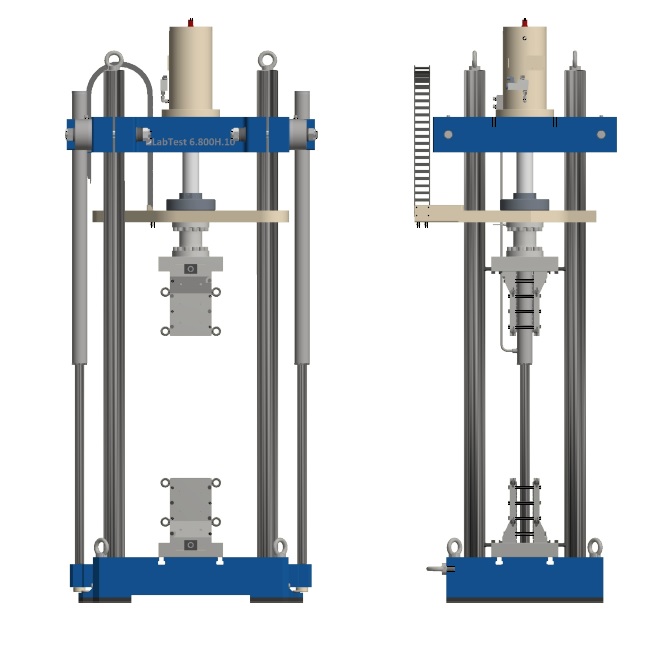

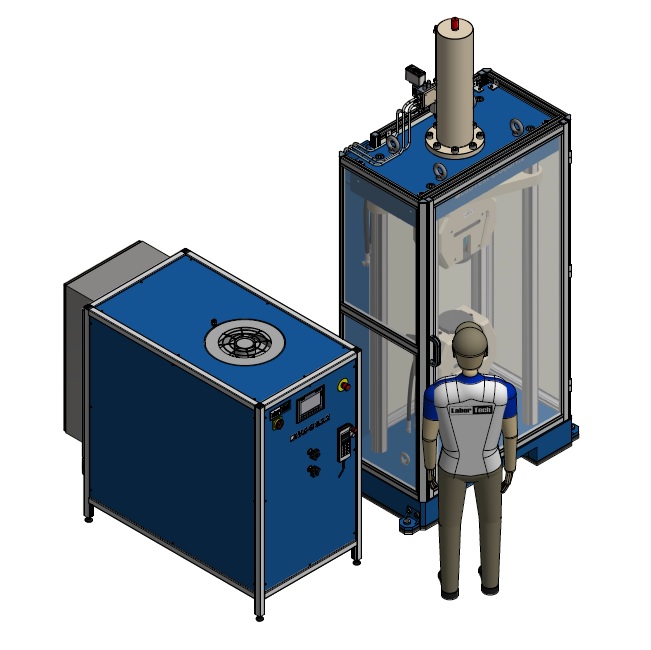

H.1 – H.2 – Static vertical hydraulic testing machines up to 5MN

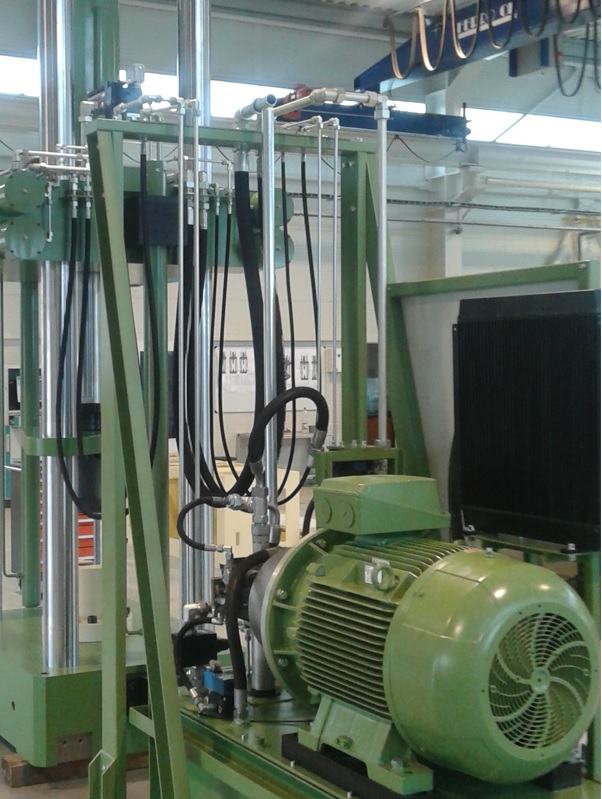

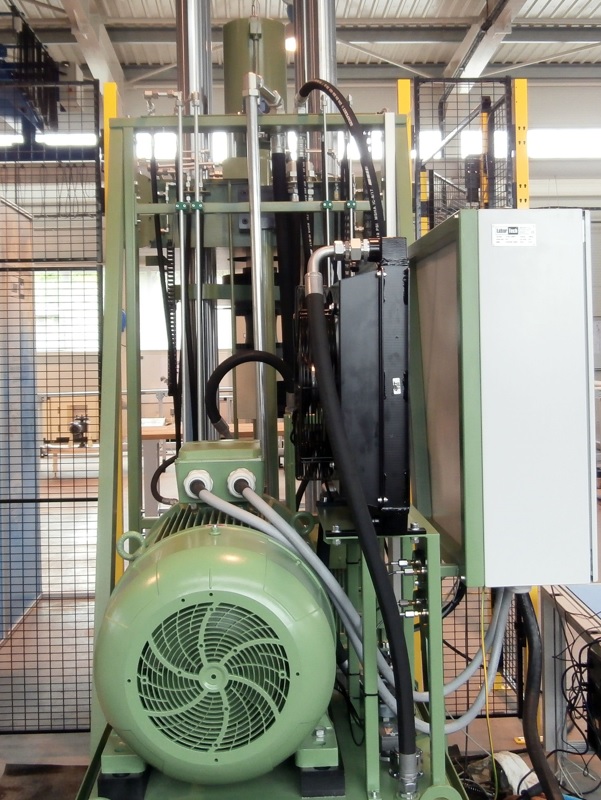

The H.2 servo-hydraulic testing machines up to 5MN are designed for safe and efficient testing of materials and whole products in tension, pressure, bending and special testing of high strength materials. This range of machines is characterized by extremely high stiffness and mechanical resistance of the frame. The basic equipment of the machine includes a central silent and economical hydraulic unit with hybrid control of hydraulic grips with diagnostics HALT 18 – SIEMENS.

Download:

Download:

Download:

Download:

MEZERA

Key features of the H.1 and H.2 series

MEZERA

MEZERA

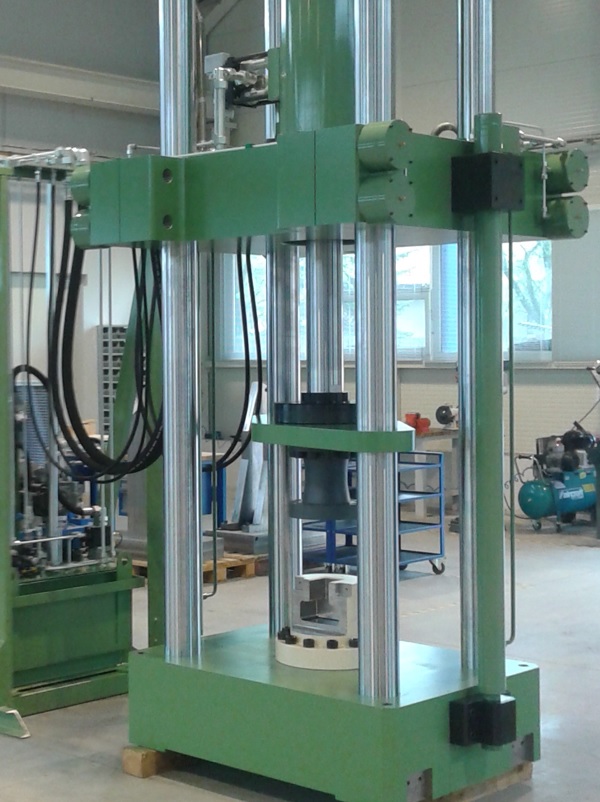

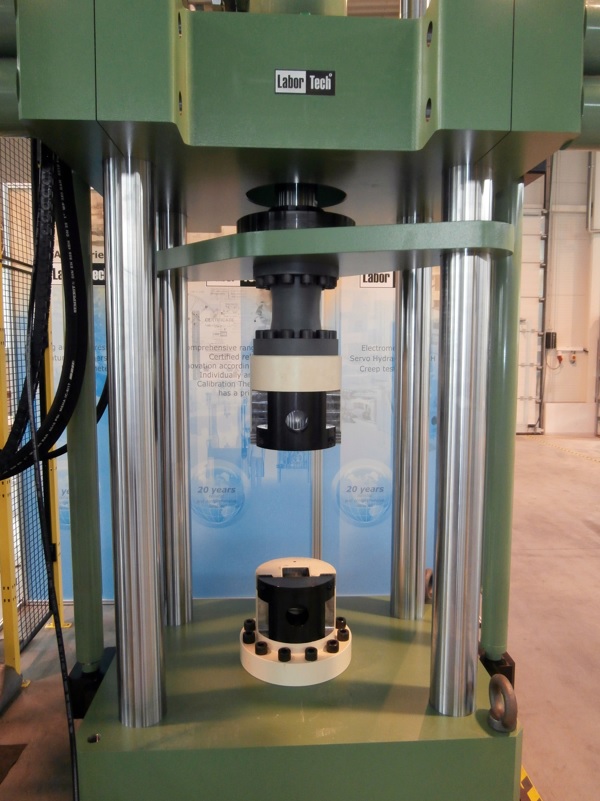

- Robust vertical stand design with high rigidity, mechanical resistance and durability with two – H.1 and four – H.2 hard chrome guiding rods and fixed crossbar controlling.

- Modular design of machines with fixed crossbar – series 00 or adjustable crossbar – series 01

- Powerful compact hydraulic units of the HAS series with low noise level <65 dB.

- HALT 18 hydraulic unit diagnostics controlled by TOUCH LCD SIEMENS as standard.

- Control of the crossbar movement by a proportional valve with the possibility of control in the force and position loop.

- The H.1 and H.2 series machines comply with all the above-mentioned EC directives on machinery and equipment and work in accordance with the new safety functions according to EN ISO 13850:2015.

- Load cells working in the accuracy class according to EN ISO 7500-1, ASTM E4 with the possibility of linearization.

- The machine is controlled by measuring and control electronics of the EDCi series with a sampling frequency of 2.5 or 10 kHz. Analog signal resolution level ± 250,000 divisions.

- Possibility of extending the 01 series frame by automatic hydraulic movement and clamping of the crossbar.

- Complete test evaluation and management is provided by Test & Motion material testing software.

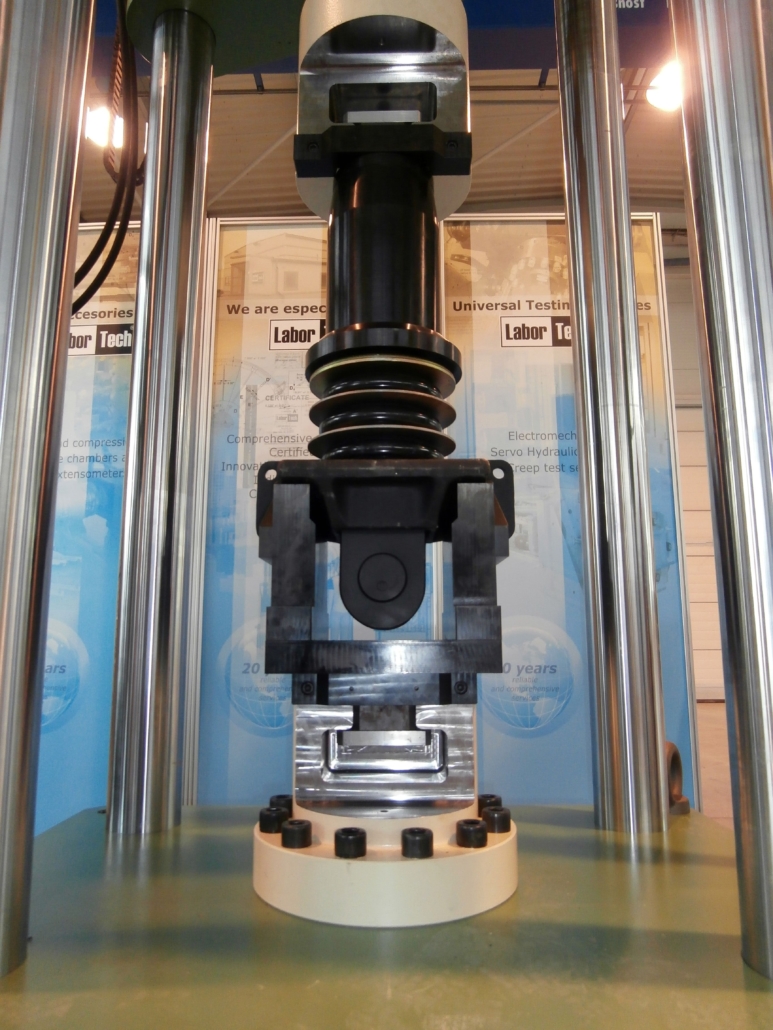

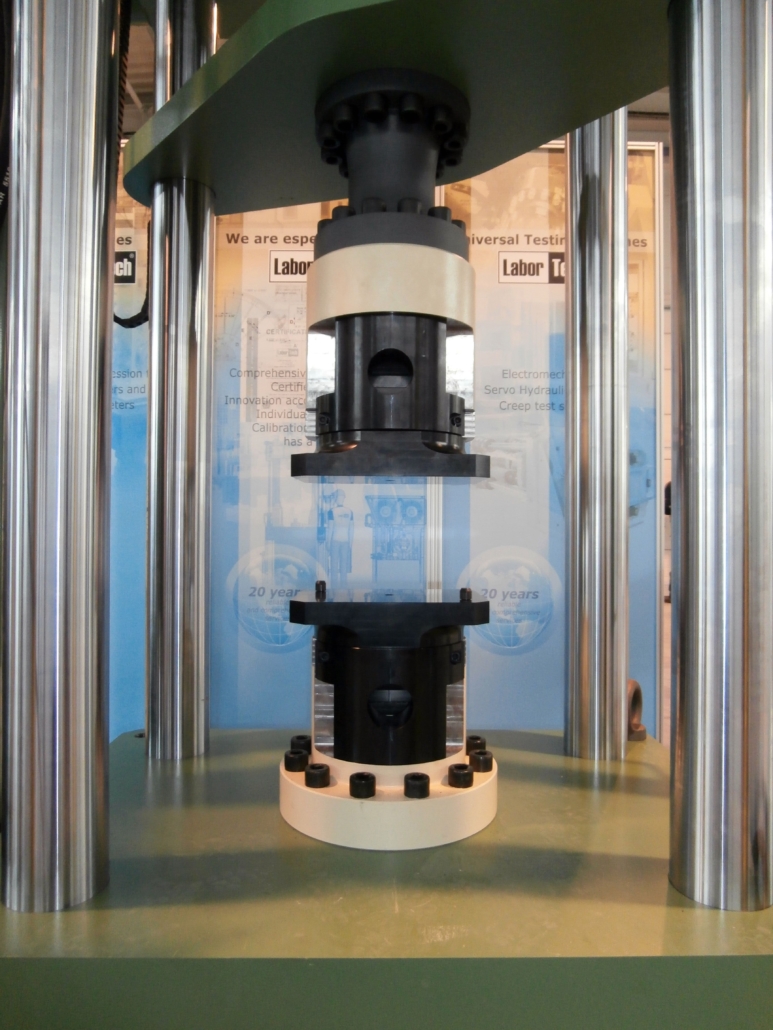

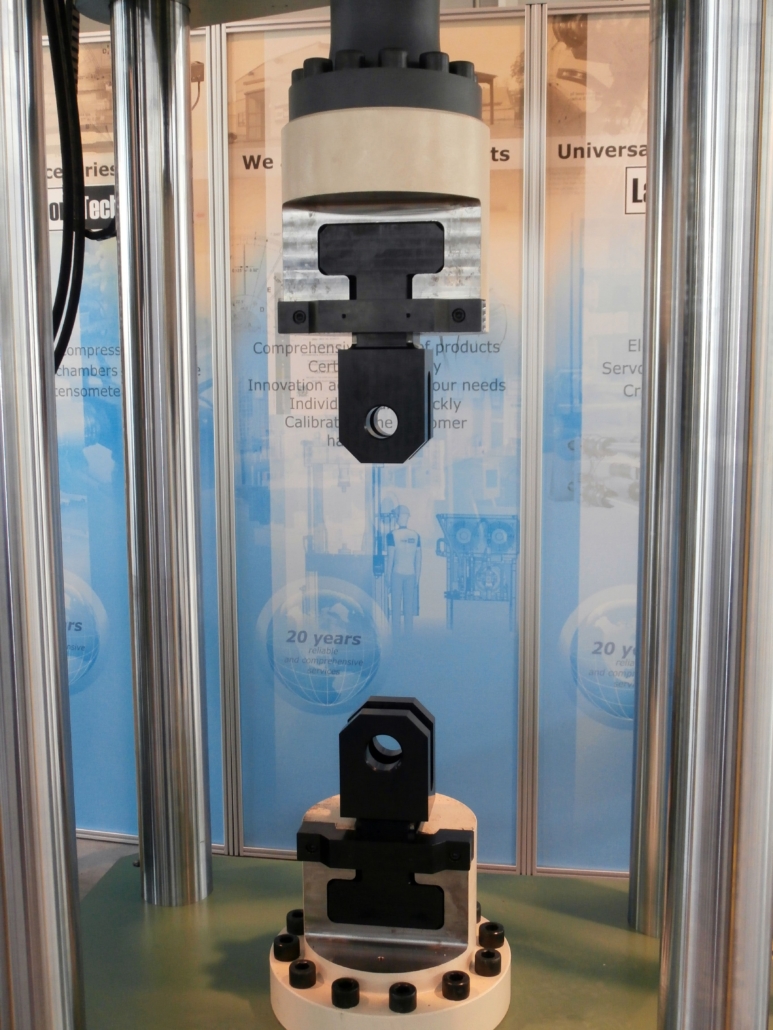

- Integration of hydraulic grips with wedge or side pressure, various fixtures, etc.

- High-precision tests with temperature chamber or high-temperature furnace.

MEZERA

VIDEOS of LabTest testing machines series H.1 and H.2

Tensile test on a normalized sample with extensometer

Tensile test of high-strength materials in hydraulic wedge jaws according to EN ISO 6892-1 with contact extensometer until complete tearing.

Tensile test on a round high strength sample

Tensile test of high-strength materials in hydraulic jaws with lateral pressure according to EN ISO 6892-1.

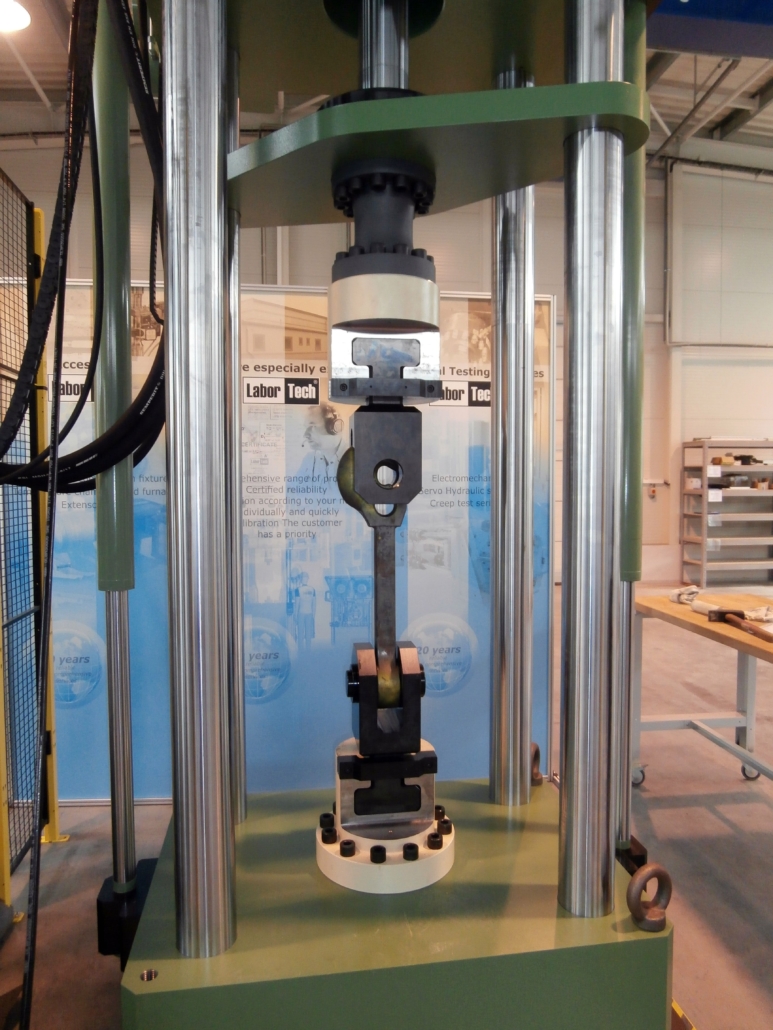

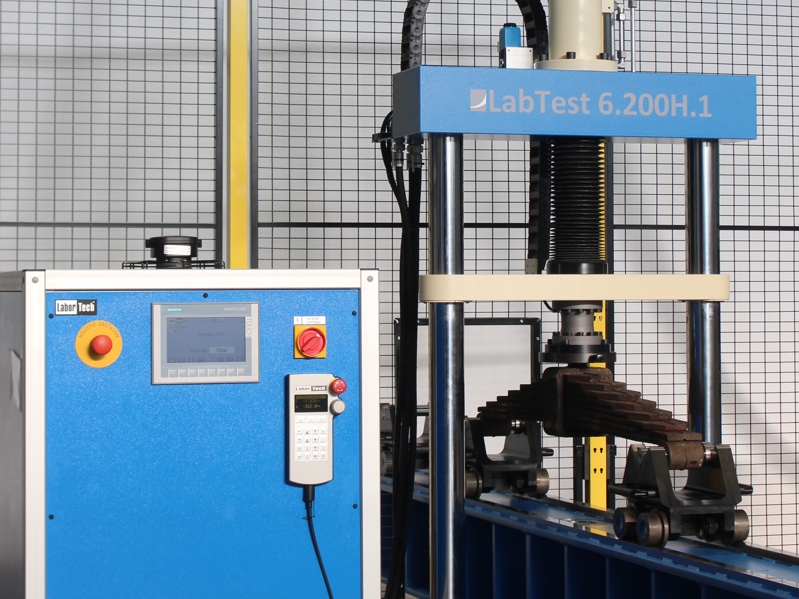

ENGINEERING industry – testing of leaf springs

Testing: parabolic leaf springs, trapezoidal leaf springs and helical rolled springs. Standards: EN 10092-2, EN 13906-1, EN ISO 2162-1.

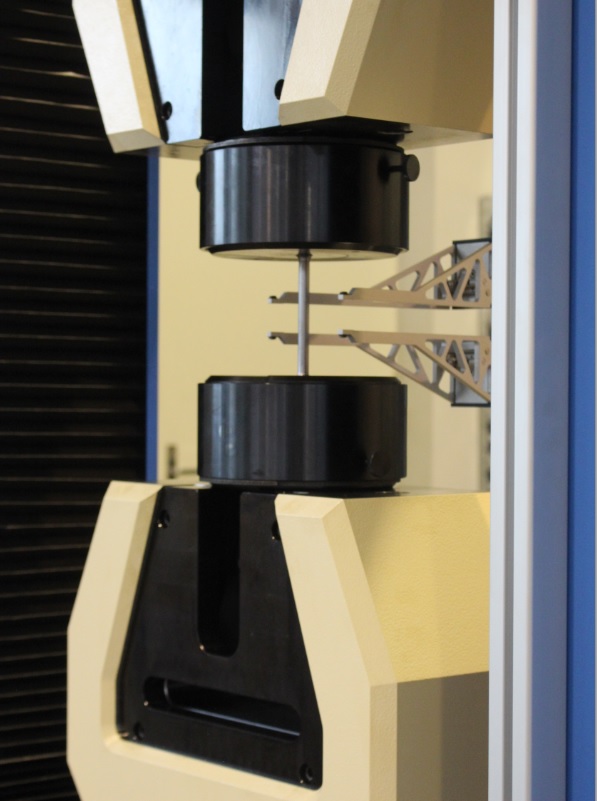

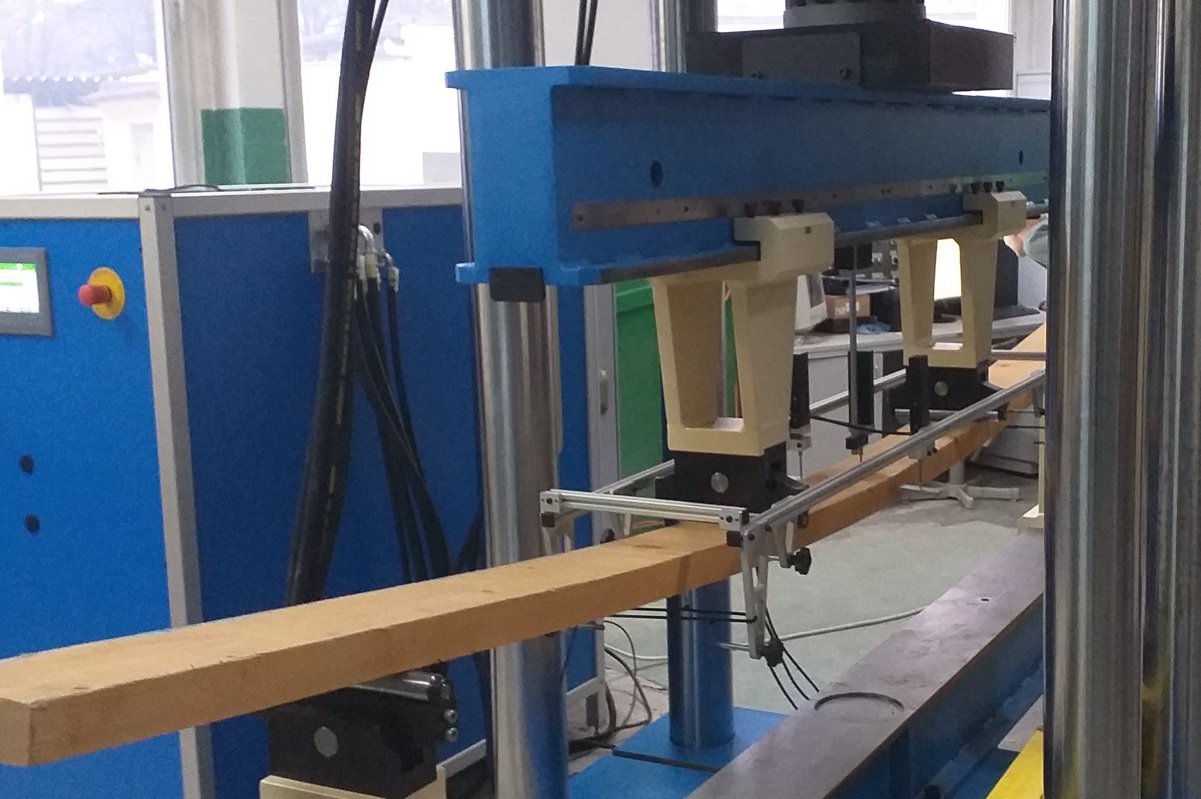

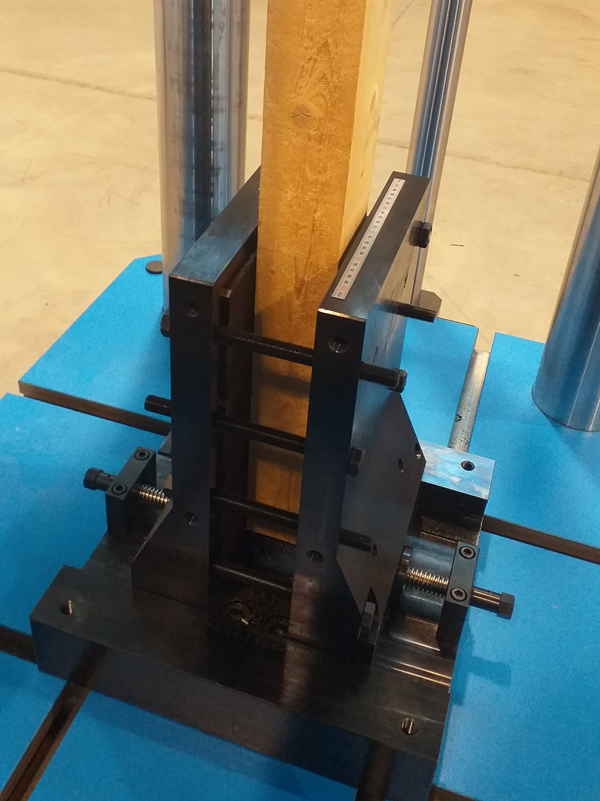

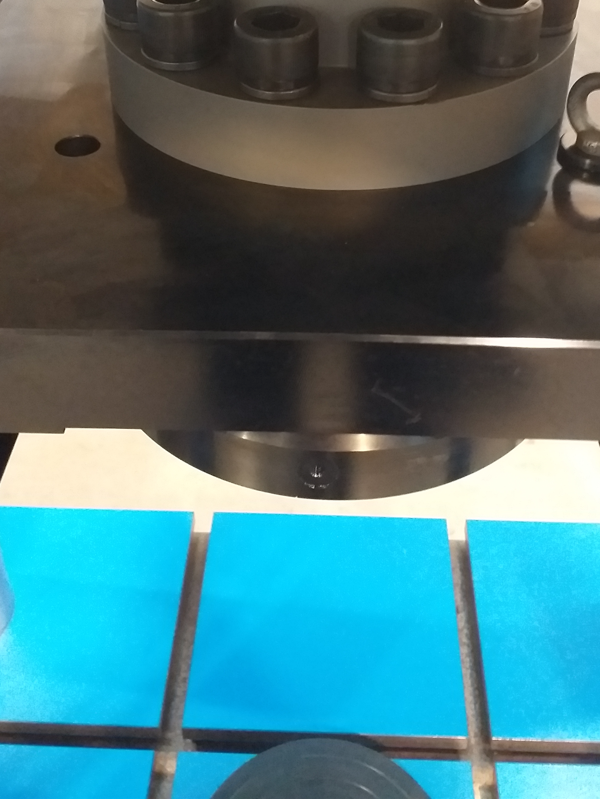

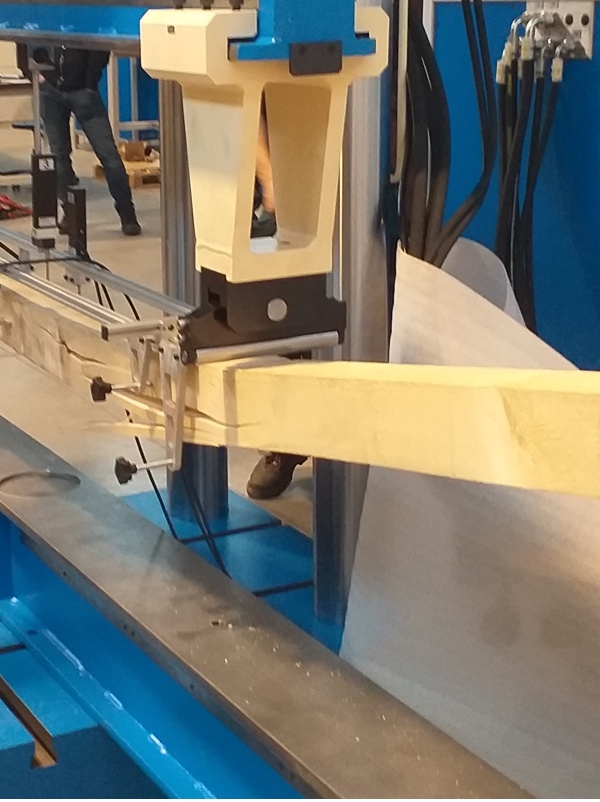

3 and 4 point bending test on wooden beams

3 and 4 point bending test on the LabTest 6.500 kN H.1 testing machine designed for static load tests of wooden structures in accordance with the standard with EN 380: 1993.

Tensile test on a normalized flat sample

Tensile test of high-strength flat sample in hydraulic wedge jaws according to EN ISO 6892-1.

MEZERA

Do you have questions about our products?

Feel free to contact our product experts.

We look forward to your interest.

–

MEZERA

Testing on LabTest machines with various accessories

You can test anything with our wide range of accessories…

Tests with extensometers and measuring probes

Tensile test with extensometers in accordance with EN ISO 9513 and EN ISO 6892-1.

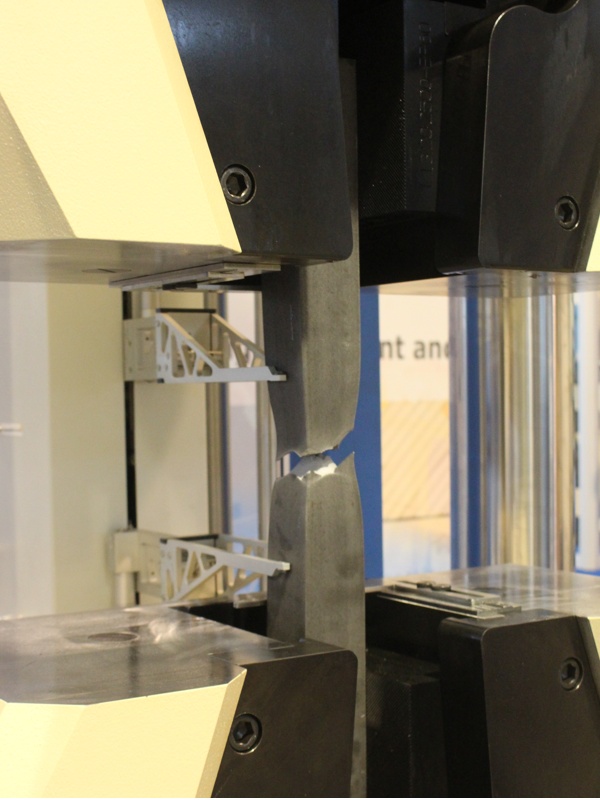

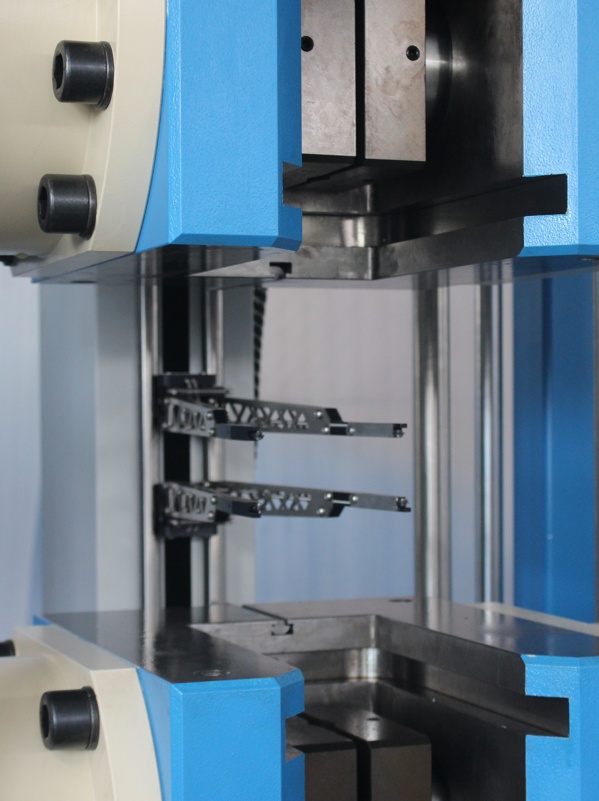

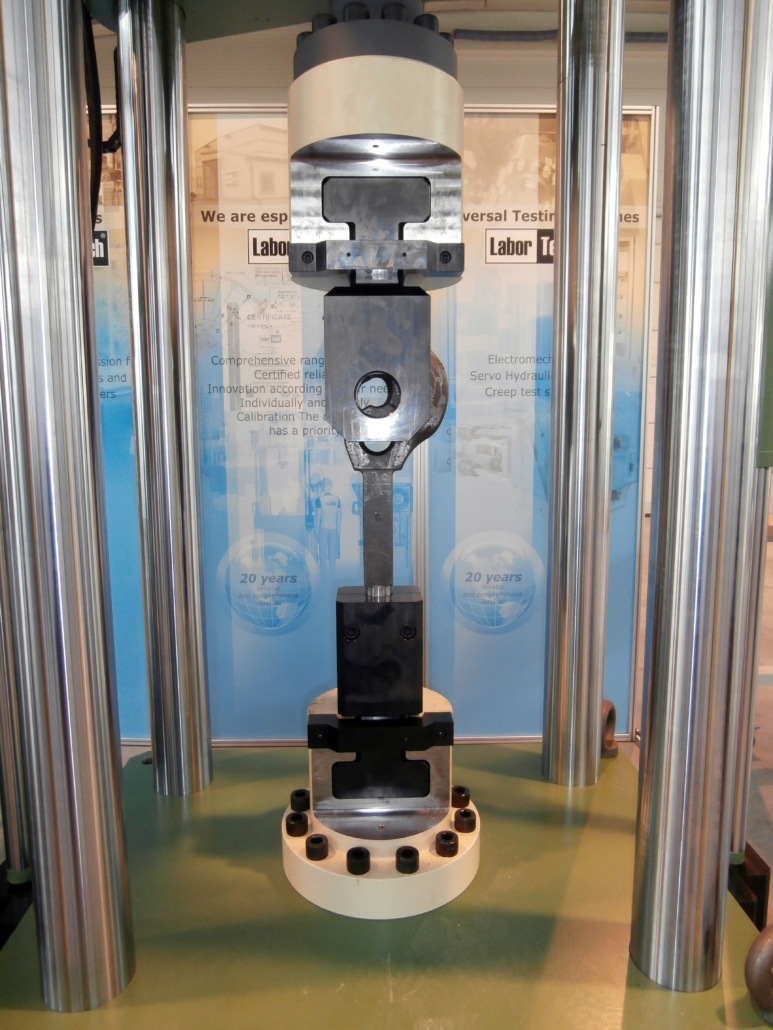

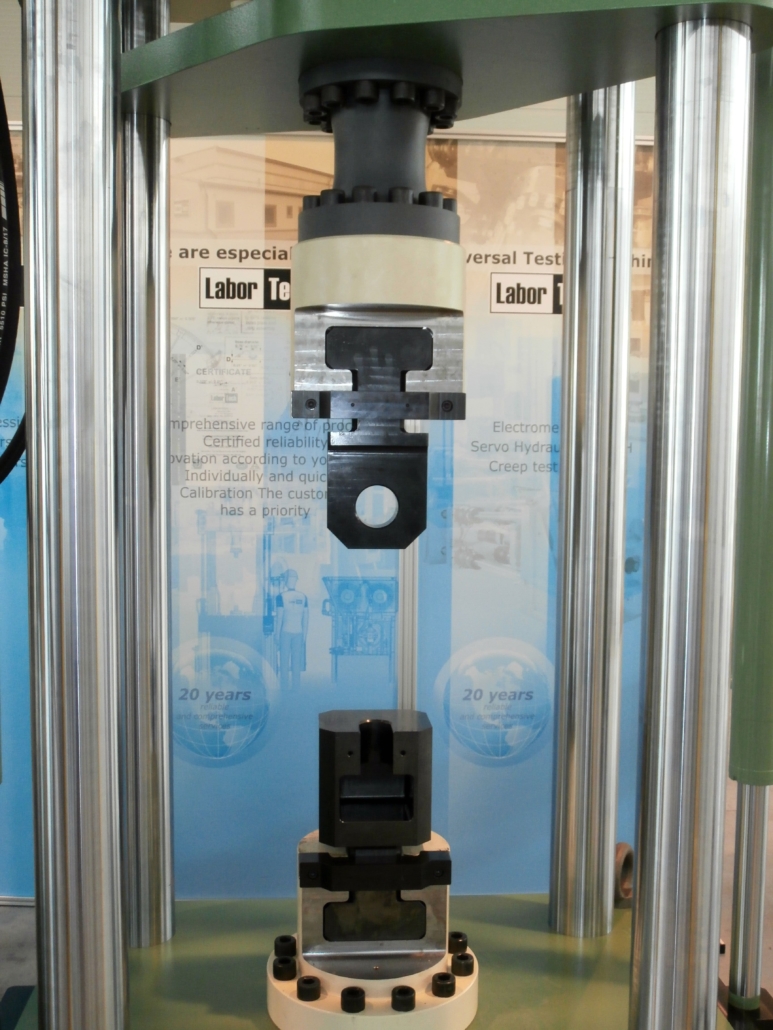

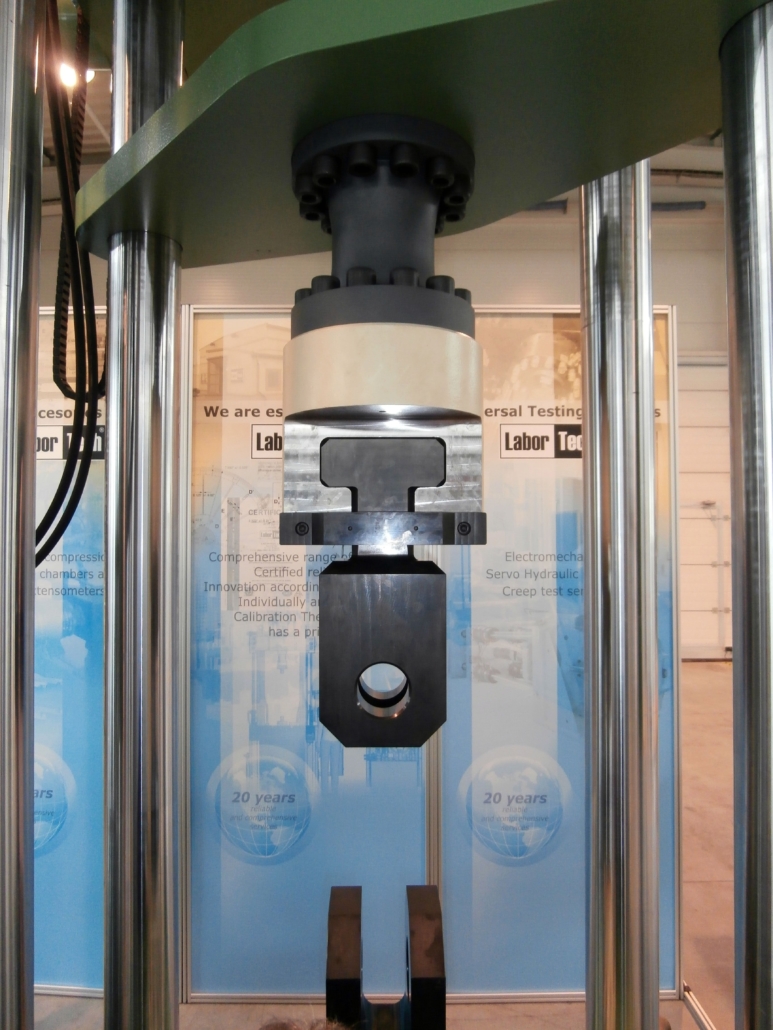

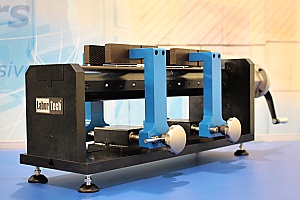

Test with various jigs and clamping grips

Various types of clamping grips and test fixtures for fixing metals, carbon, plastics, laminates, etc. for tensile, compressive, bending and torsion tests according to EN 6892-1, EN6892-2, etc.

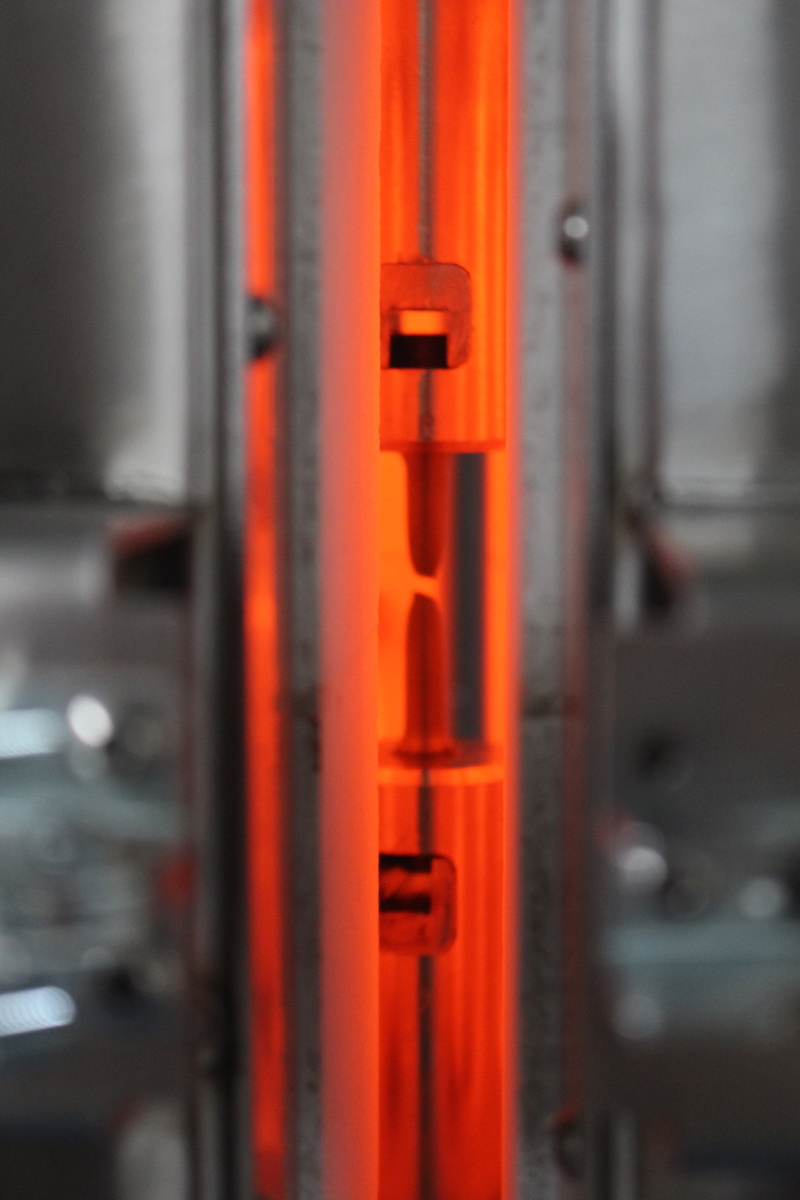

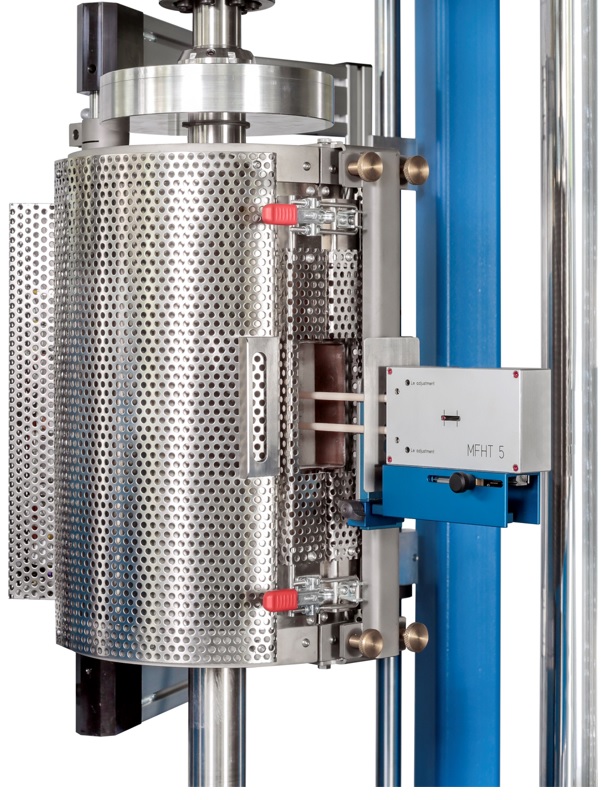

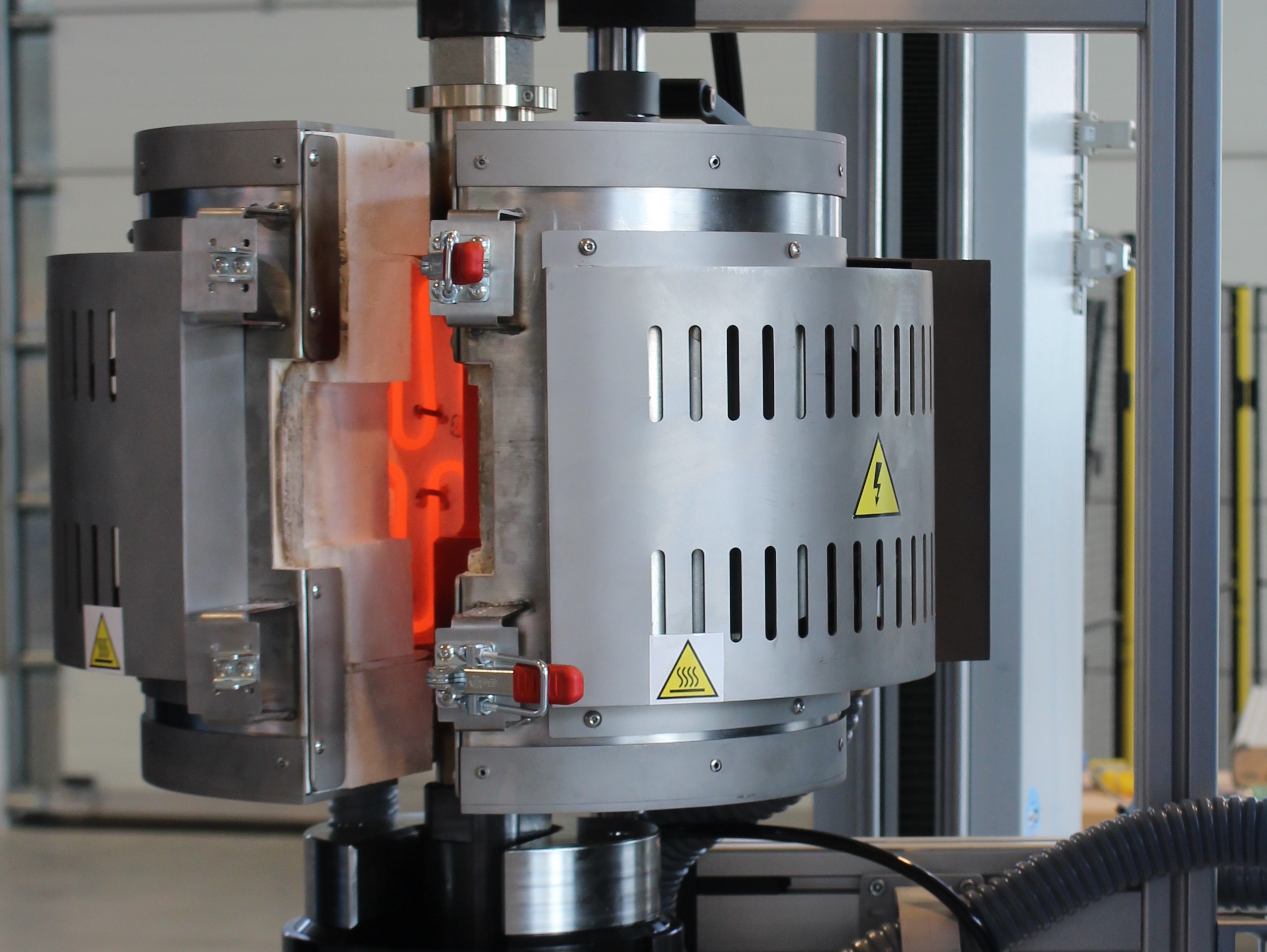

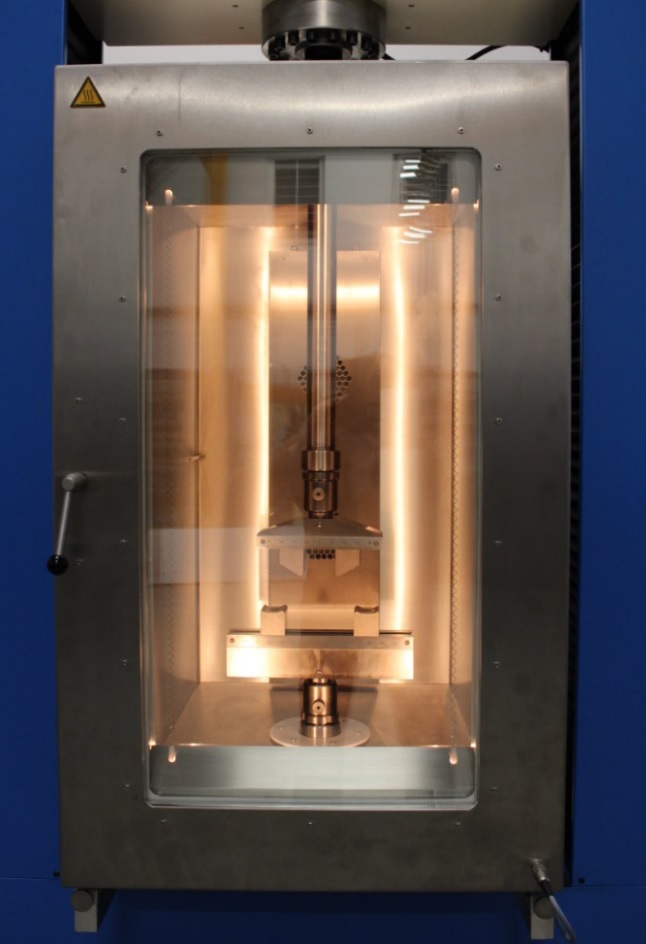

Test with high temperature furnace and temperature chamber

Tensile tests with high temperature furnace up to 1600 ° C according to ISO 6892-2, temperature chamber with temperature ranges from -196 ° C to 450 ° C.

MEZERA

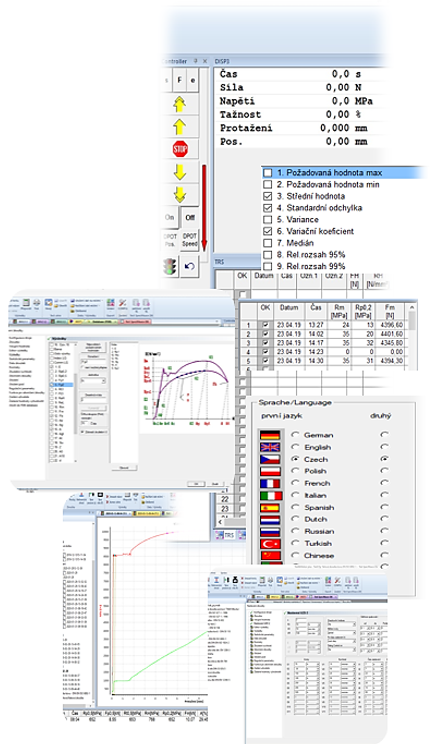

Test&Motion+ software

Intuitive software for tensile, compressive and bending tests…

Test & Motion + – BASIC – intelligent, intuitive and powerful software that will help you increase productivity and testing quality in your test rooms and testing laboratories. You can streamline, refine, and accelerate your testing and adapt your testing environment to make it easy for operators to measure the mechanical properties of tensile, flexural, and torsional materials with EN, ISO, DIN, ASTM, and GOST standards.

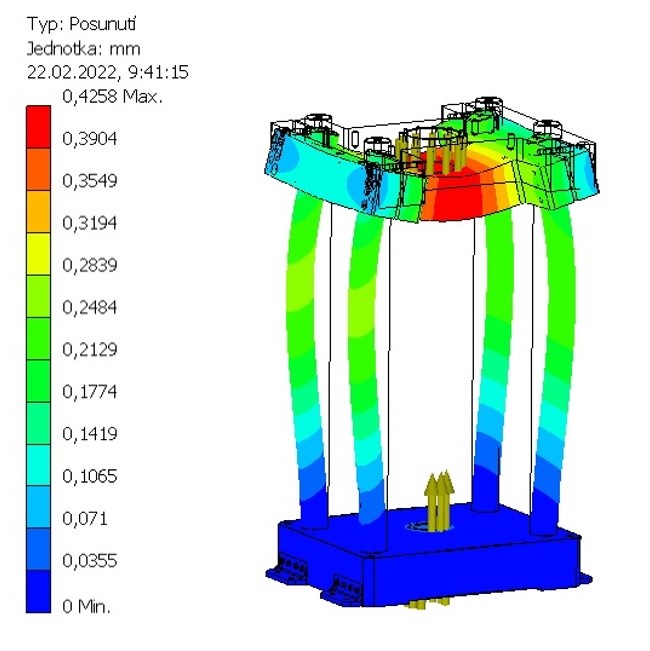

WE OFFER INNOVATION AND TECHNICAL SOLUTIONS

Customer solutions – uniqueness until to the last detail

- Our specialists are able to custom design and manufacture a testing machine or automated system with a high degree of quality and uniqueness

- In the case of technically advanced products, optimization often begins with details and in 3D STEP formats or DWF viewers.

- When developing LABORTECH products, we place great emphasis on the quality, design and affordability of our products.

- In the design of machines and systems, we pay attention to the minimum environmental impact and ECODESIGN in accordance with the standard EN ISO 14001: 2016.

- We verify the accuracy, reliability, durability and mechanical resistance of our machines in a test and calibration center.

MEZERA

Interesting customer applications

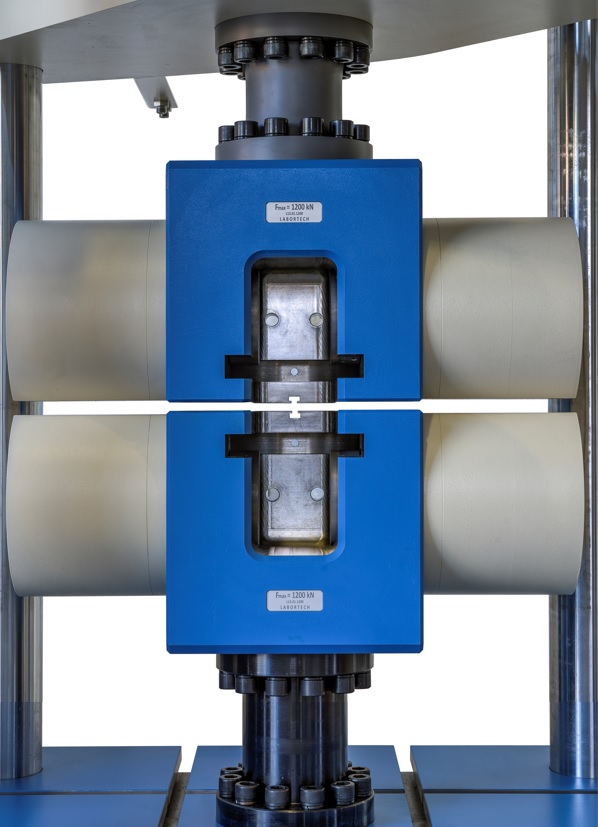

RAILWAY industry – high-speed testing of railway parts

Servohydraulic testing machine LabTest 6.2000H.2 with high test speed – 25 mm / s for testing bumpers, drawbars, screws and towing hooks for trucks and passenger rail vehicles and locomotives in accordance with standards EN 15551, EN 15020 + A1, EN 15551EN 15551EN 15551

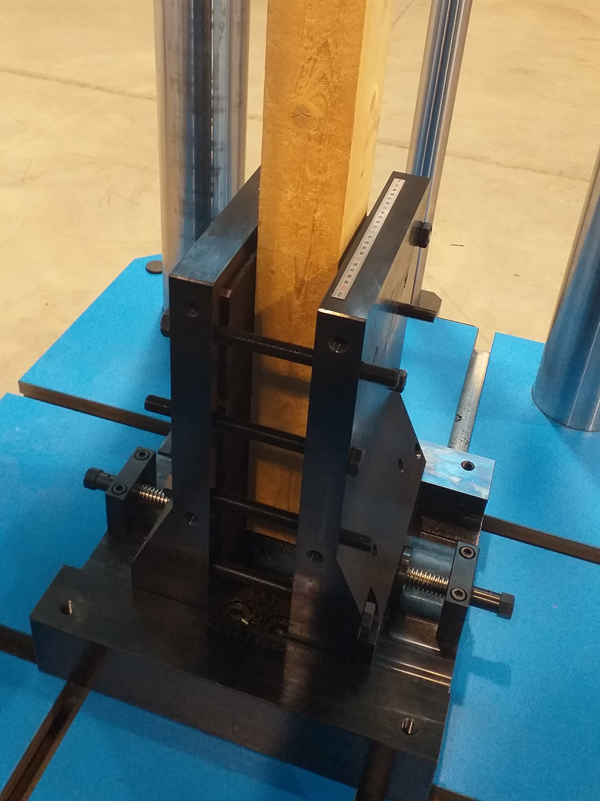

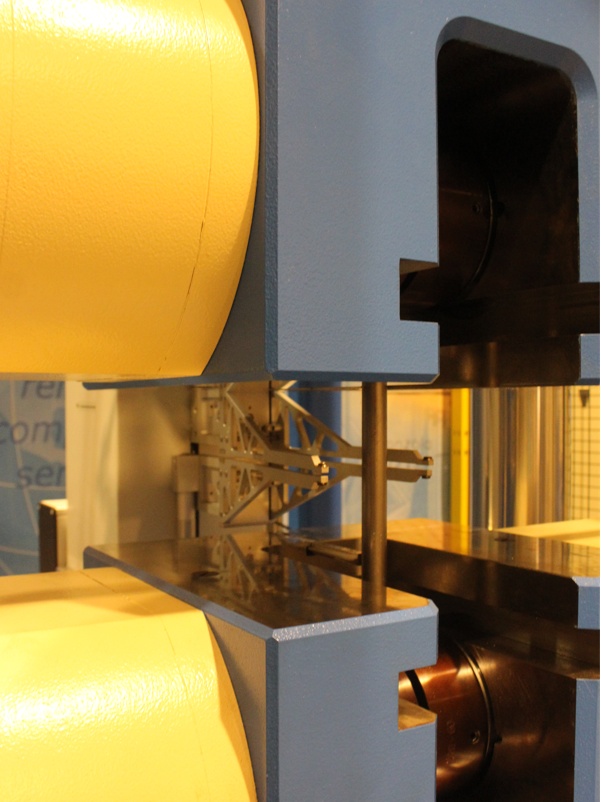

WOOD INDUSTRY – testing of wooden beams

Servohydraulic testing machine LabTest 6.8000H.2 designed for testing wooden beams in tension and 3 and 4 point bending in accordance with standards ČSN EN 380 and ČSN EN 310 or for railway applications – track – wooden cross and switch sleepers ČSN EN 13145 + A1

ENGINEERING industry – testing of high-strength chains

Servohydraulic testing machine LabTest 6.1000H.2 with special grips designed for testing short link chains for lifting purposes according to ČSN EN 818-1, medium tolerance chains for chain slings class. 8 – ČSN EN 818-2, lashing chains class. 8 – ČSN EN 818-4 etc.

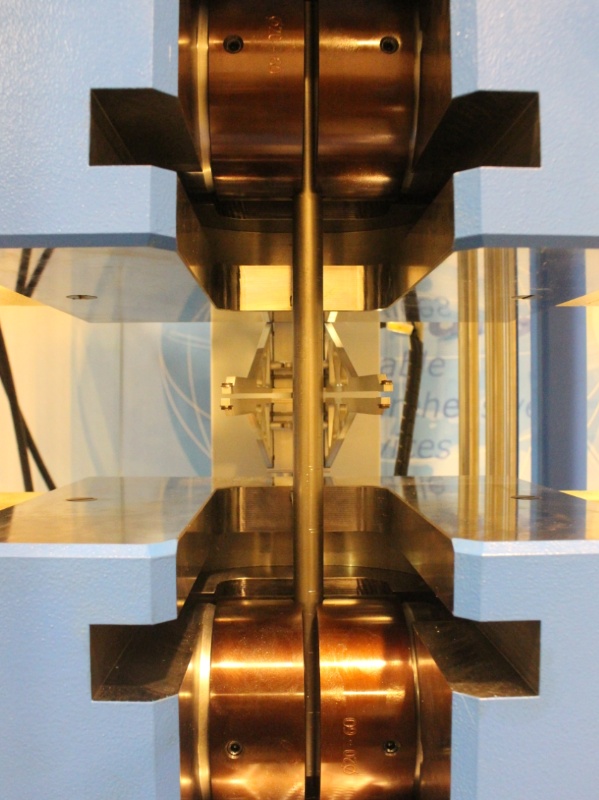

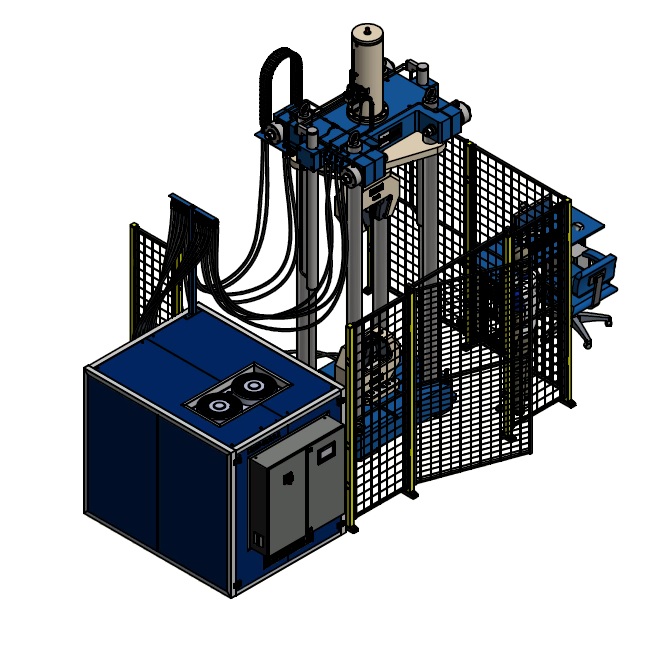

ENGINEERING industry – testing of leaf springs

Servohydraulic testing machine LabTest 6.200H.1 designed for testing: parabolic leaf springs, trapezoidal leaf springs and helical rolled springs. Standards: EN 10092-2, EN 13906-1, EN ISO 2162-1. The construction of the machine is in a semi-automatic design as well as the performance of the test itself.