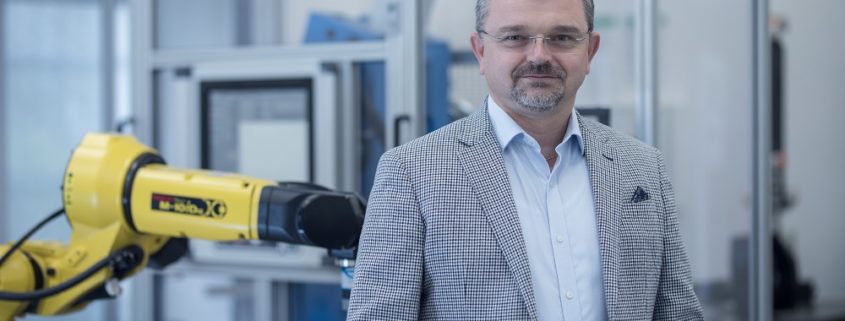

As of September 1, 2020, Ing. Libor Klimpar became the COO of LABORTECH s.r.o., who will continue to be responsible for the operation directing and management of the company, strategy-making, policy making to meet the stated goals. Our successful, dynamically developing team will be strengthened by experience from the international environment of engineering companies, where he worked in the areas of business, service, maintenance, assembly and project management.

Ing. Libor Klimpar – COO

Interview with the new CEO of LABORTECH s. r. o.

Mr. Klimpar, what are your first impressions?

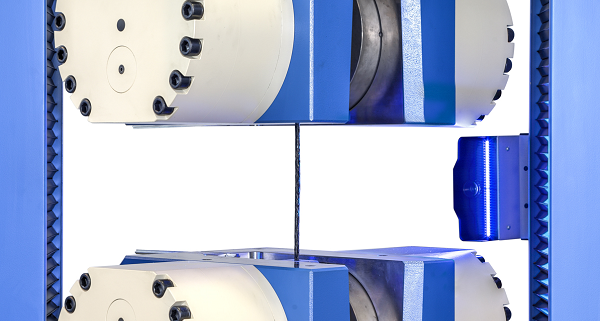

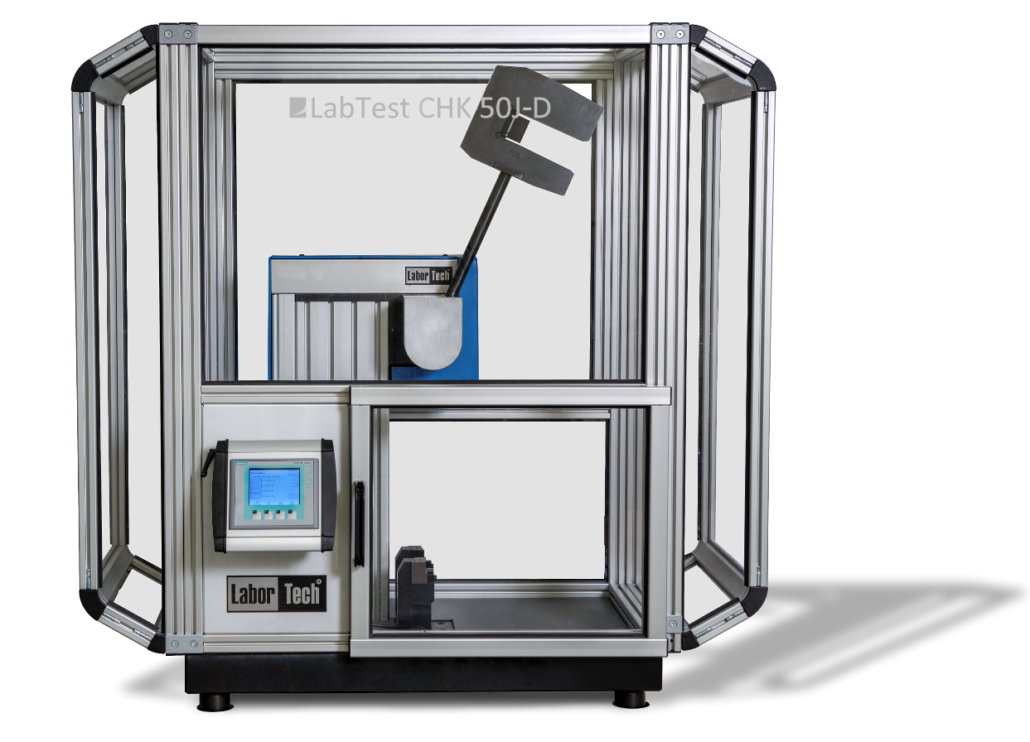

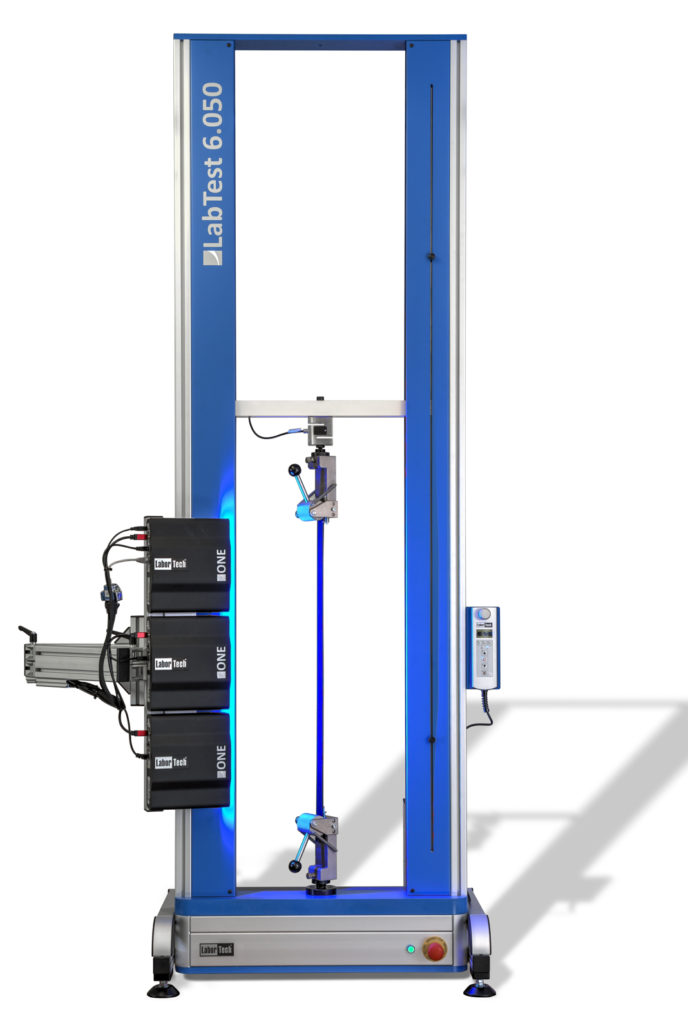

It is especially an honor for me to be able to work for such a highly developed technology company and participate in its further development. Thanks to the successful development of a unique technically biaxial machine, we are one of the three world leaders in the test machine market. I feel that mutual openness, cooperation and flexibility are important for the LABORTECH team. Everyone contributes to our development with their work and has a desire to constantly improve and find new solutions.

How does the current situation affect the stability of company?

We are a strong, healthy Czech family company, with a comprehensive portfolio of products, with our own development. We also have a wide range of services.

Thanks to the foresight of Mr. Dušek, owner and company director, we have invested to the promoting of our company, which brings us fruit in the form of orders from around the world and more than 20 industries.

I have to highlight and greatly appreciate the work of foreign partners, supported by our sales team. They successfully sell our products and they support our growth even in today’s difficult times.

Where do you see the future of LABORTECH?

Everywhere in the world. I believe, and our results suggest that even a small Czech company can conquer the world. I believe in our future, because “Every small detail matters” is, by the way, the new motto of our company and it is precisely the details in which we try to excel.

And word at the end?

Thank you and I wish all of us, our colleagues, partners, customers and their families, to overcome the difficulties of today together and in good health.

LABORTECH TEAM