LABORTECH introduces the new generation of hydraulic testing presses H.4 – LabTest 7.xxxH.4, combining cutting-edge technology, maximum accuracy and cost-efficient operation.

At the heart of the new series are the modern HAS NEO, hydraulic power units, characterized by economic operation, minimal noise and compact design. They provide users with a powerful, reliable and energy-efficient solution ready for everyday use in both laboratories and industrial environments.

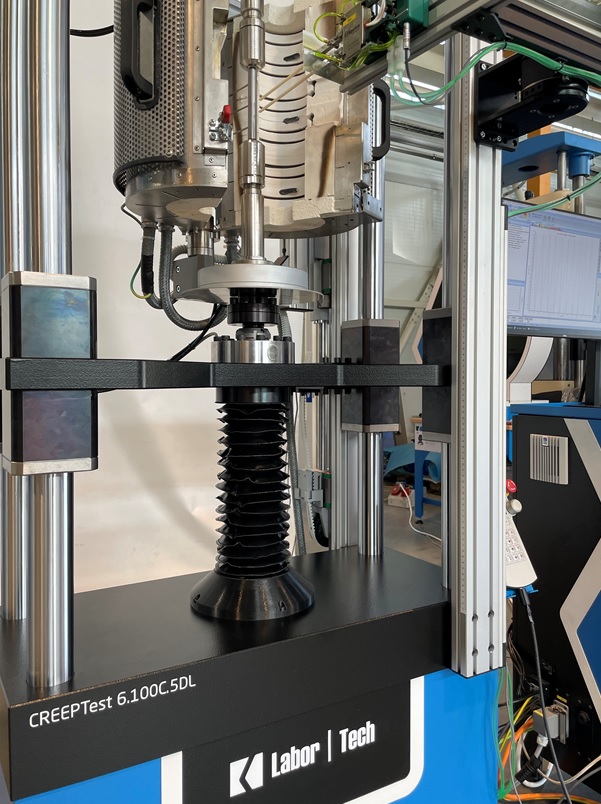

The robust four-column frame delivers maximum stiffness and accuracy, which is essential for compression testing. The unique side test area for bending, equipped with a double-acting cylinder and an electronic load cell insensitive to side forces, further expands the testing possibilities without compromising accuracy.

Safety always comes first. That is why the LabTest 7.xxxH.4 presses are equipped with advanced safety features such as test area shielding, safety locks and emergency STOP systems, ensuring maximum protection for both operators and the equipment itself.

The new LabTest 7.xxxH.4 presses fully comply with the stringent requirements of ČSN EN ISO 7500-1 and EN 12390-4, guaranteeing high-quality and repeatable test results even in the most demanding applications.

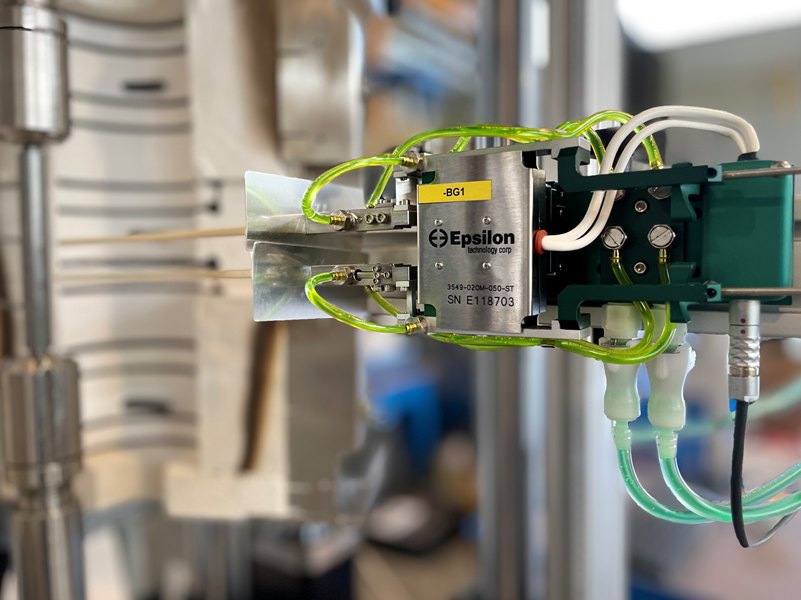

For maximum flexibility, the machine can be operated directly from the measuring and control electronics or via the advanced Test & Motion (T and M) software. This allows for automated testing with speed control, deformation control and E-modulus measurement, delivering maximum efficiency and user comfort.

LABORTECH TEAM