With the world’s leading manufacturer of plastic piping systems, Wavin plastic pipe systems & solutions, we have implemented a project for the production of low-capacity Drop weight tester series DP.2, which will be the current testing laboratory of the production plant in the Czech Republic.

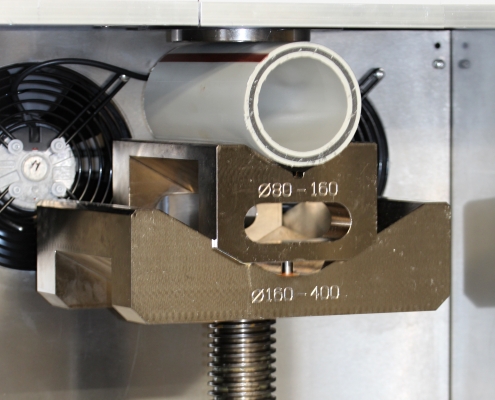

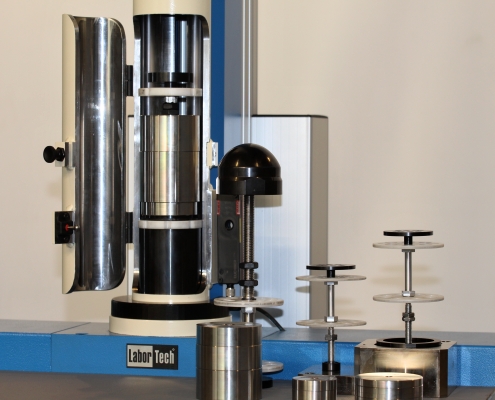

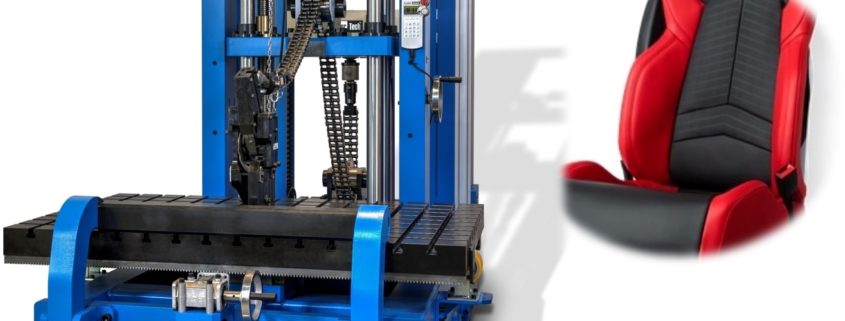

The Drop weight testing machine DPFest 250-2 with nominal energy 250J is used to test the impact resistance of plastic pipes according to DIN UNE EN 744, ISO 3127, EN 1411 and ASTM D2444 standards. The machine is equipped with a number of test strikers by additional test weights and special conical fixtures, which allows a wide range and variation of tests according to different types of plastic pipe diameter. A temperature chamber is also incorporated in the machine frame, capable of temperature adapting the test environment and the tested piping according to the required temperatures.

We bring our many years of experience to your ambitious projects …

As part of the complexity of testing this type of plastic pipe, as set by the standards, it was necessary to equip the machine with another external temperature chamber, in order to achieve maximum authenticity by simulating sudden changes in temperature of test specimens (tested pipe).

High and user-friendly operator comfort meeting all safety regulations …