Contact

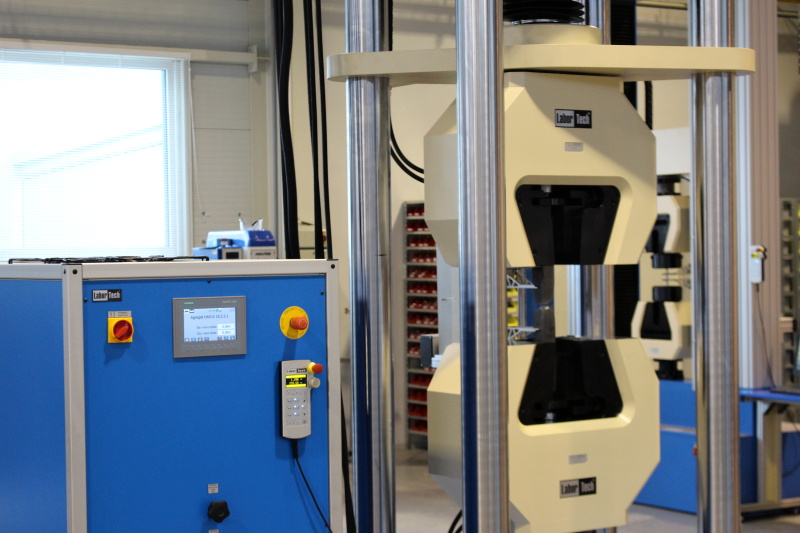

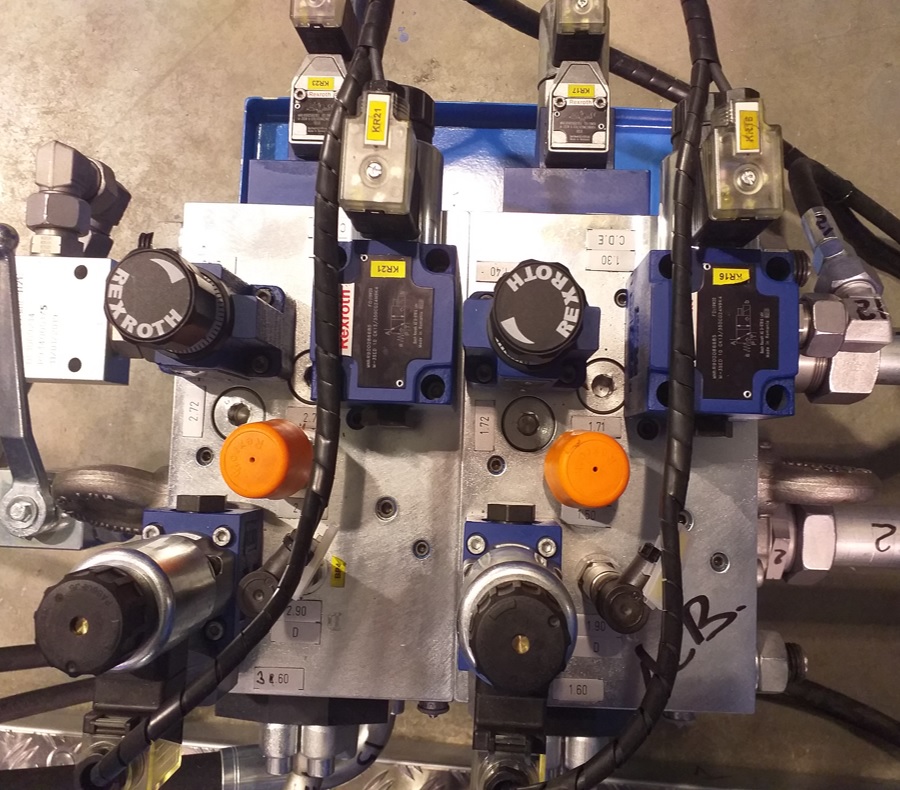

HAG hydraulic units designed for controlling hydraulic jaws

LABORTECH HAG: clamping force that holds, silence that you can hear…

HAG 3 - SIMPLE-V - for wedge jaws - NEW DESIGN

The HAG 3 – SIMPLE hydraulic unit is designed specifically for operating hydraulic wedge jaws. This unit features a new design, minimal noise and easy operation, making it the ideal choice for applications where efficiency and quiet operation are required.

Main specifications:

- Constant pressure: 160 bar

- Status indication: Basic information about the unit status displayed on the SIEMENS LOGO display

- Hydraulic hoses: Set of hoses up to 3 m long for connection to the jaws

- Pressure indicator: Manometric pressure indicator in the system

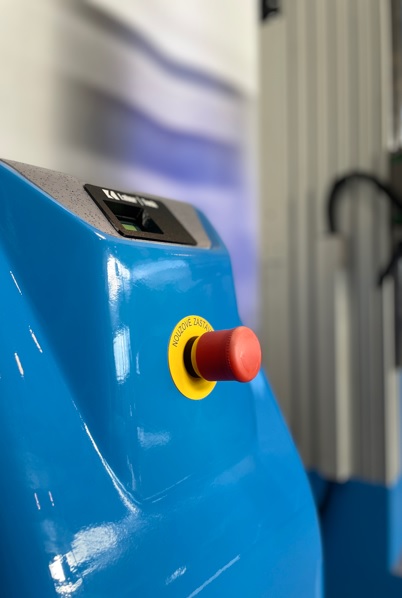

- Safety: Integrated STOP button for immediate shutdown if necessary

- Control expansion option: Connection of RMCi remote control or separate controller

- Color: RAL 5015 and RAL 1015

This unit is designed to ensure easy operation and high reliability when working with hydraulic wedge jaws, making it ideal for demanding industrial applications.

HAG 3 - SIMPLE-B - for jaws with side pressure - NEW DESIGN

The HAG 3 – SIMPLE hydraulic unit is specially designed for operating hydraulic jaws with side pressure. This unit features a new design, minimal noise and easy operation, making it the ideal choice for applications where efficiency and quiet operation are required.

Main specifications:

- Maximum pressure: motor power: 450 bar / 0.75kW

- Status indication: Basic information about the unit status displayed on the SIEMENS display

- Hydraulic hoses: Set of hoses up to 3 m long for connection to the jaws

- Pressure indicator: Manometric indicator for monitoring the current pressure in the system

- Safety: Integrated STOP button for immediate shutdown if necessary

- Control expansion option: Connection of RMCi remote control or separate controller

- Color: RAL 5015 and RAL 1015

This unit is designed to ensure easy operation and high reliability when working with hydraulic jaws with side pressure, making it ideal for demanding industrial applications.

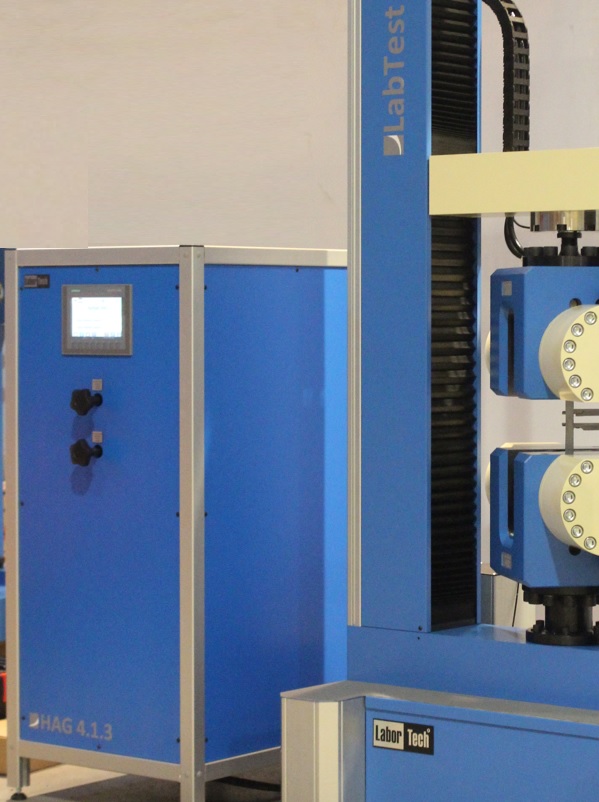

HAG 4.2.1 - for wedge jaws

The HAG 4 hybrid hydraulic power pack is designed specifically for operating wedge hydraulic jaws. This power pack is characterized by versatility, minimal noise and easy operation, making it the ideal choice for applications where efficiency and quiet operation are required.

Main specifications:

- Adjustable working pressure for each jaw separately: 20 to 160 bar

- Status indication: HALT 18 – comprehensive information on the status of the unit (pressure, temperature, filtration, oil level, tal in the jaws, etc.) displayed on the 7″ SIEMENS LCD display

- Drive: hybrid flow control with integrated AC converter from HALT 18

- Hydraulic hoses: set of hoses up to 3 m long for connection to the jaws

- Safety: integrated STOP button for immediate shutdown if necessary

- Control extension option: connection of RMCi remote control

- Color: RAL 5015

Add-on modules:

Electronic control of the pressing force in the jaws depending on the test force

Possibility of separate control of the jaws in different test areas

This unit is designed to ensure high reliability when working with hydraulic wedge jaws, which makes it ideal for demanding industrial applications.

HAG 4.2.3 - for jaws with side pressure

The HAG 4 hybrid hydraulic power pack is designed specifically for operating hydraulic jaws with side pressure. This power pack is characterized by versatility, minimal noise and easy operation, making it the ideal choice for applications where efficiency and quiet operation are required.

Main specifications:

Adjustable working pressure for each jaw separately: 60 to 450 bar

Status indication: HALT 18 – comprehensive information on the status of the unit (pressure, temperature, filtration, oil level, metal in the jaws, etc.) displayed on the 7″ SIEMENS LCD display

Drive: hybrid flow control with integrated AC converter from HALT 18

Hydraulic hoses: set of hoses up to 3 m long for connection to the jaws

Safety: integrated STOP button for immediate shutdown if necessary

Control extension option: connection of RMCi remote control

Color: RAL 5015

Add-on modules:

Electronic control of the pressing force in the jaws depending on the test force

Possibility of separate control of the jaws in different test areas

This unit is designed to ensure high reliability when working with hydraulic jaws with side pressure, which makes it ideal for demanding industrial applications.

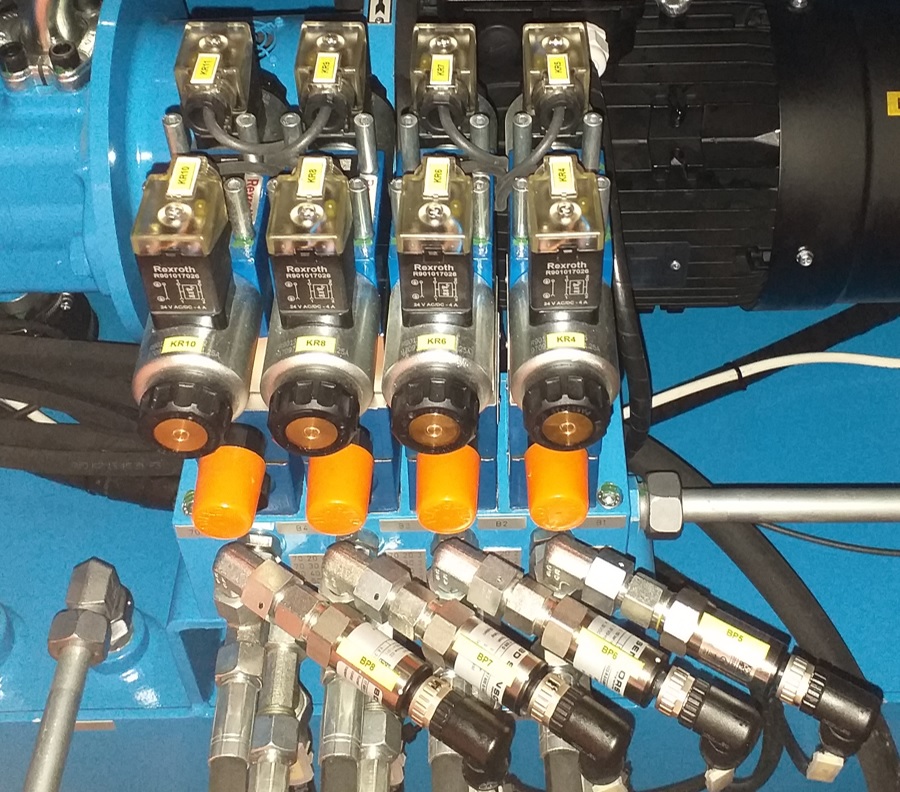

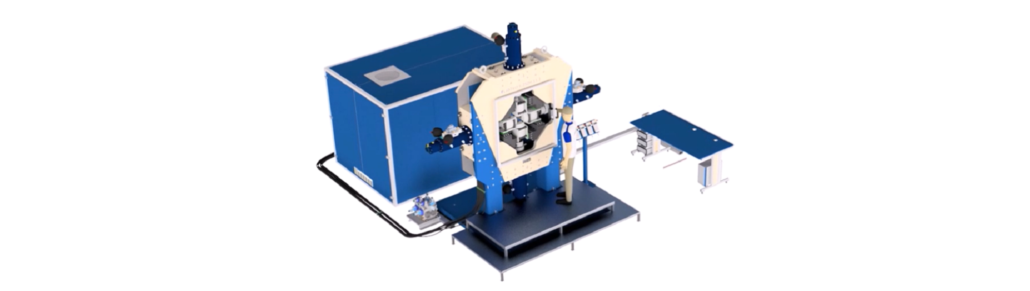

HAS hydraulic power units for static hydraulic machines

LABORTECH HAS: Quiet, powerful, smart – for flawless testing

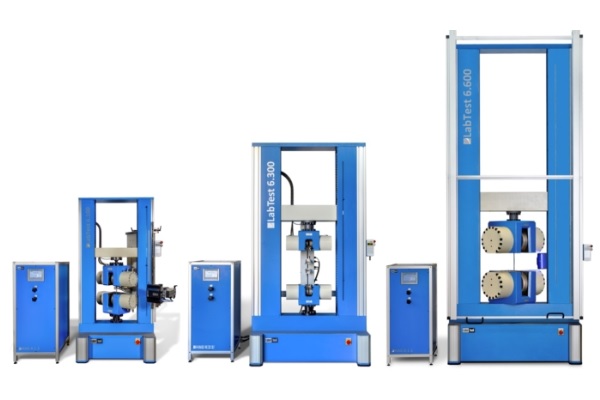

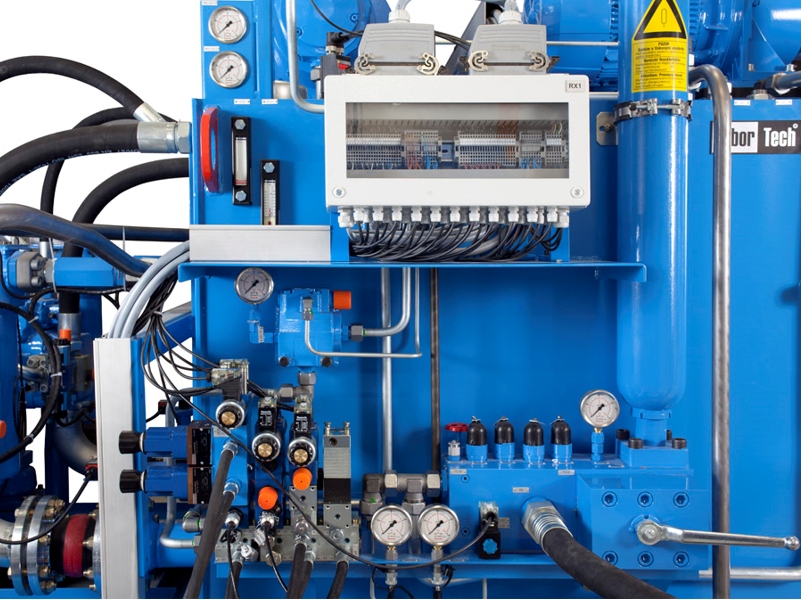

Compact hydraulic power packs HAS xx

Compact hydraulic power units of the HAS xx series are designed for controlling static servo-hydraulic testing machines. These units are manufactured in modifications 2, 4, 8 and 18 (Q=l/1 min). The units are characterized by versatility, minimal noise and easy operation, which makes them an ideal choice for applications where efficiency and quiet operation are required.

Main specifications:

- Max. working pressure: 350 bar

- Status indication: HALT 18 – comprehensive information on the status of the unit (pressure, temperature, filtration, oil level, metal in the jaws, etc.) displayed on the 7″ SIEMENS LCD display

- Drive: hybrid control of the AC motor by the inverter from HALT 18

- Outlets: double-sided hydraulic hose outlet

- Cooling: air cooling for long-term tests

- Oil collection pan with filling indication connected to HALT 18

- Electronics: modular cabinet for EDCi series electronics

- Safety: integrated STOP button for immediate shutdown if necessary

- Control extension option: connection of RMCi remote control

- Noise: integrated PAC noise protection cover

- Color: RAL 5015

Add-on modules:

Option for extension with a hydraulic jaw control system (160 to 450 bar)

Electronic control of the pressing force in the jaws depending on the test force

Option for independent jaw control in various test areas

This unit is designed to provide high reliability when working with H.1, H.2, H.4 or H.7 series hydraulic testing machines, making it ideal for demanding industrial applications.

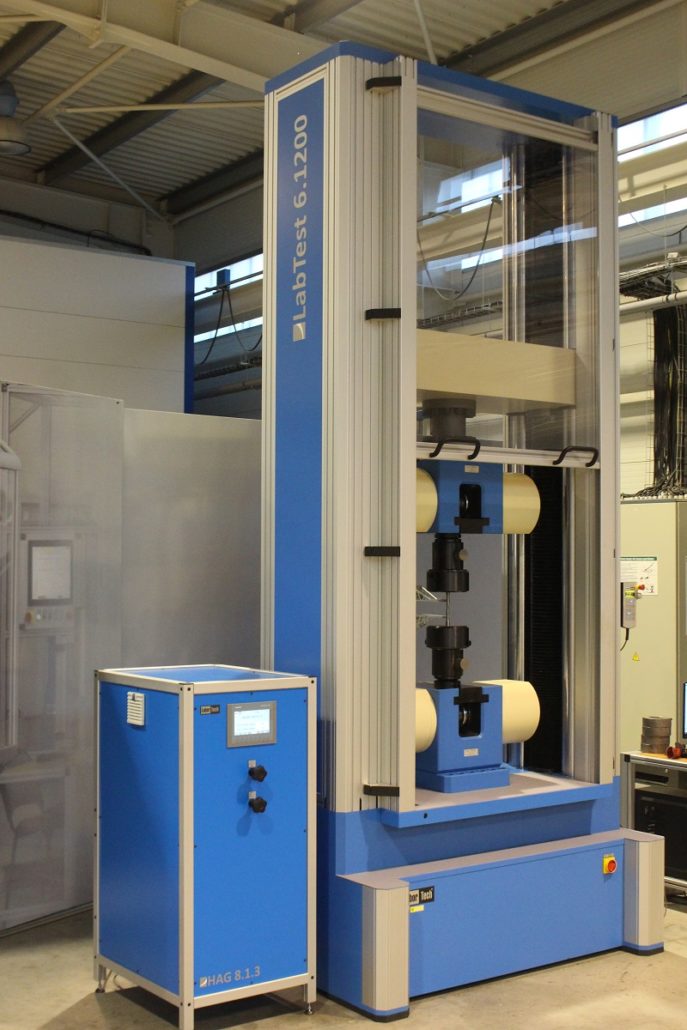

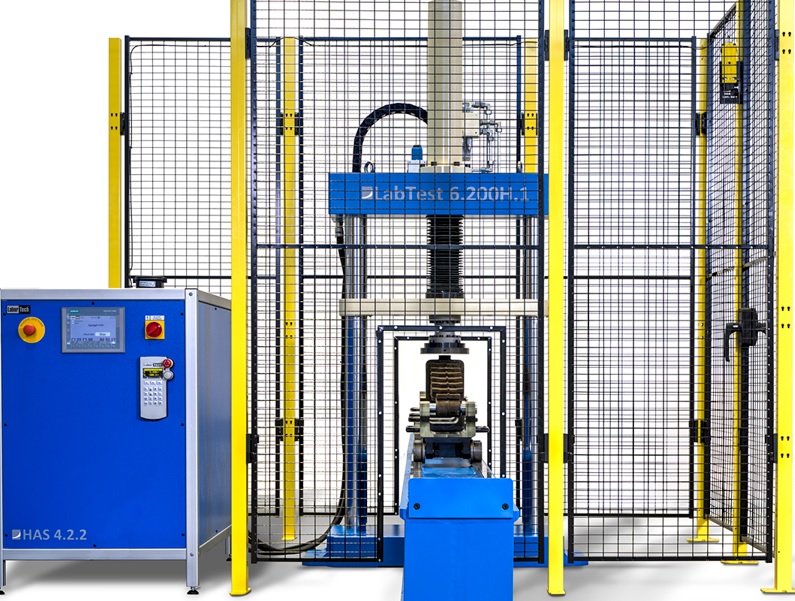

Hydraulic power units HAS xx for higher test speeds with protective cover

Compact hydraulic power units of the HAS xx series are designed for controlling static servo-hydraulic testing machines. These units are manufactured in modifications 40,63, 80 and 120 (Q=l/1 min). The units are characterized by versatility, minimal noise and easy operation, which makes them an ideal choice for applications where efficiency and quiet operation are required.

Main specifications:

- Max. working pressure: 350 bar

- Status indication: HALT 18 – comprehensive information on the status of the unit (pressure, temperature, filtration, oil level, metal in the jaws, etc.) displayed on the 7″ SIEMENS LCD display

- Drive: hybrid control of the AC motor by the inverter from HALT 18

- Outlets: double-sided hydraulic hose outlet

- Cooling: air cooling for long-term tests

- Oil collection pan with filling indication connected to HALT 18

- Electronics: modular cabinet for EDCi series electronics

- Safety: integrated STOP button for immediate shutdown if necessary

- Control extension option: connection of RMCi remote control

- Noise: integrated PAC noise protection cover

- Color: RAL 5015

Add-on modules:

Option for extension with a hydraulic jaw control system (160 to 450 bar)

Electronic control of the pressing force in the jaws depending on the test force

Option for independent jaw control in various test areas

This unit is designed to provide high reliability when working with H.1, H.2, H.4 or H.7 series hydraulic testing machines, making it ideal for demanding industrial applications.

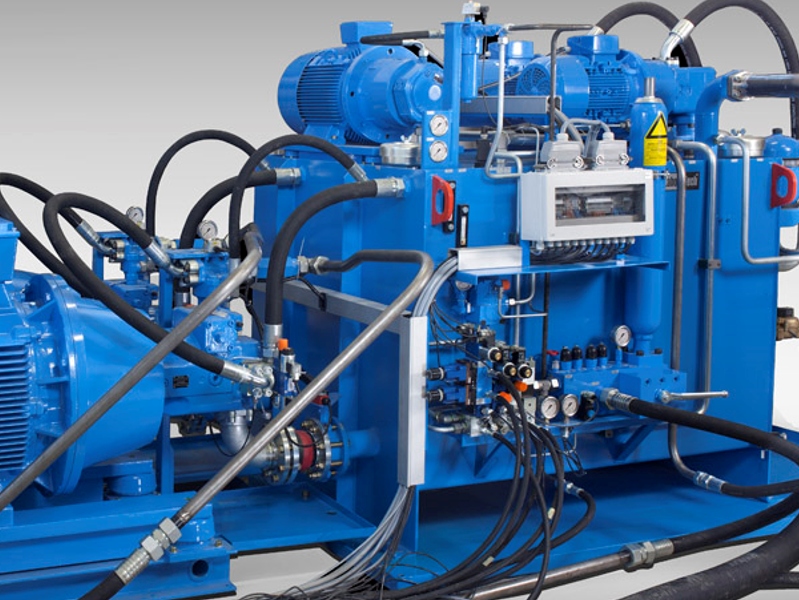

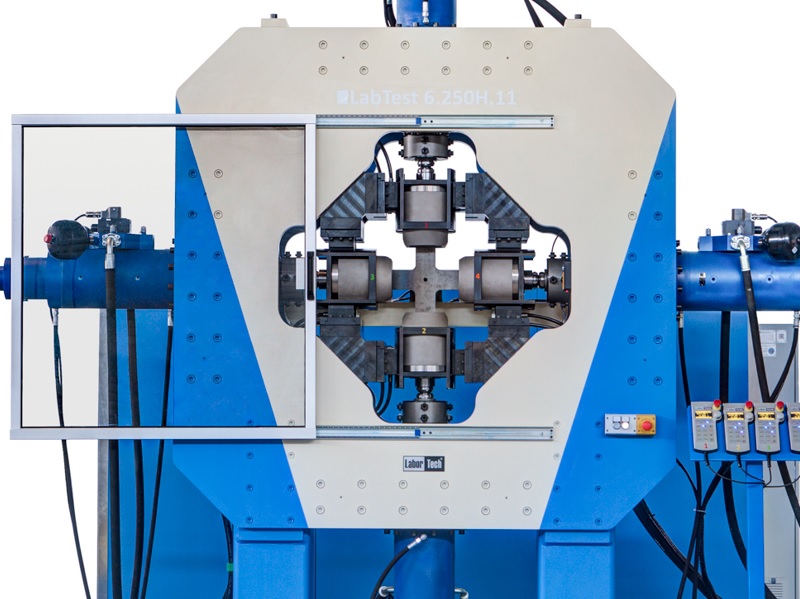

HAD hydraulic power packs for dynamic hydraulic machines

HAD – Power, precision and reliability for dynamic testing from LABORTECH!

HAD xxx hydraulic power packs for dynamic applications

The HAD series hydraulic units are designed to control dynamic servo hydraulic testing machines. These units are manufactured in modifications 12, 25, 40, 63, 80, 120, 165, 195 and 620 (Q=l/1 min). The units are characterized by versatility, minimal noise and simple operation, which makes them an ideal choice for applications where efficiency and quiet operation are required.

Main specifications:

- Max. working pressure: 210 or 280 bar

- Status indication: HALT 18 – comprehensive information on the status of the unit (pressure, temperature, filtration, oil level, metal in the jaws, etc.) displayed on the 7″ SIEMENS LCD display

- Drive: AC motor control from HALT 18

- Outlets: double-sided hydraulic hose outlet

- Cooling: air or water cooling for long-term tests

- Oil sump with filling indication connected to HALT 18

- Electronics: modular cabinet for EDCi series electronics

- Safety: integrated STOP button for immediate shutdown if necessary

- Control extension option: connection of RMCi remote control

- Noise: option to extend HA with PAC noise protection cover

- Color: RAL 5015

Add-on modules:

Option to extend with a hydraulic jaw control system (160 to 450 bar)

Electronic control of the pressing force in the jaws depending on the test force

Option independent jaw control in different test areas

This unit is designed to ensure high reliability when working with H.5, H.8, H.10 or H.11 series hydraulic testing machines, making it ideal for demanding industrial applications.

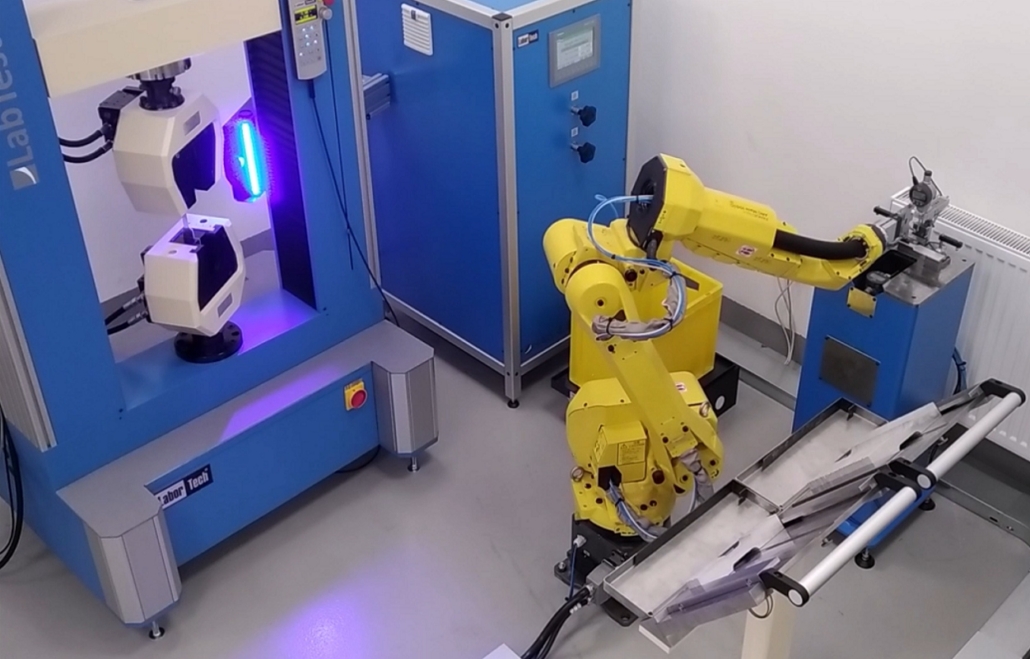

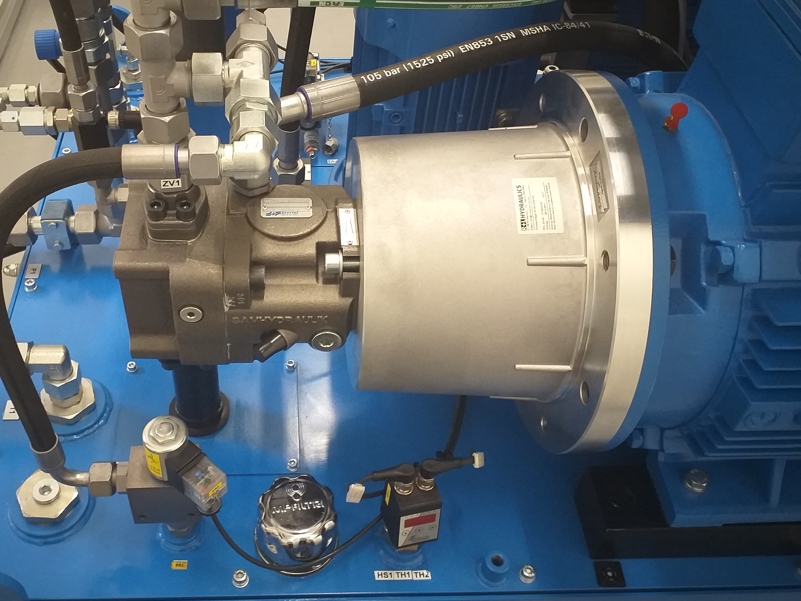

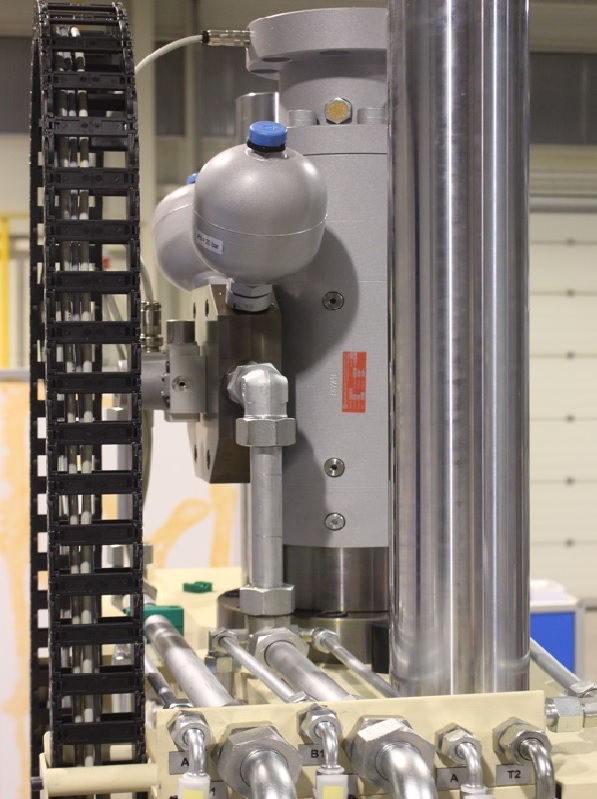

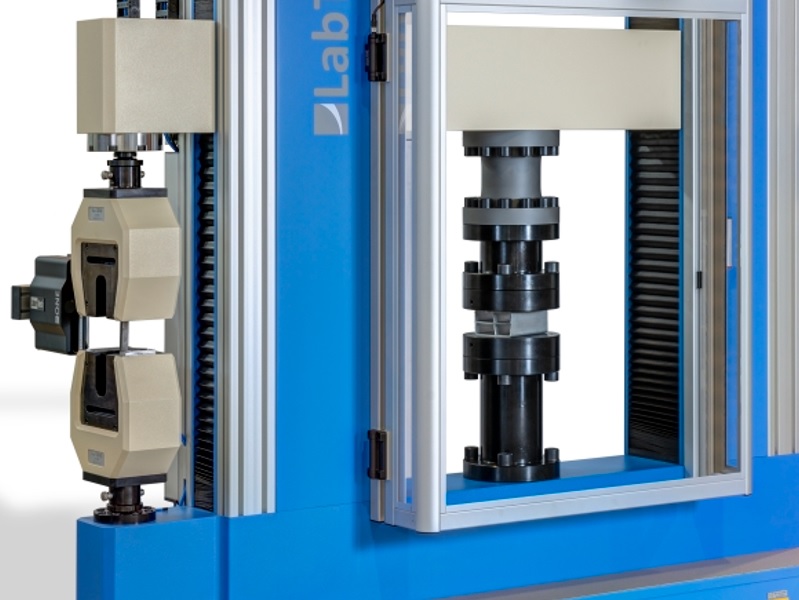

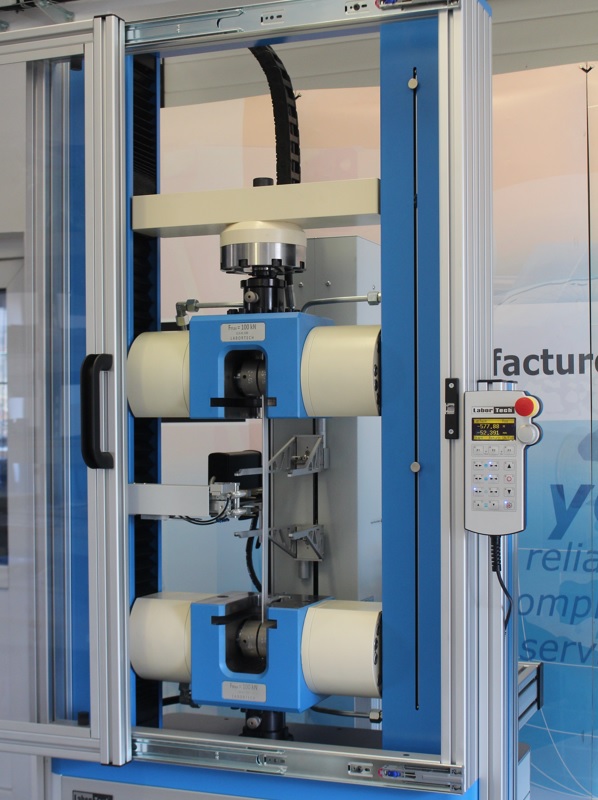

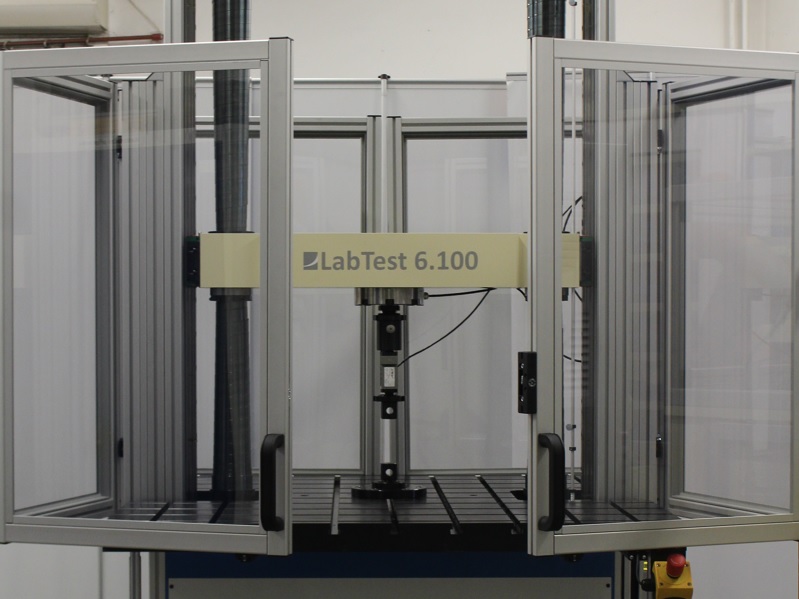

Servo hydraulic test cylinders for static and dynamic applications

LABORTECH servo hydraulic cylinders: Power and precision in every test

Dynamic servo-hydraulic cylinders LABORTECH

LABORTECH dynamic servo-hydraulic cylinders are a key part of dynamic fatigue testing systems, ensuring high accuracy and reliability when performing dynamic tests. Thanks to their advanced design and top-notch components, they meet even the most demanding requirements for testing materials and structures.

Main features and benefits:

- Standard working pressure: 210 or 280 bar

- Robust precision connection flange with shoulder for stable and secure mounting

- Special cylinder design with minimal friction ensuring maintenance-free and precise operation

- Integrated proportional or servo valve from renowned manufacturers MOOG or STAR

- Length sensor with SSI or LVDT technology for precise measurement of cylinder position

- Constant and precise pressure without pulsation in all circuits (P and T) thanks to accumulators

- Flexible connection to the hydraulic unit – up to 5 m with hydraulic hoses, over 5 m with fixed pipework

LABORTECH servo-hydraulic cylinders are designed for maximum efficiency, reliability and long service life, making them the ideal choice for demanding testing applications in industrial and scientific laboratories.

More information about dynamic and fatigue testing machines can be found here.

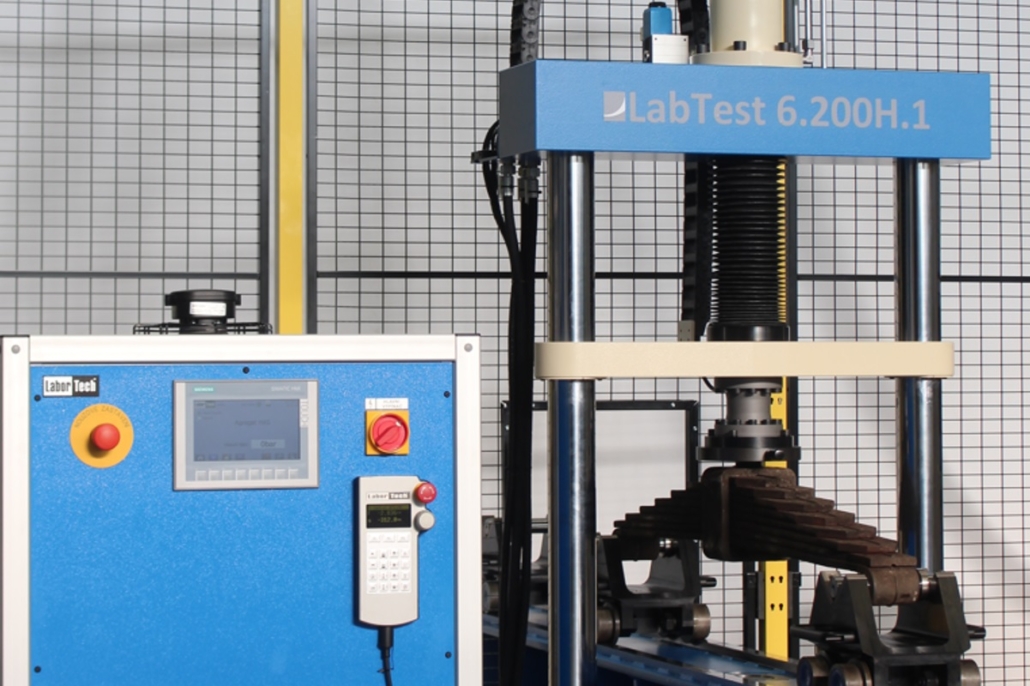

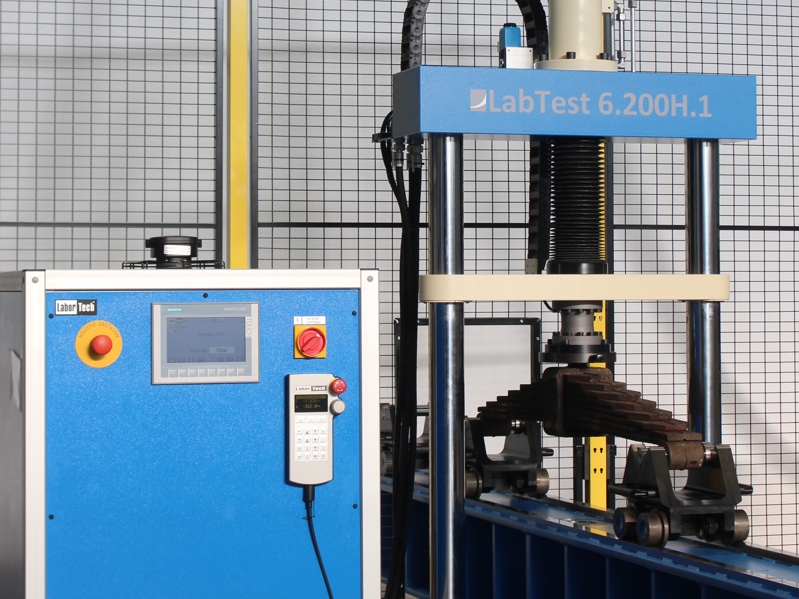

Static servo-hydraulic cylinders LABORTECH

LABORTECH static servo-hydraulic cylinders are a key part of static testing systems, where they ensure high accuracy and reliability when performing static tests. Thanks to their advanced design and top-notch components, they meet even the most demanding requirements for testing materials and structures.

Main features and benefits:

- Standard working pressure: up to 450 bar

- Robust precise connection flange with shoulder for stable and secure fastening

- Special cylinder design with minimal friction ensuring maintenance-free and precise operation

- Integrated proportional or servo valve from renowned manufacturers MOOG or STAR

- Length sensor with SSI technology for precise measurement of cylinder position

- Flexible connection to the hydraulic unit – up to 5 m hydraulic hoses

LABORTECH servo-hydraulic cylinders are designed for maximum efficiency, reliability and long service life, which makes them the ideal choice for demanding testing applications in industrial and scientific laboratories.

More information about static testing machines can be found here.

Contact

LABORTECH s.r.o. , Rolnická 1534/130a, 747 05 Opava, Czech Republic

Research & Development

Reducing energy intensity We increase your productivity Development and implementation

News & Events