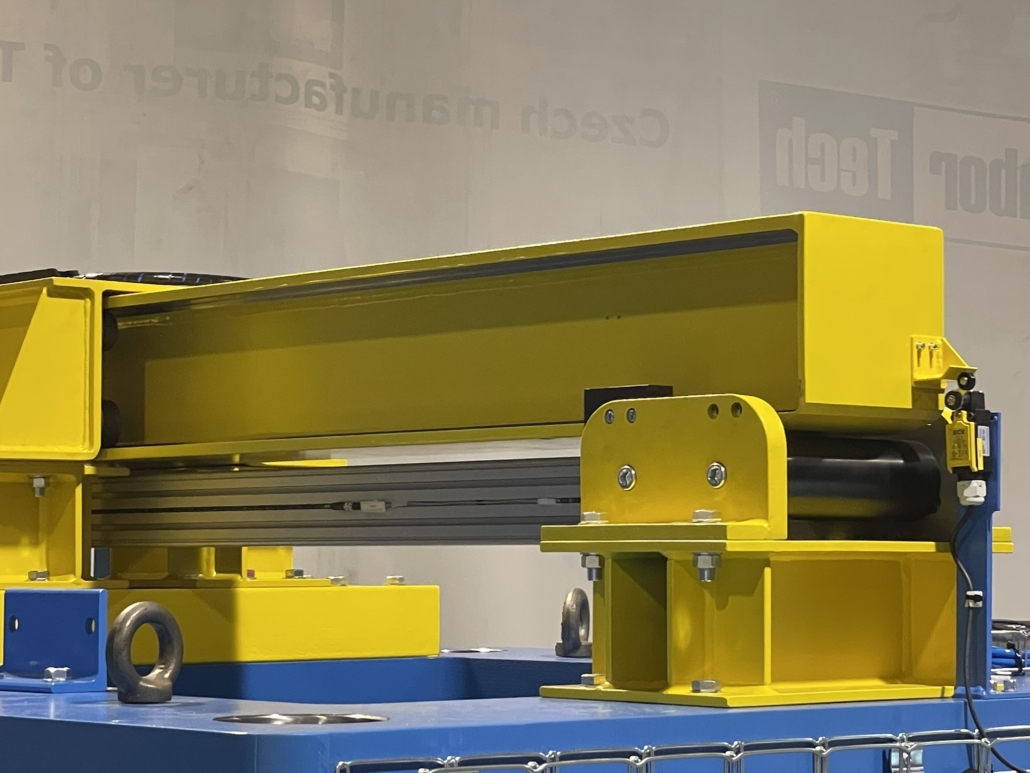

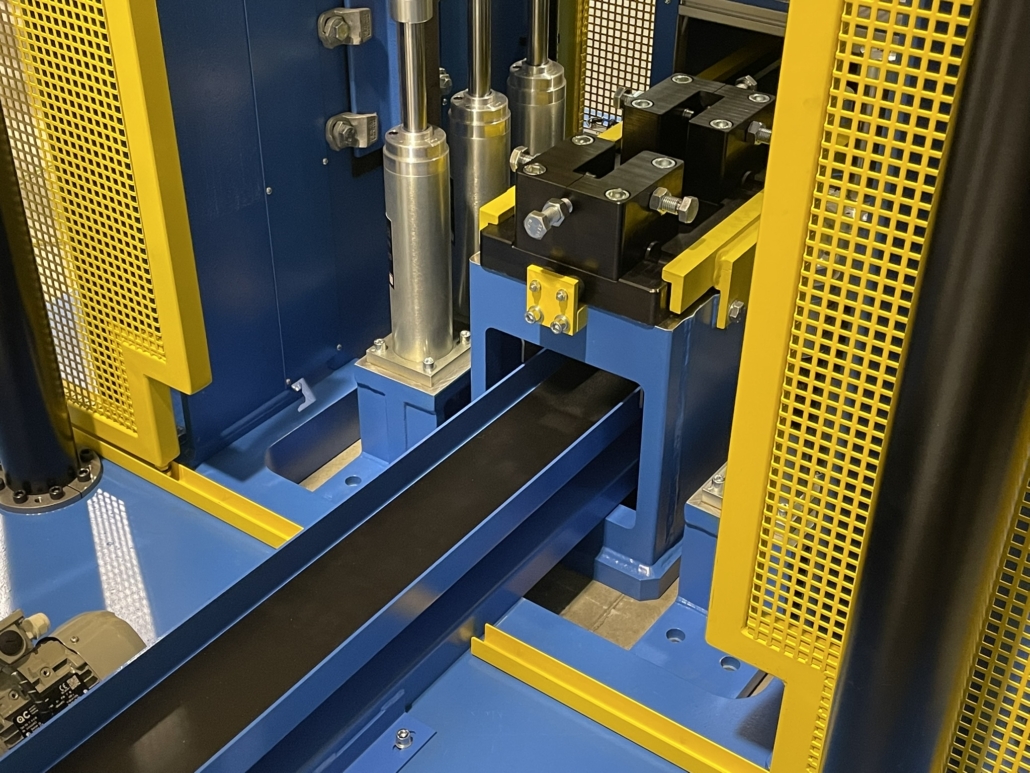

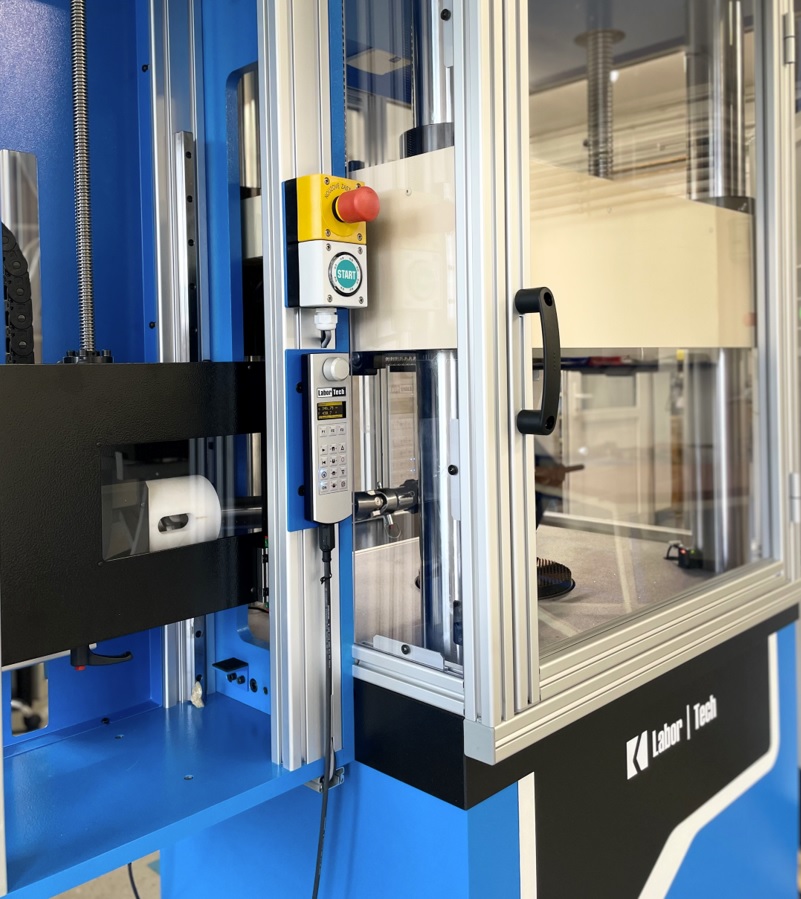

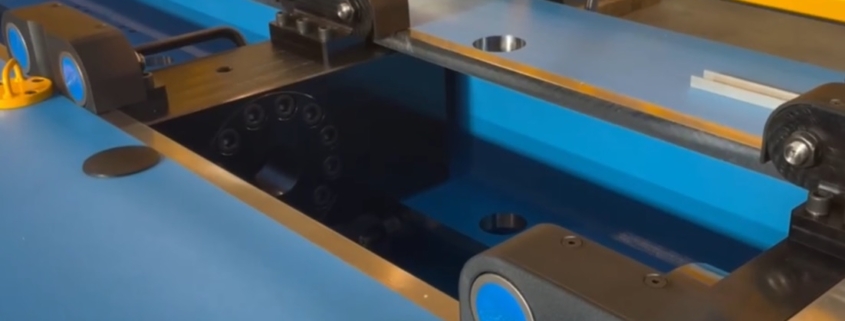

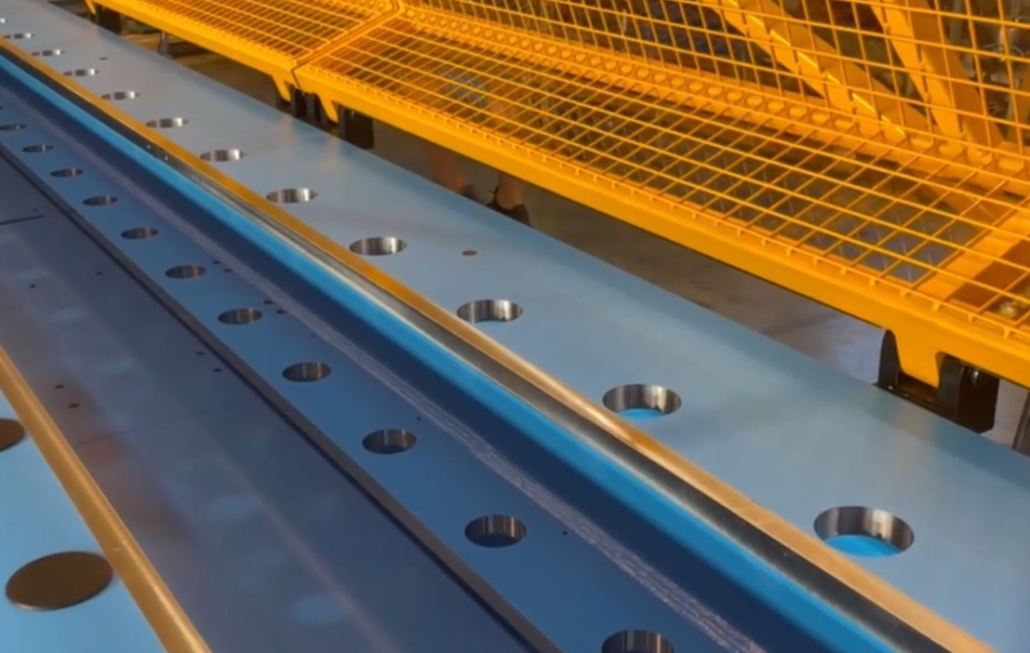

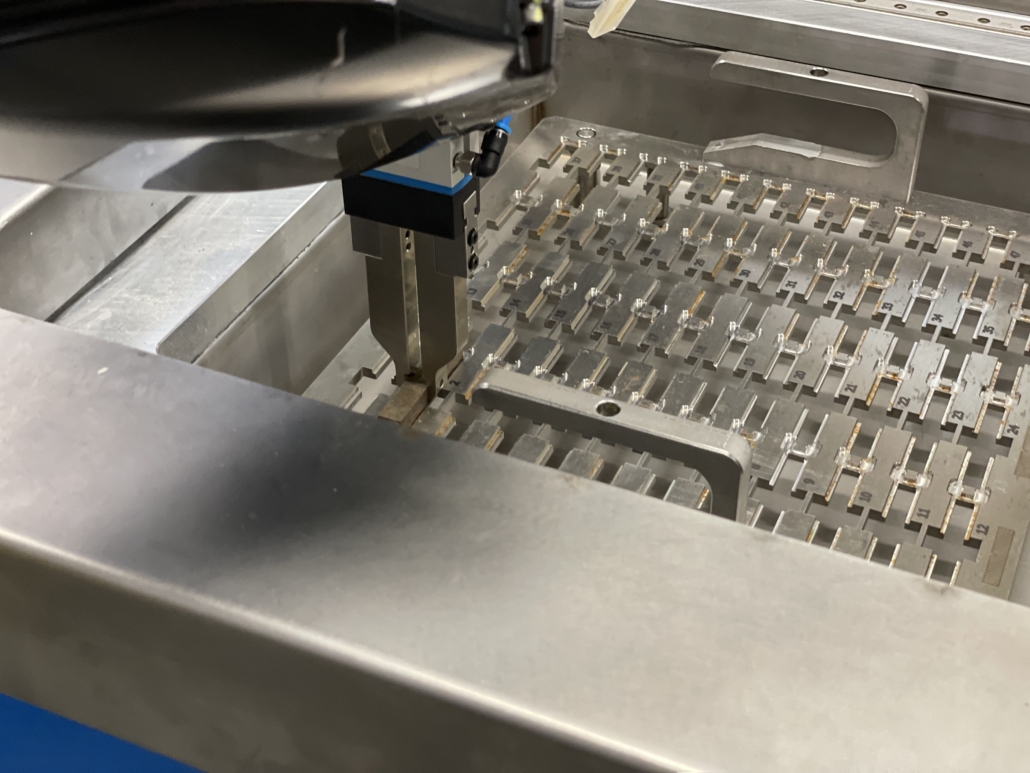

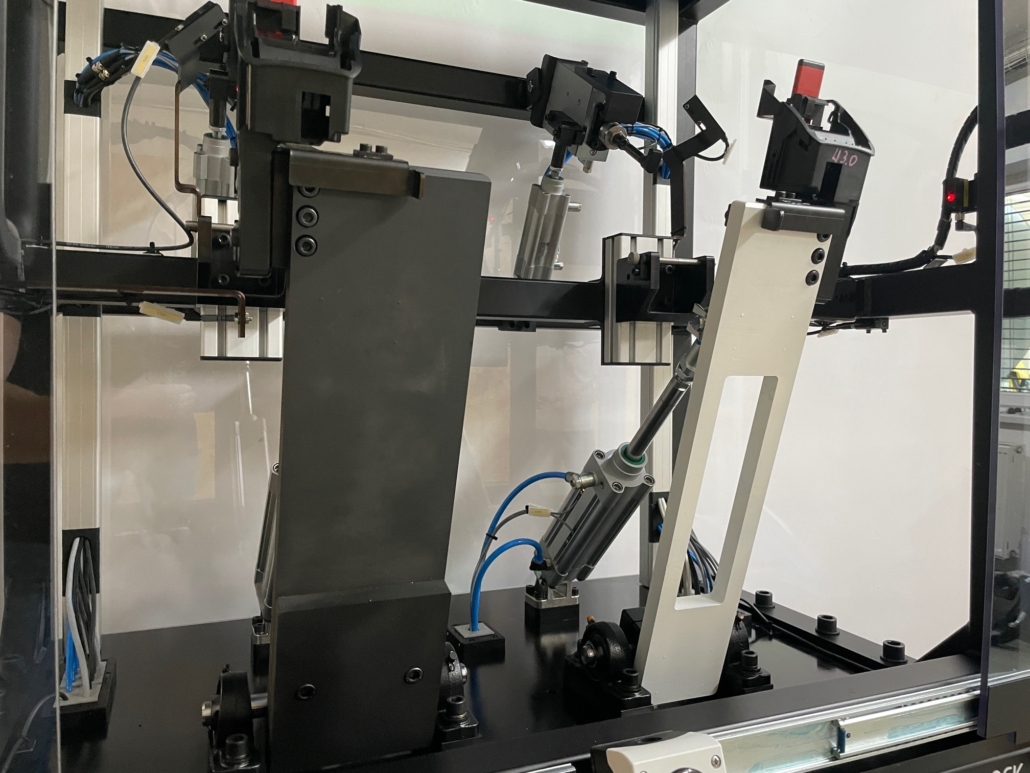

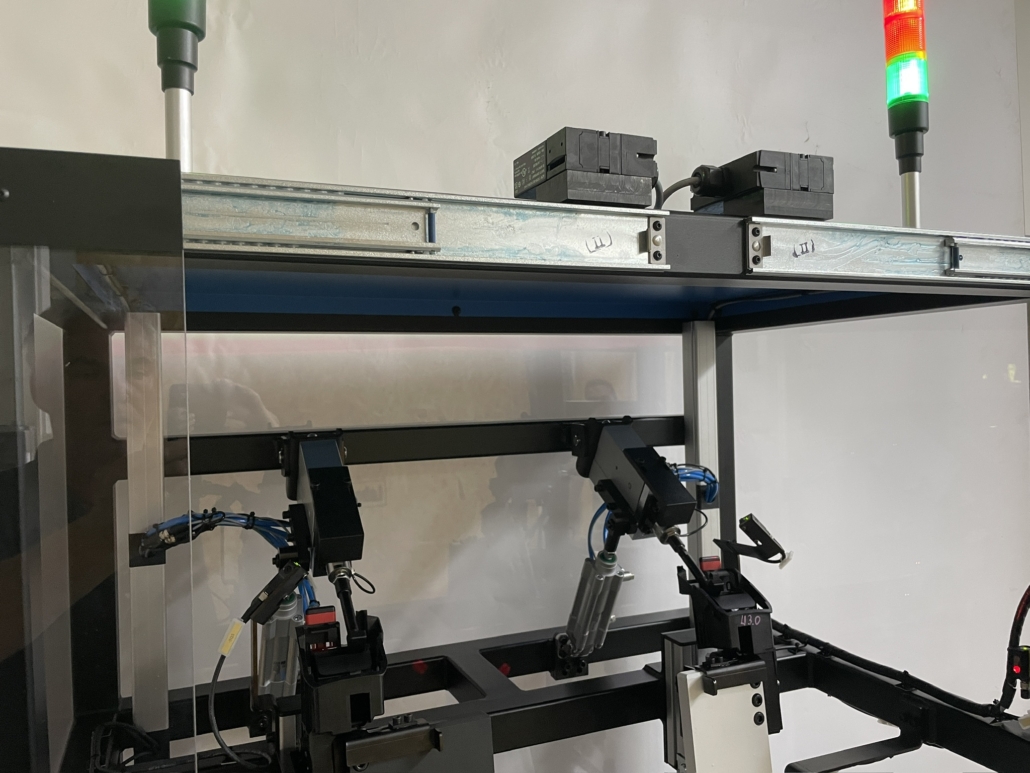

In the automotive industry, the reliability of every component plays a key role. Rear seatback locks must be secure yet easy to operate. For precise and repeatable testing of these mechanisms, the specialized LabTest 6.05.9 – SEAT LOCK machine was developed. This compact test system, featuring a rigid welded frame and a safety enclosure compliant with EN ISO 14120:2017, is designed to verify the release force of seatback locks after dynamic closure at a speed of 1.6 m/s. It supports testing of both left and right seat sides. The required release force for a compliant lock is 45 ±10 N. Simulated seatback mass is 17 kg on the right side and 7.5 kg on the left, with an 8 mm striker that can be adjusted in height by ±4 mm.

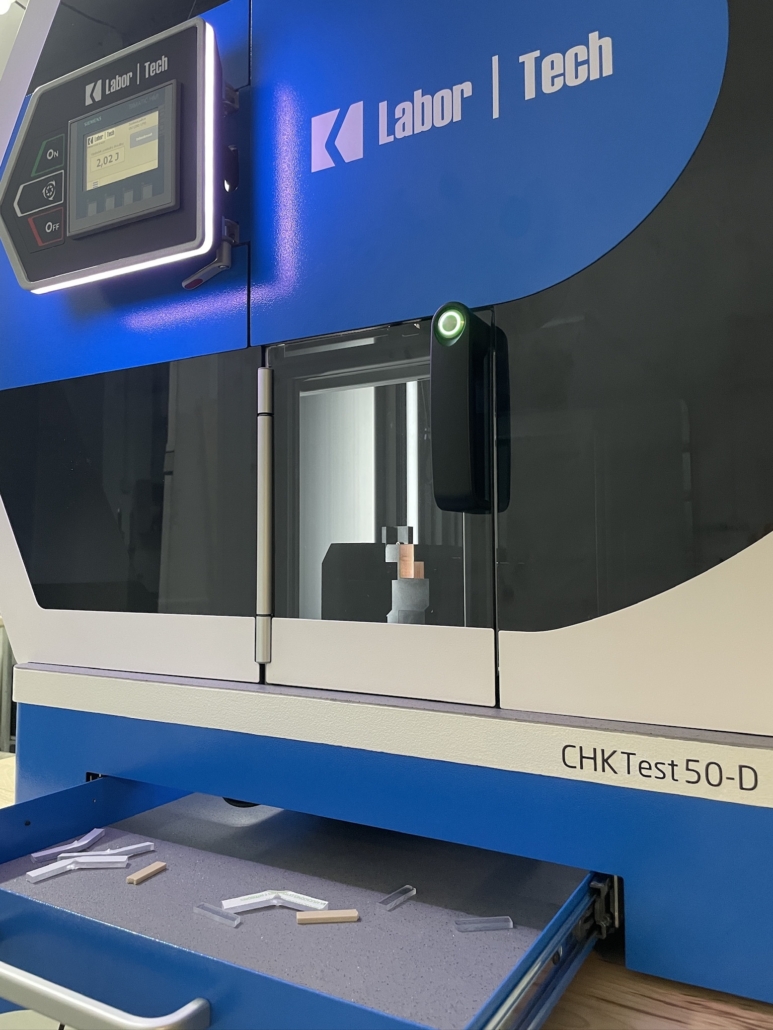

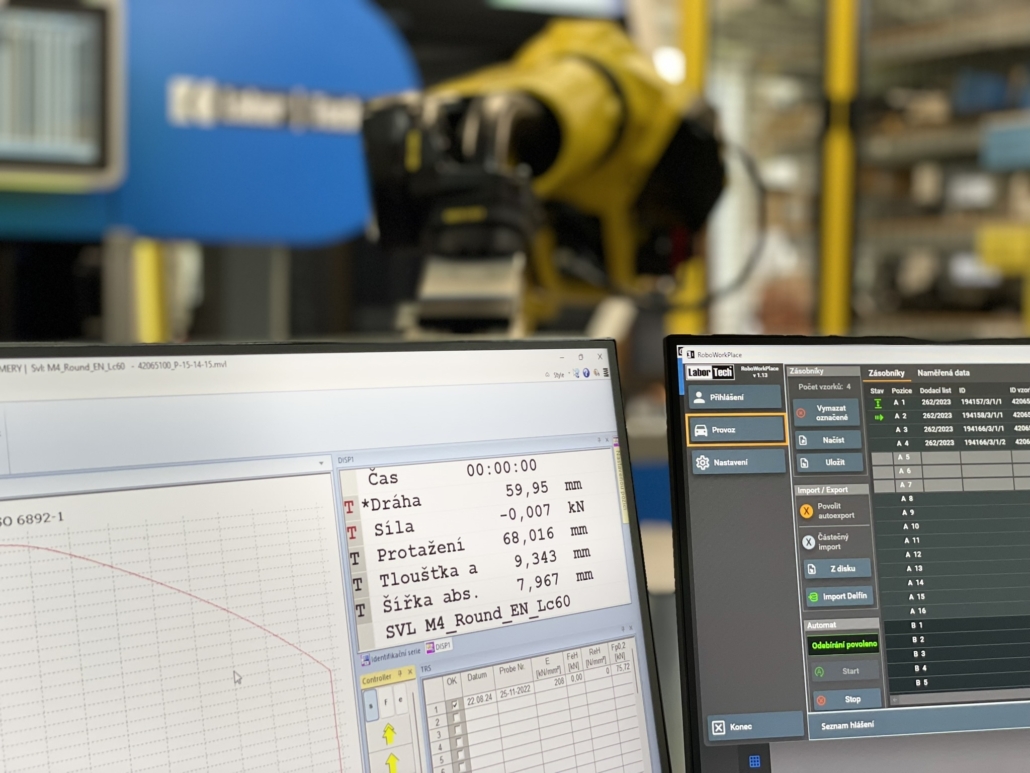

Locks are typically mounted using two M8 bolts tightened to 23 Nm, but automated clamping can also be considered. The ergonomic setup allows operation in a standing position, and the machine is designed with maximum safety in mind, including protection of the handle surface during the unlocking cycle. Test results are clearly indicated—either as a simple OK/NOK signal or with a precise measured force value.

LabTest 6.05.9 – SEAT LOCK is an ideal solution for development and quality control, providing reliable, fast, and safe validation of seatback lock performance.

TEAM LABORTECH