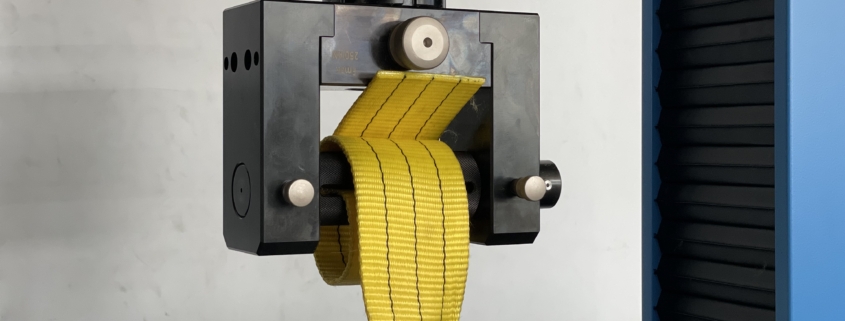

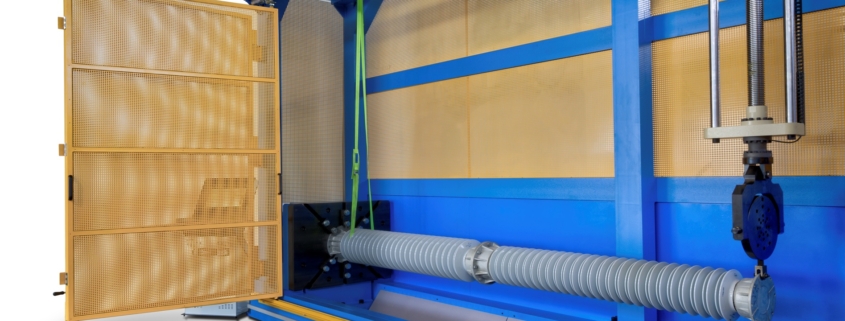

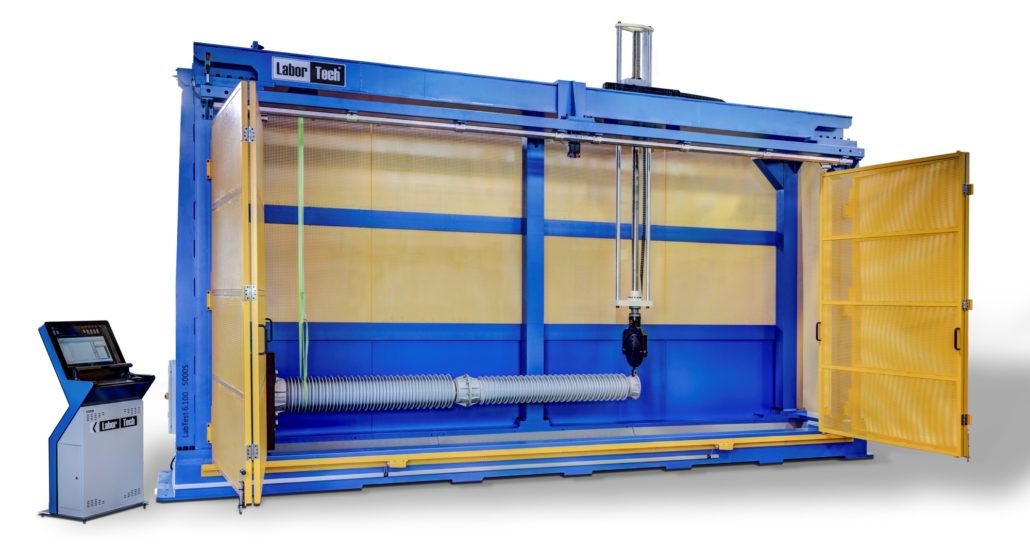

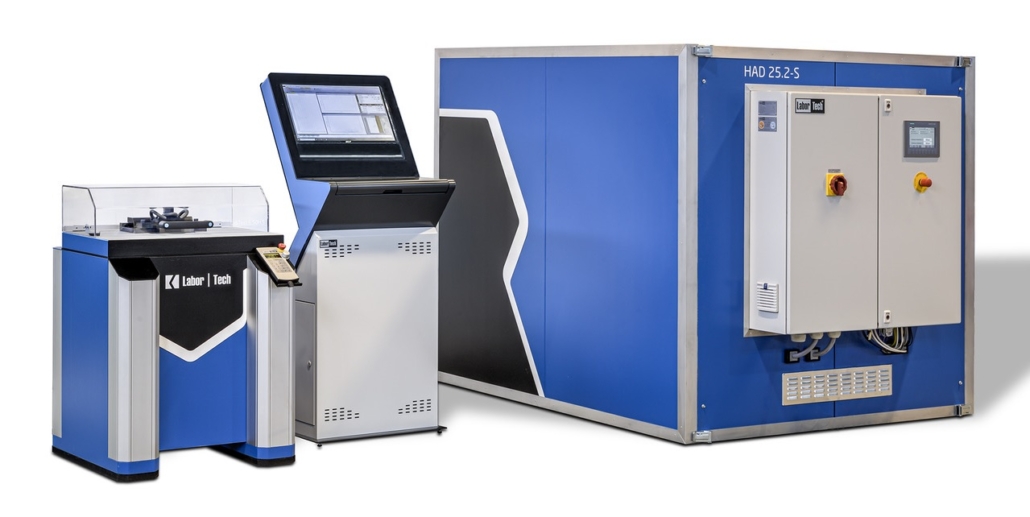

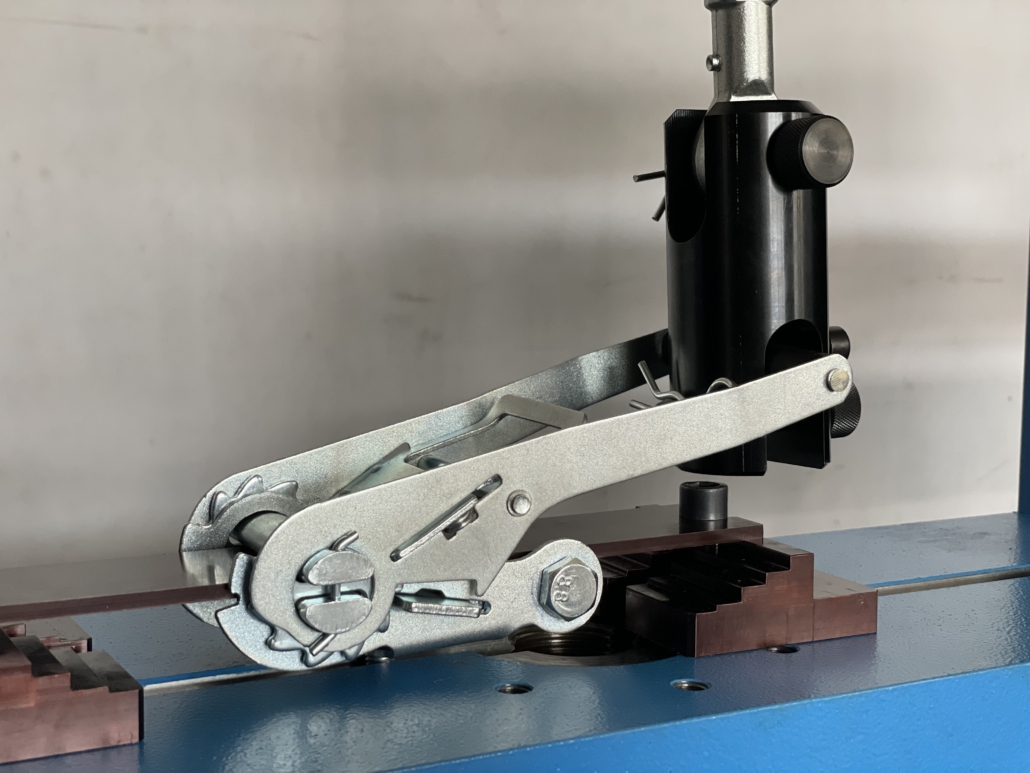

Cargo straps are critical components for ensuring the safe transportation of goods, whether by road, rail, or air. Their reliability and strength are essential to keep cargo securely in place, even under challenging conditions. This is why the testing of fastening straps is so important, and LABORTECH is a leader in this field thanks to its LABTEST series of testing machines, which can be used to test straps and fastening devices according to the following standards: EN 12195-2, FMCSA 49 CFR 393.102 (USA) , DIN 60060, AS/NZS 4380:2001 (Australian Standard) or CSA D270-16 (Canadian Standard).

LABTEST Testing Machines: Guarantee of Quality and Safety

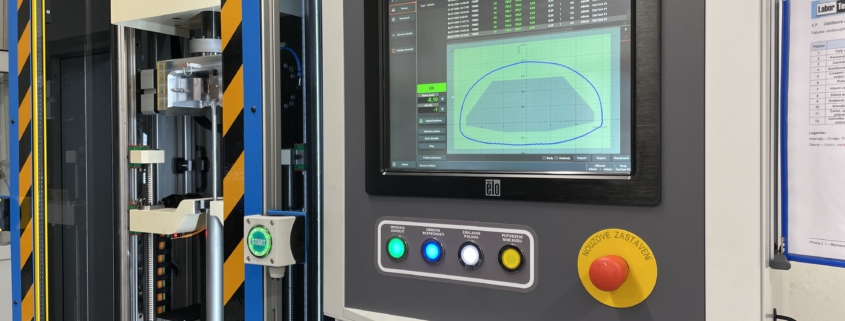

LABTEST testing machines from LABORTECH are designed to deliver precise and reliable results when testing cargo straps. These machines can perform various types of tests that simulate the real conditions to which the straps are subjected during transportation.

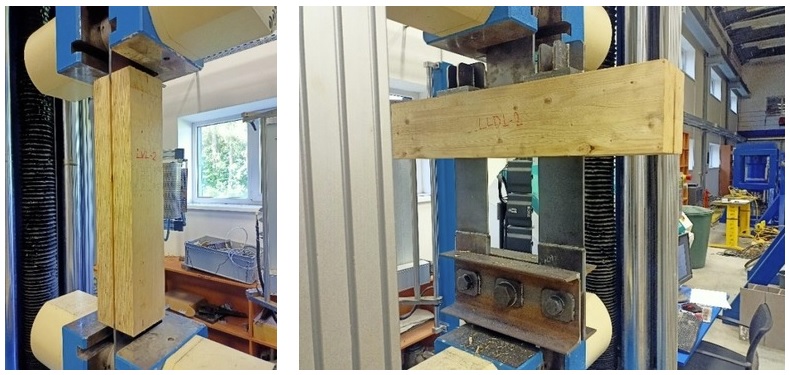

Tensile Tests: Tensile tests measure the maximum strength of the straps and verify if they can withstand the load specified by the manufacturer.

Fatigue Tests: These tests simulate repeated use of the straps, helping to identify their long-term durability and lifespan.

Dynamic Tests: By simulating sudden impacts and vibrations that may occur during transportation, these tests assess how the straps behave in extreme situations.

Safety First

In the field of cargo transportation, there is no room for compromise when it comes to safety. Cargo straps must not only meet strict standards and regulations but also endure demanding conditions in practice. LABORTECH recognizes that safety comes first, which is why its LABTEST machines provide thorough and reliable testing.

Every testing process is designed to identify even the slightest weaknesses in the straps, allowing for early detection and correction before they reach the market. In this way, LABORTECH ensures that the cargo straps used in transportation are safe, reliable, and capable of protecting the cargo under any circumstances.

LABORTECH: Your Partner for Safety and Quality

The LABTEST machines are the result of years of experience and continuous innovation, ensuring that our products meet the highest standards of quality. If you’re looking for a reliable solution for testing cargo straps, LABTEST machines from LABORTECH are the right choice. Our machines will help you ensure that your products meet all safety standards and protect your cargo even in the most demanding conditions. Safety is our top priority, just as it is yours.

TEAM LABORTECH