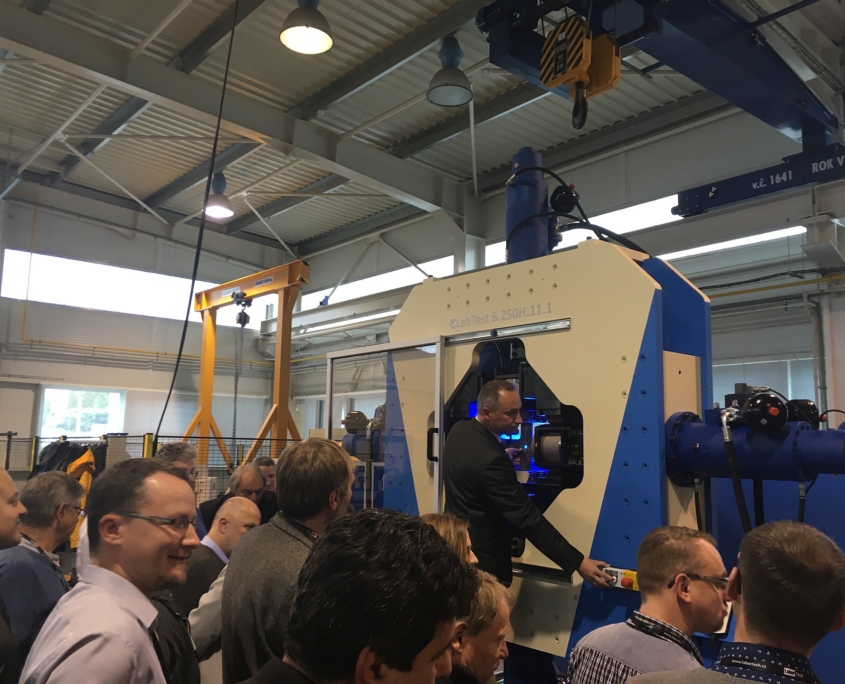

As part of our regularly held promotion events, we introduced to our customers a unique Servo-hydraulic dynamic Biaxial testing machine for multi-axis loading.

Tuesday 5.11. one of our regularly held promotion events took place in the showroom of our production hall, but this event was unique not only by the number of machines that visitors could see, but by its programm. We introduced to our guests projects that were innovative in the field of material engineering with their approach and method of application. We wanted to introduce projects that helped our customers, whether to reduce the total cost of the production process itself, increase production potential to raise potential profit or reduce the overall energy consumption of machines, thereby reducing the environmental impact.

We are also very pleased that during the presentations our customers themselves told us and shared with our colleagues the positive experience with the acquisition of our testing machines, which brought them a quick financial return, only a few months after the purchase of the equipment. We perceive these findings as a huge success.

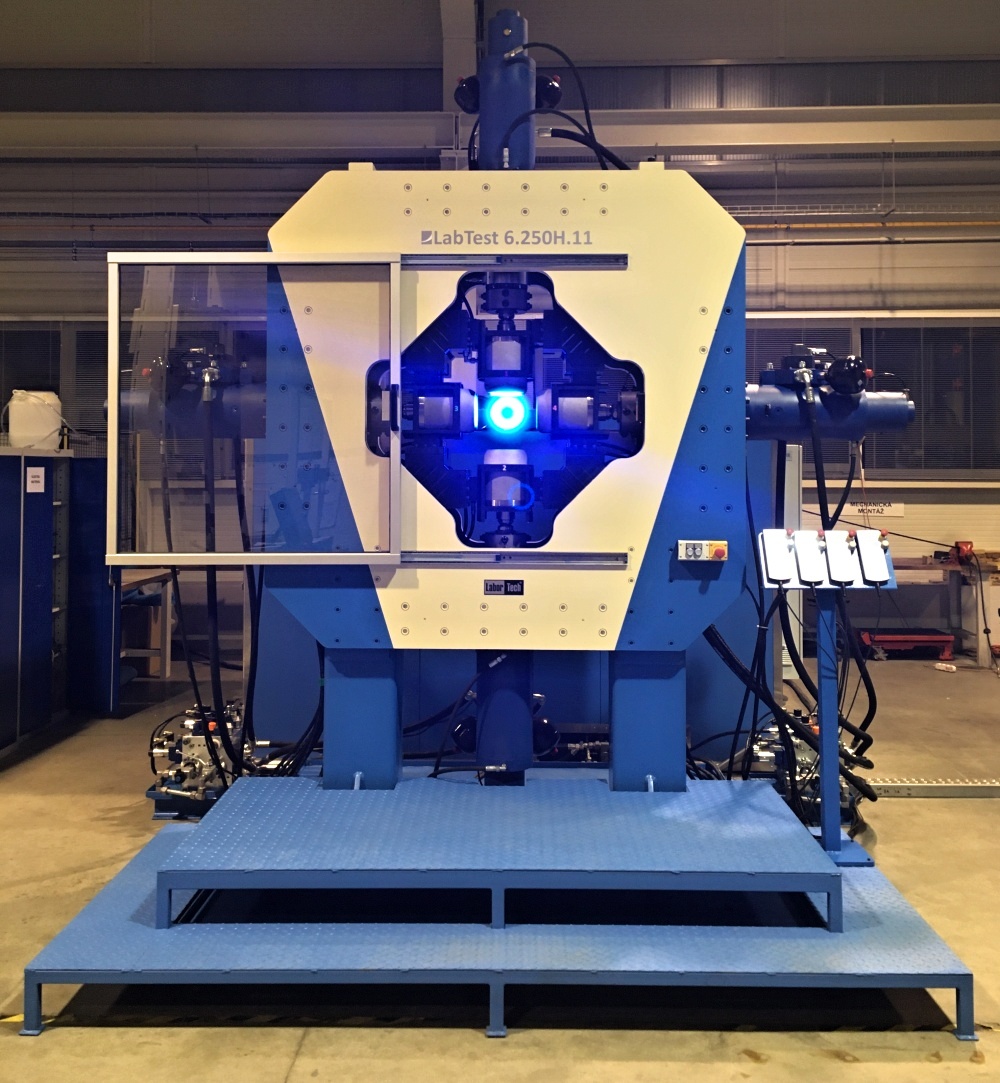

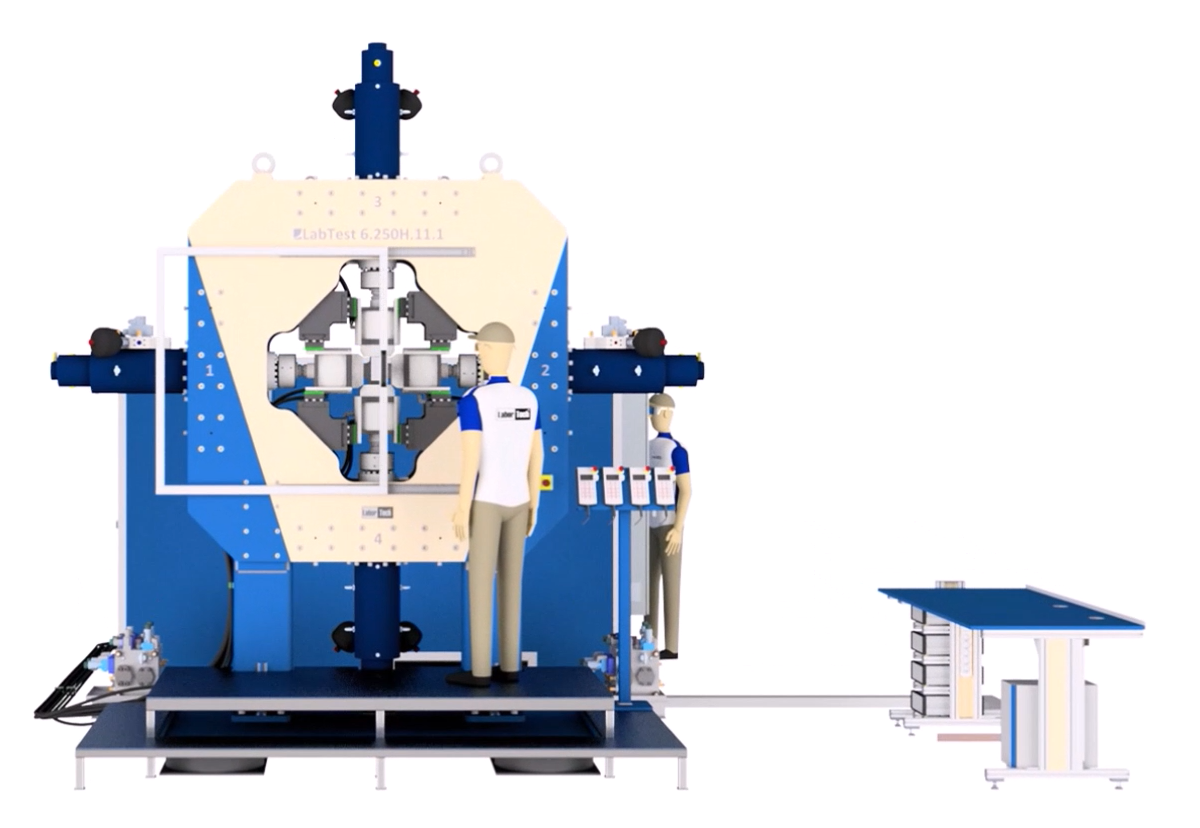

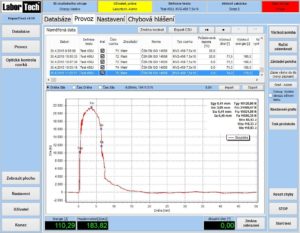

The highlight of the event was the introduction of a Servo-hydraulic dynamic biaxial testing machine with official name LabTest 6.250H.11, which we have not yet produced in the Czech Republic. This machine was specially developed for Moscow University for multi-axis, low and high cycle loading of composites and materials for the aerospace industry.

LabTest 6.250H.11

We would like to thank all participants of the event and we look forward to seeing you again at our next promotion events

TEAM LABORTECH

or deformation

or deformation