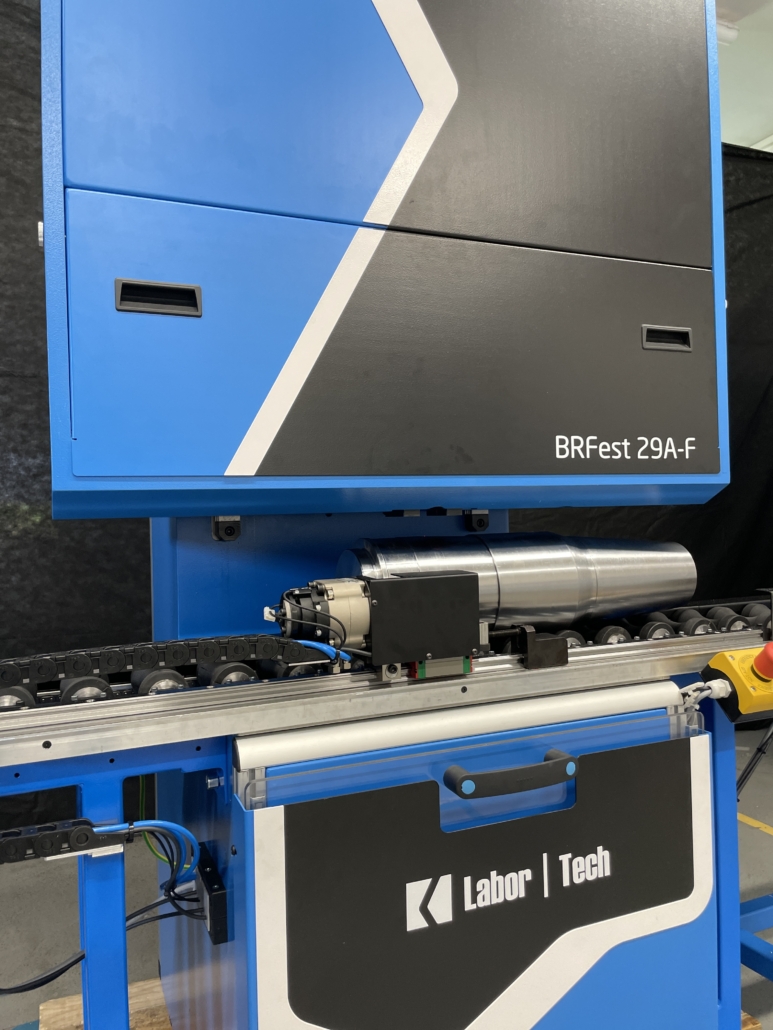

AQUATest 642 represents a modern second generation of equipment for the Jominy end-quench hardenability test of steel, developed in compliance with ČSN EN ISO 642 – Steel: End-quench test for hardenability, including its international equivalents ISO 642, ASTM A255 and JIS G 0561, which define methods for determining steel hardenability by end-quenching. The device builds on proven LABORTECH solutions and offers a higher level of automation, precision and safety. The modern EDICE 30 design is complemented by a 7″ LCD touchscreen, enabling intuitive operation and clear monitoring of all operating and diagnostic functions.

The system features central water flow control combined with a controlled pump, ensuring a stable, standard-defined flow rate essential for accurate and repeatable Jominy testing. Integrated temperature monitoring continuously controls the inlet medium temperature and minimizes deviations affecting test accuracy. The device can be optionally extended with a water heating system up to 60 °C, always supplied with an integrated safety protective cover to eliminate the risk of scalding. AQUATest 642 is available in versions for both European and American markets and is delivered with a Declaration of Conformity and complete technical documentation.

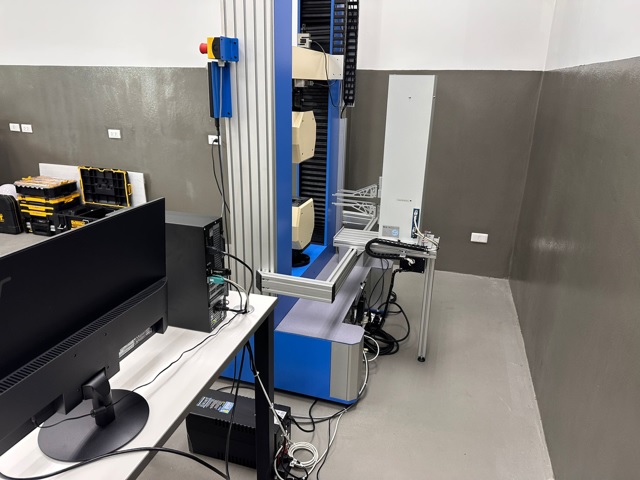

Thanks to its capabilities, it is intended for steelmaking and metallurgical plants, heat treatment facilities, research institutes and university laboratories where precise, fast and repeatable evaluation of steel hardenability according to Jominy is required.

TEAM LABORTECH