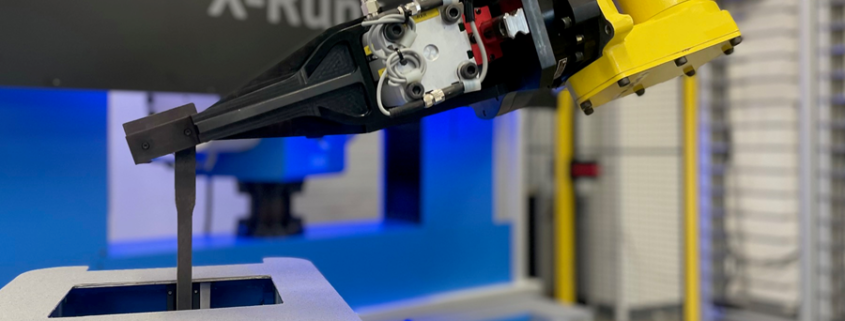

At the end of 2022, we can boast a beautiful project of the X-RUNNER robotic workplace – LabTest 6.600E.3, which we produced and delivered to our customer within 3 months.

This robotic system boasts two novelties:

It automatically distinguishes different types of samples – flat, segmental and round, on which it performs differential measurement of sample dimensions using an intelligent laser sensor with a repeatability of 0.5 μm. The measurement is compact, accurate and fast unlike mechanical measurement used by other companies.

Using the DOUBLE ONE 1 camera system, which allows to measure the relative elongation of segment samples including their contraction according to a special algorithm. All VIDEO EXTENSOMETER measurements are in accordance with EN ISO 9513.

The robotic workplace system consists of the following parts:

LabTest 6.600 testing machine with hydraulic grip grip

Non-contact sample dimensional measurement system – LME 50

DOUBLE ONE 1 camera systems for measuring proportional elongation and contraction.

Hybrid hydraulic unit of the HAG series with controlled pressure.

FANUC robot with a special gripper for samples up to 50 mm thick.

Container system designed for 112 samples regardless of shape and size.

.

We are very proud to have been able to deliver the X-RUNNER robotic workstation with innovations for 2023 in such a short time. I would like to thank everyone who participated in this project.

Vladan Dušek – director of LABORTECH.