Contact

The X-RUNNER robotic systems from LABORTECH allow the handling of standard standardized samples as well as entire products with standard testing systems. The modular system for robotic testing systems offers the possibility of performing the required tests efficiently and reproducibly. Customer solutions can be individually assembled from standardized components.

X-RUNNER-T FOR TENSILE TESTING OF SPECIMENS

Automated tensile testing of metal and plastic samples according to EN ISO 6892-1 and EN ISO 527-1

Testing of metallic or plastic materials – automated tensile testing at ambient temperature, definition of properties that can be determined from this test. The test consists of deforming the test specimen under tensile loading, usually to fracture, in order to determine one or more mechanical properties defined in the standard. The standard specifies the conditions necessary for the correct performance of the test, in particular the setting and selection of defined test speeds expressed as the rate of increase of contractile stress or the strain rate with a clear preference for controlling the strain rate.

AZS.1 – ROBOTIC WORKSTATION X-RUNNER-6.100 FOR TENSILE TESTS OF FLAT SAMPLES

Description:

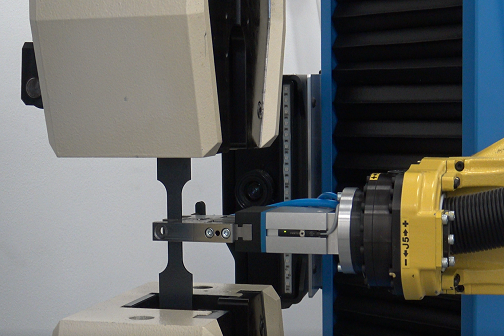

Automated robotic testing system X-RUNNER-6.100 designed for precise and fast handling of flat samples in conjunction with electromechanical testing machines LabTest E.3 series. This robotic system is produced in several modifications and is designed for automatic testing of flat samples placed on top of each other. A separate insert in the magazine is designed for each Lc dimension.

Characteristics:

Automatically distinguishes different types of samples, max. test force 100kN

Contact system for measuring sample dimensions – MME 10 – max. test sample weight up to 1kg

ONE 1 camera system for measuring relative elongation and contraction.

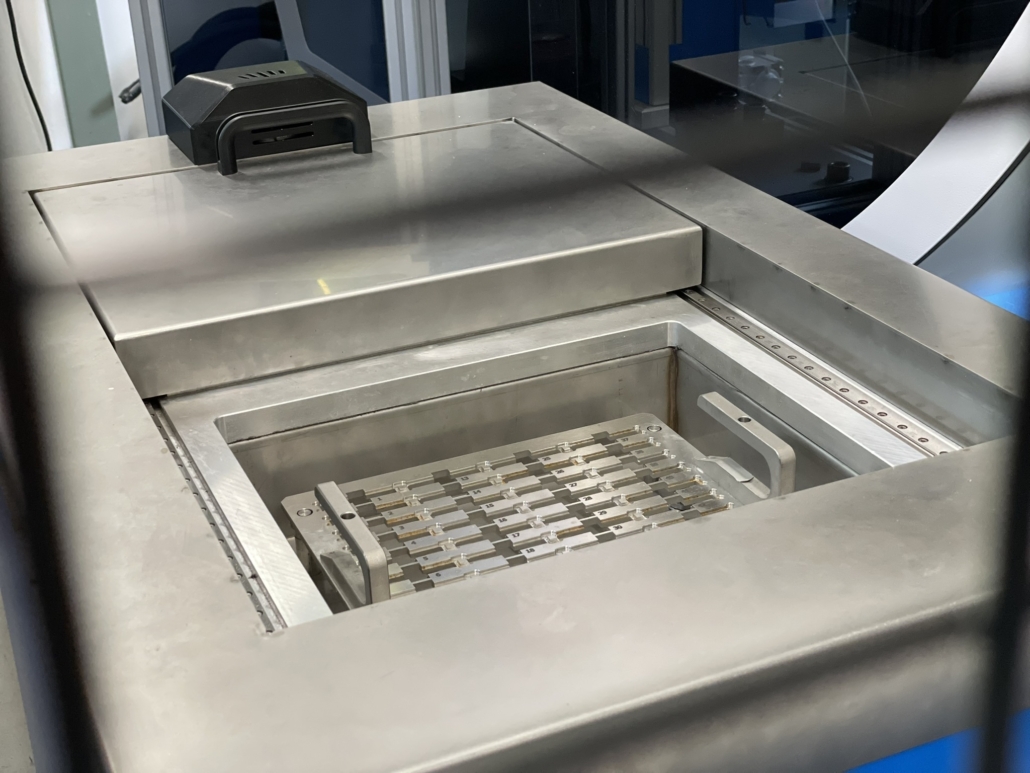

Tray system designed for 2×60 flat samples up to 5 mm thick. Samples are taken from the tray pneumatically.

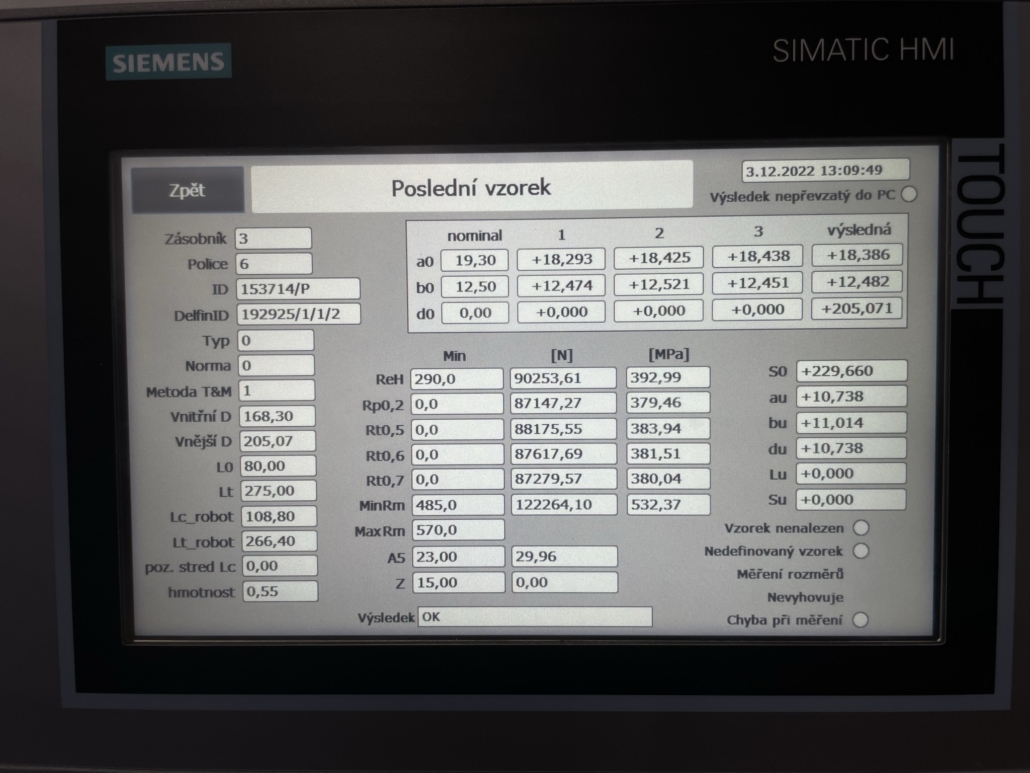

X RUNNER control system – SIEMENS Simatic S7 1500 incl. LCD.

Application – Standards:

Automated testing of standardized samples in accordance with EN ISO 6892-1 or EN ISO 527-1.

Expandable accessories:

Different types of containers depending on the type of samples, sample dimension measuring devices, marking and identification devices, VIDEO Extensometer, various types of clamping jaws and fixtures, special robotic grippers, boxes for collecting broken samples, extended container systems..

AZS.1 – ROBOTIC WORKSTATION X-RUNNER-6.600 FOR TENSILE TESTS OF VARIOUS SAMPLES

Description:

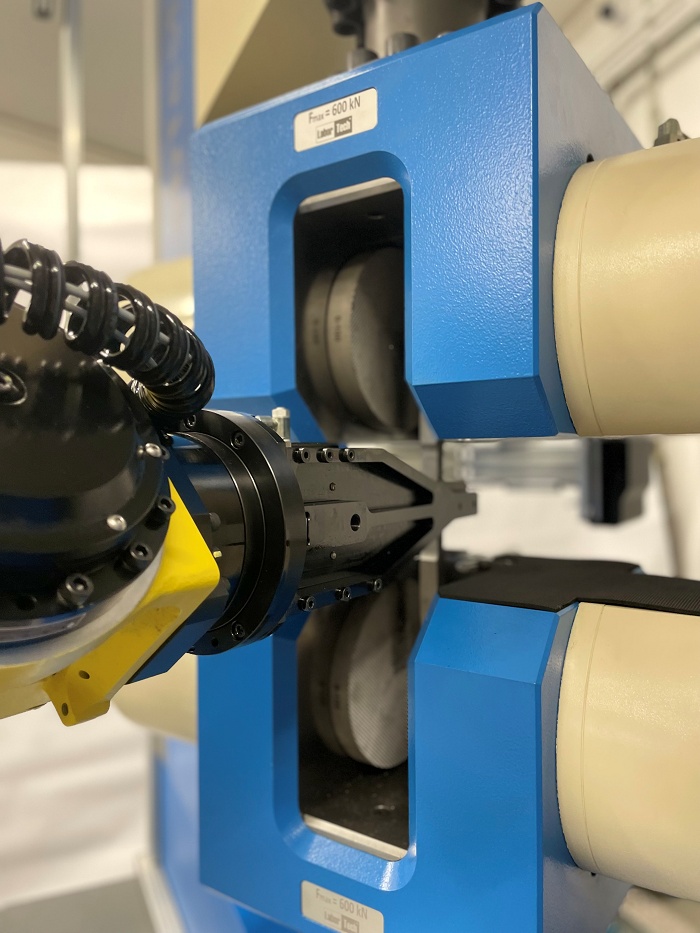

Automated robotic testing system X-RUNNER-6.600 designed for precise and fast sample handling in conjunction with electromechanical or hydraulic testing machines LabTest E series and H series. This robotic system is produced in several modifications and is designed for automatic testing of round, flat and segmented samples with various Lc dimensions.

Characteristics:

Automatically distinguishes different types of samples, max. test force 600kN

Non-contact system for measuring sample dimensions – LME 50 – flat, segmented and round up to 20kg

DOUBLE ONE 1 camera systems for measuring relative elongation and contraction.

Tray system designed for 112 samples without difference in shape and size up to 50 mm thickness

X RUNNER control system – SIEMENS Simatic S7 1500 incl. LCD.

Application – Standards:

Automated testing of standardized samples in accordance with EN ISO 6892-1.

Expandable accessories:

Different types of containers depending on the type of samples, sample dimension measuring devices, marking and identification devices, VIDEO Extensometer, various types of clamping jaws and fixtures, special robotic grippers, boxes for collecting broken samples, extended container systems..

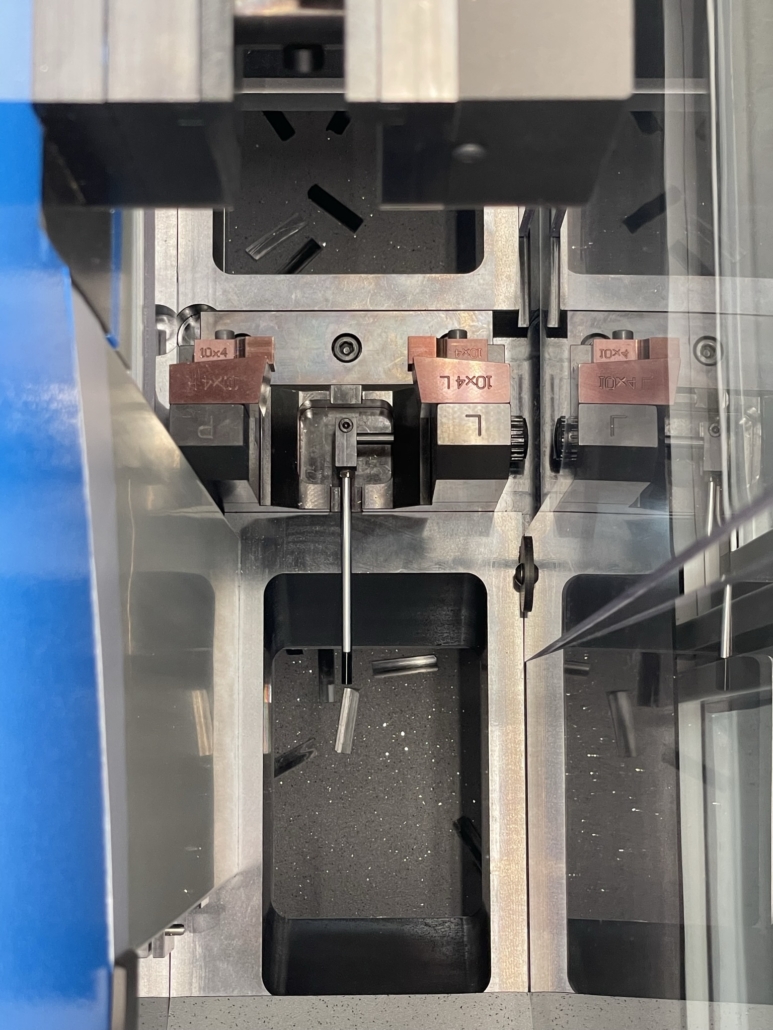

X-RUNNER-CH FOR IMPACT TESTS

Automated impact testing of metal and plastic samples according to EN ISO 148-1

Bending impact test – which consists of breaking a test specimen with a notch with a single impact of a pendulum hammer under specified conditions. The notch in the test specimen has a given geometry and is located in the middle between two supports on the opposite side to the impact point during the test. The test determines the energy absorbed during the impact test. In addition, the transverse extension and the percentage of ductile fracture are determined, in accordance with the customer’s requirements.

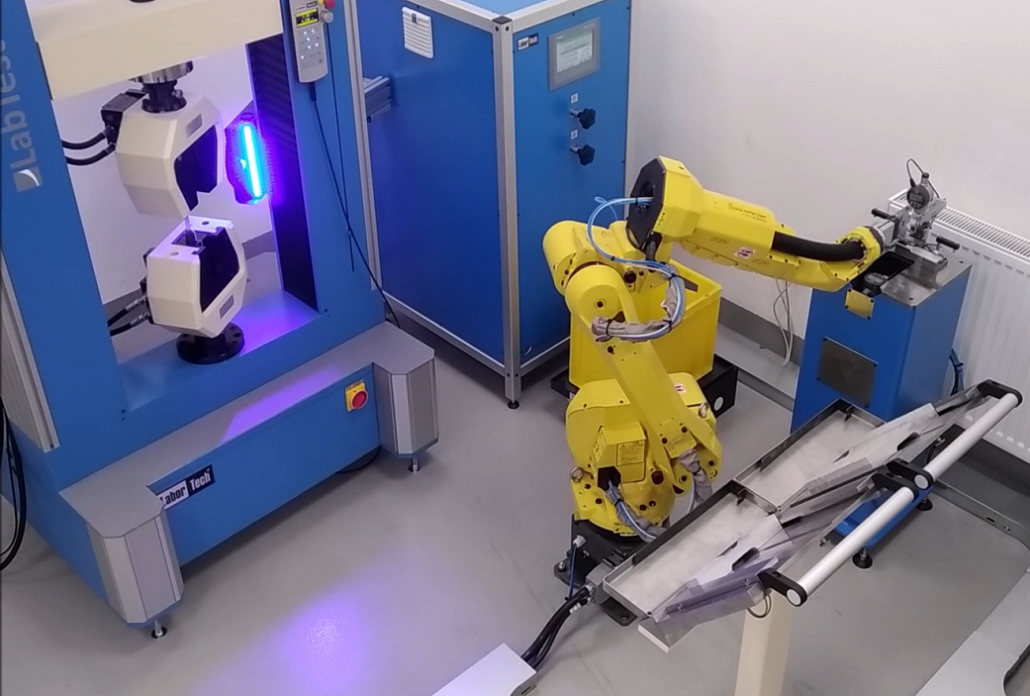

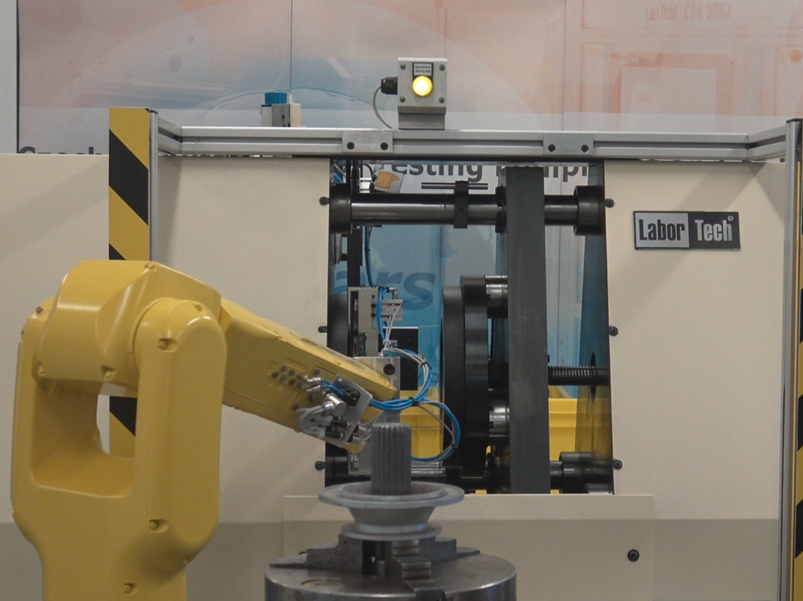

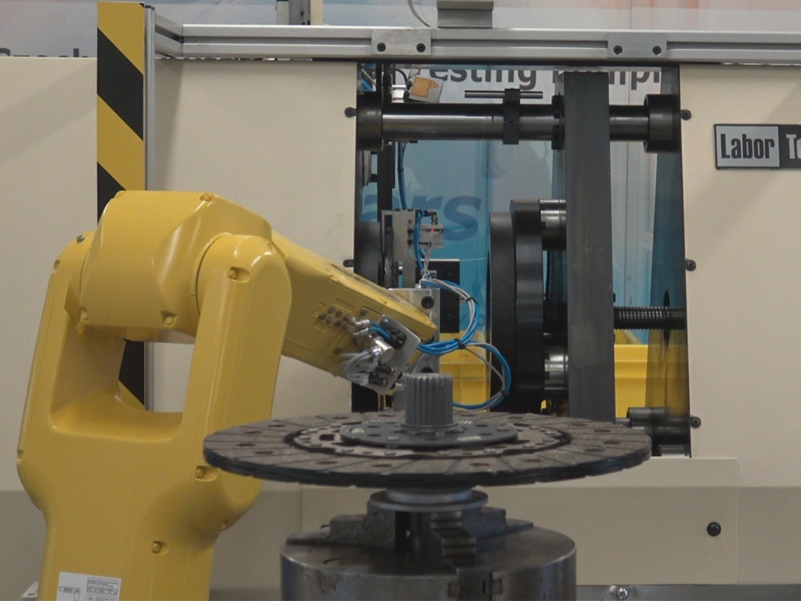

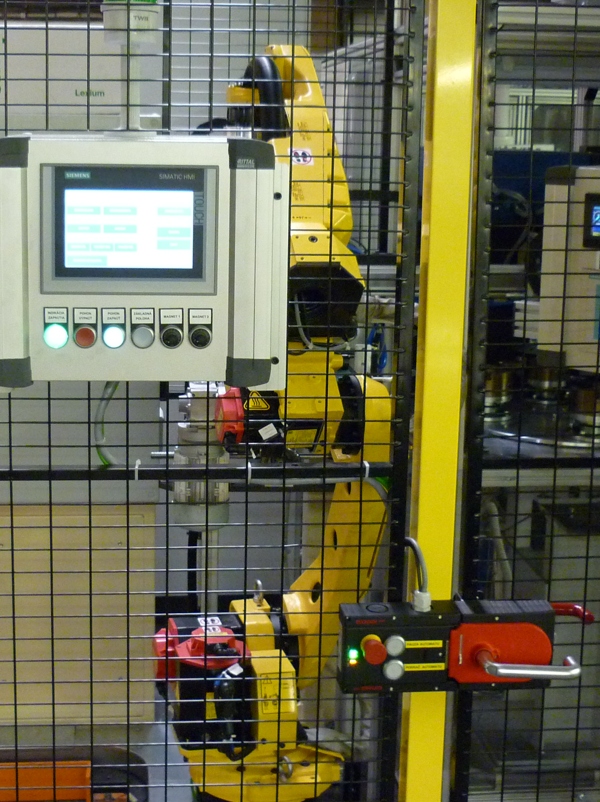

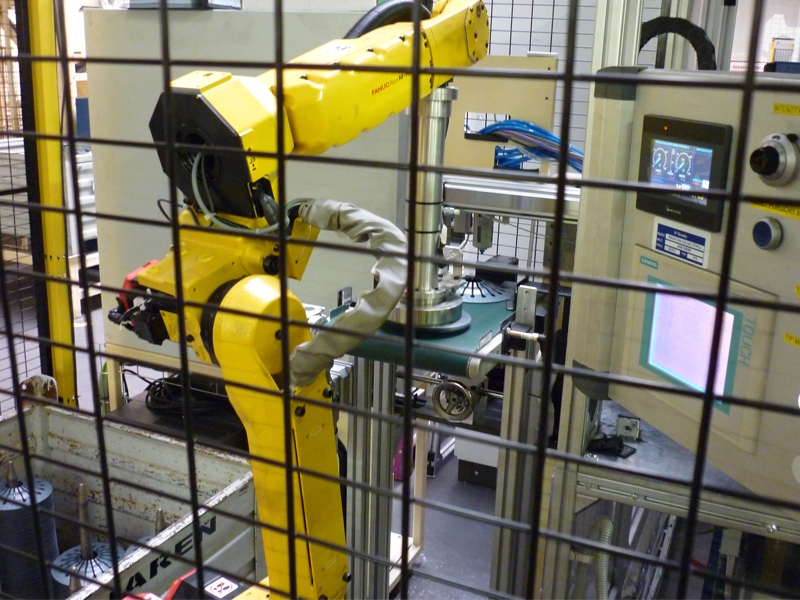

AZS.2 – ROBOTIC WORKSTATION X-RUNNER-YELLOW FOR IMPACT TESTING OF METALS

Description:

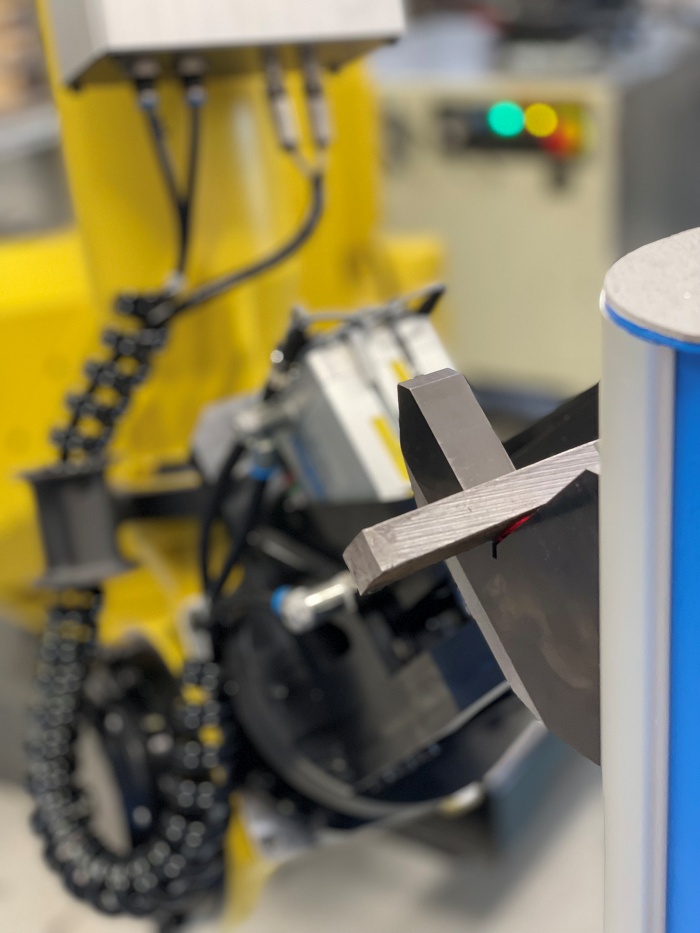

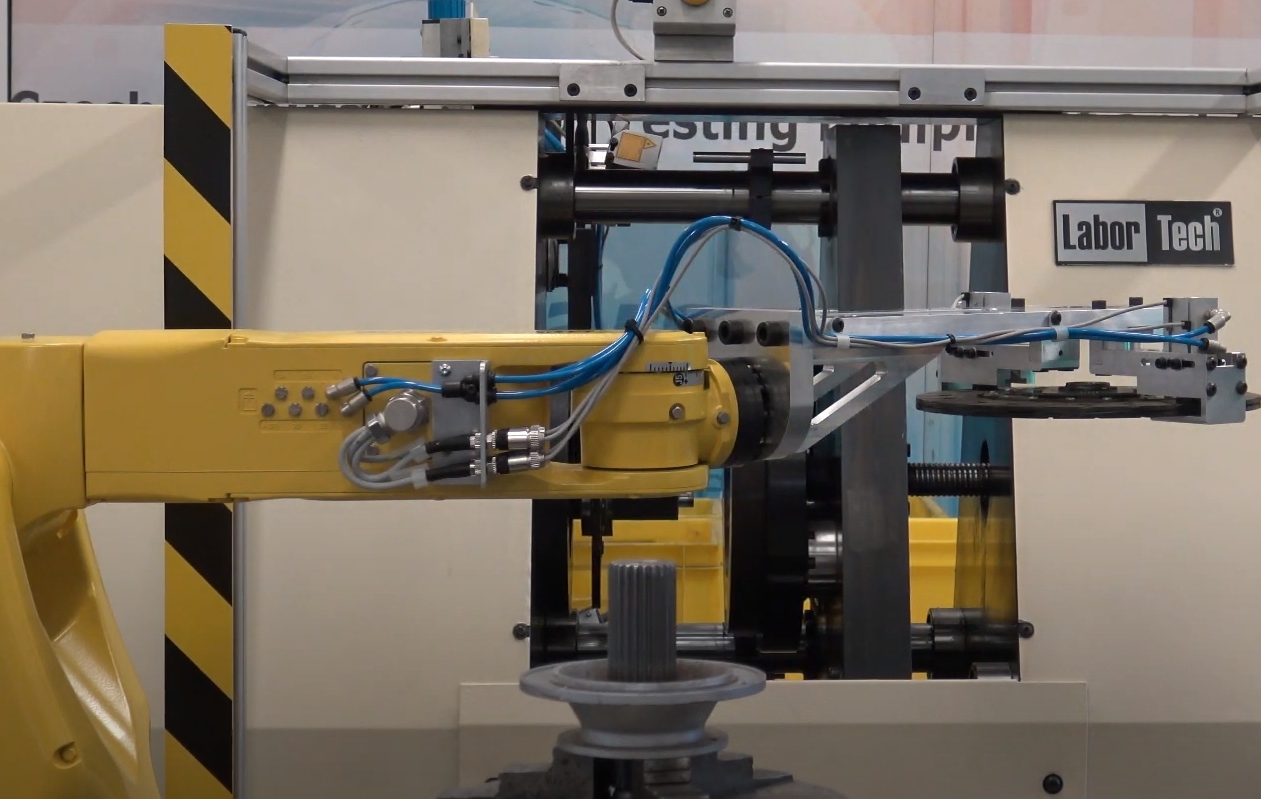

Automated robotic systems X RUNNER-YELLOW designed for precise and fast handling of notched toughness samples in conjunction with impact hammers of the LABORTECH company CHK series. These robotic systems are manufactured in modifications for multiple temperature chambers with the ability to operate two impact hammers at the same time with one robot. Based on customer requirements, we are able to precisely specify the given robotic workplace, make a 3D design and process simulation.

Features:

Modular and economical system for operating one or more machines and temperature chambers

Low operating and maintenance costs including 100% machine utilization (3-shift operation).

Sample loading into the impact hammer within 5 seconds including punching. Max. weight 3 kg.

X RUNNER control system – SIEMENS Simatic S7 1500 – FANUC robot

Application – Standards:

Automated testing of notched specimen in accordance with EN ISO 148-1, EN ISO 148-2, ASTM E23.

Expandable accessories:

Different types of containers depending on the type of samples, sample dimension measuring device with the OPTOLab 55 II system, marking and identification devices, various sample cooling chambers – the LABCool system, special robotic grippers, boxes for collecting punched samples, conveyor systems, extended container systems, etc.

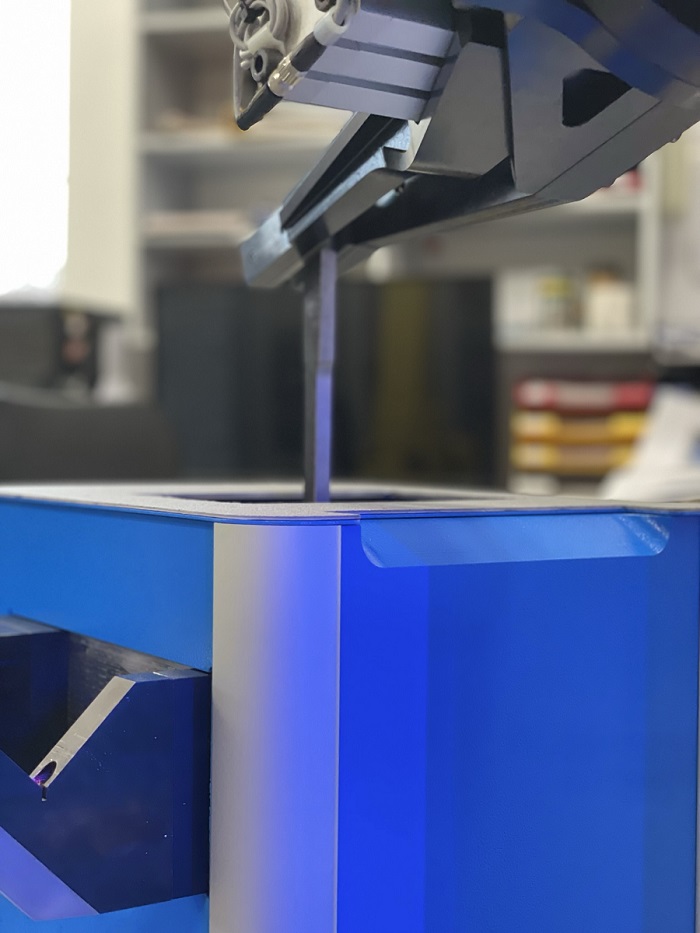

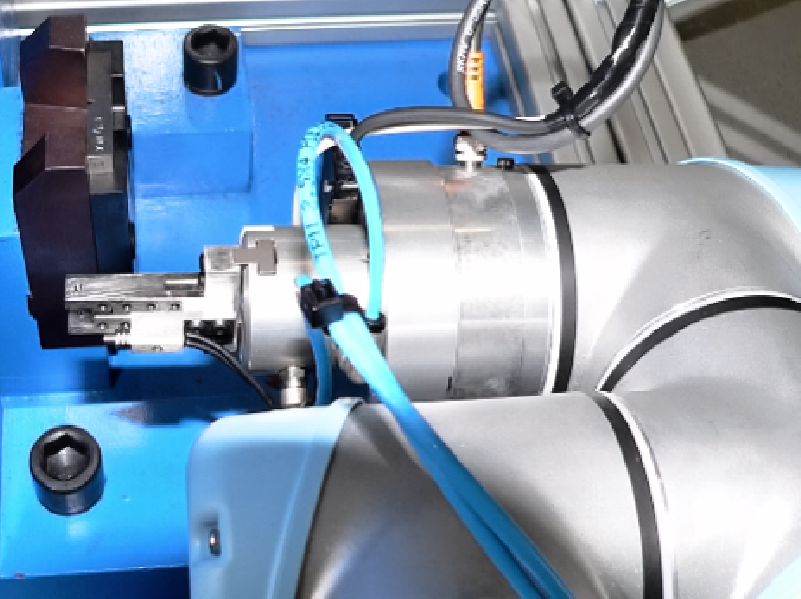

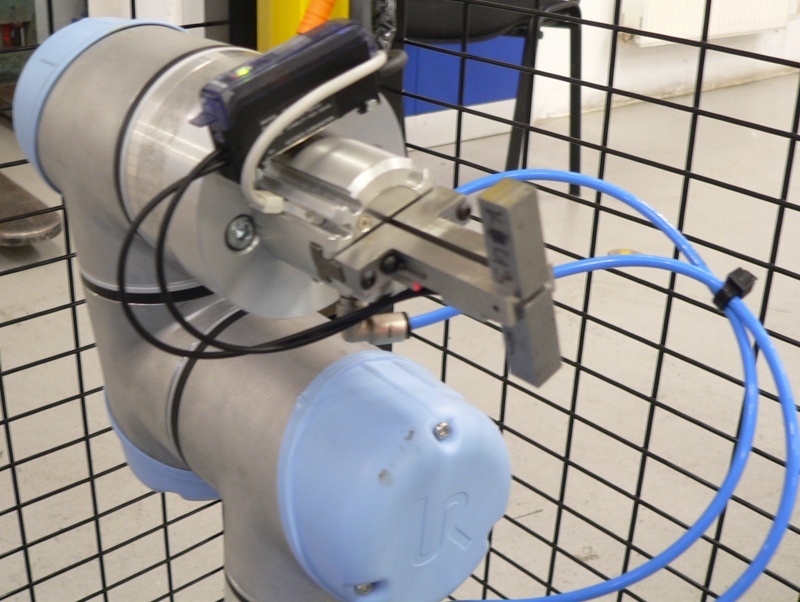

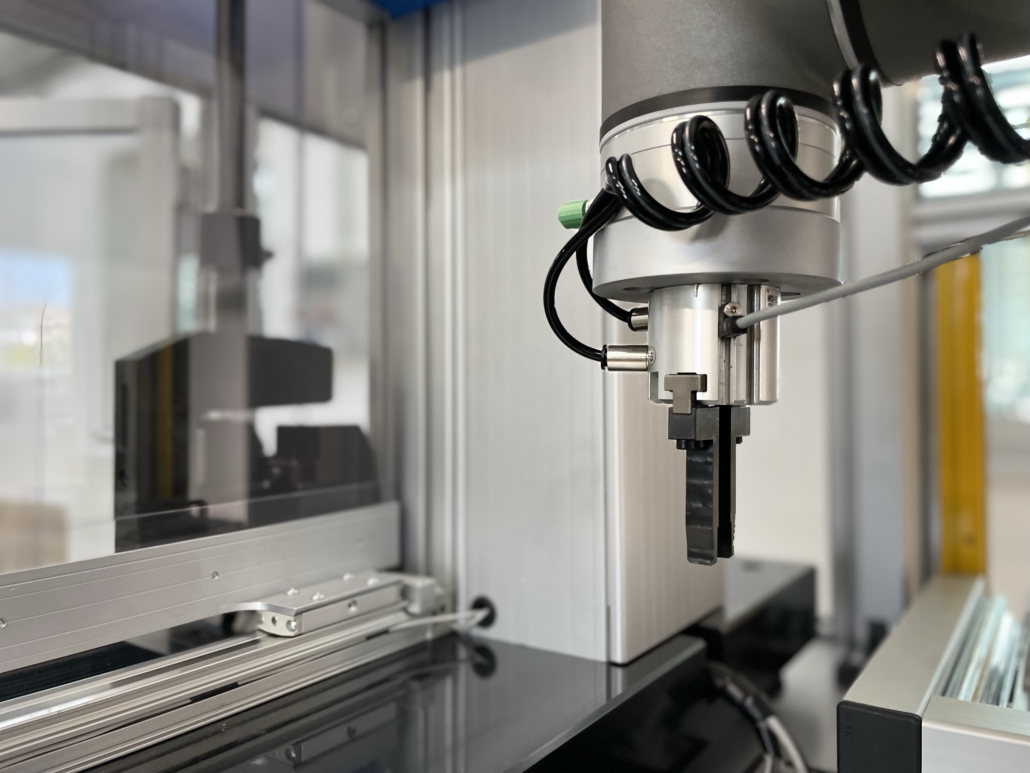

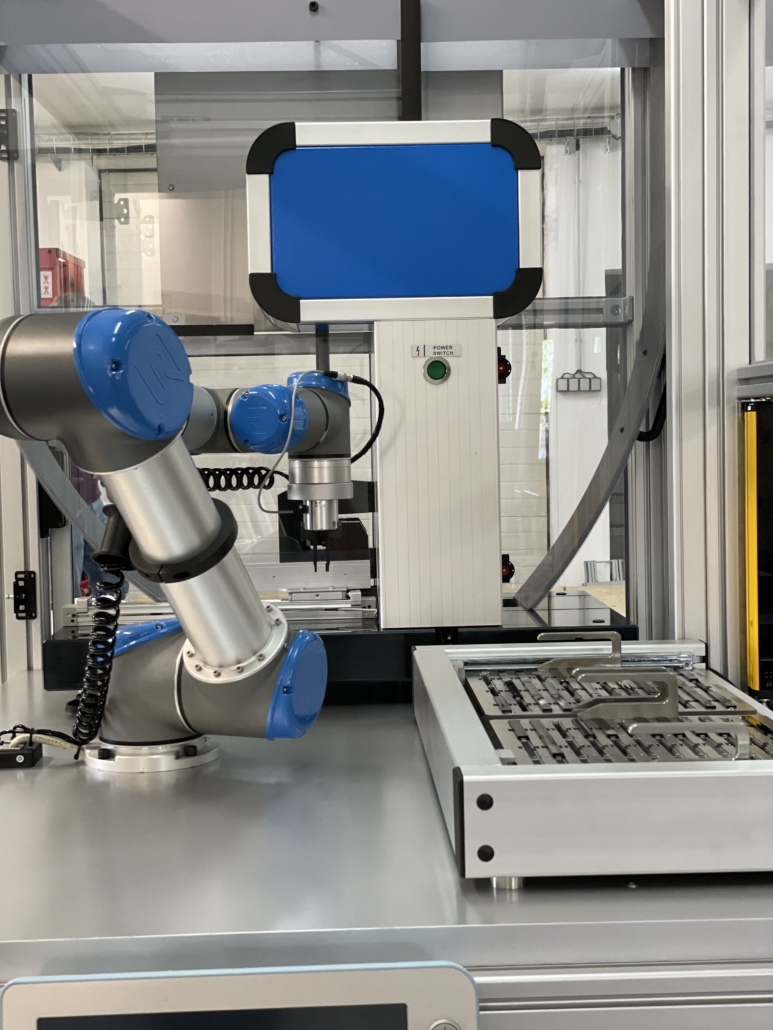

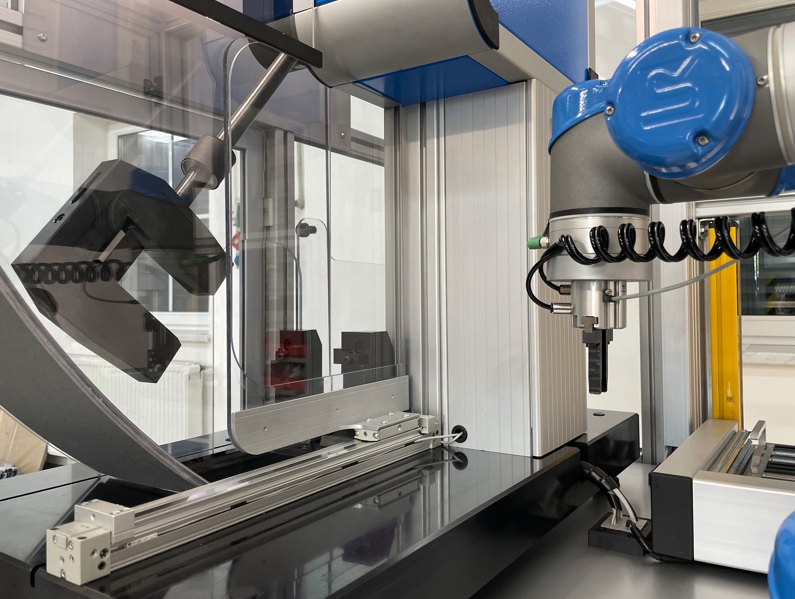

AZS.2 – X-RUNNER-BLUE ROBOTIC WORKSTATION FOR IMPACT TESTING OF METALS

Description:

Automated robotic systems X RUNNER – BLUE designed for precise and fast handling of notched toughness samples in conjunction with LABORTECH impact hammers of the CHK series. These robotic systems are manufactured in several modifications depending on how many samples will be tested within 24 hours, what types of samples and at what temperatures. Based on these requirements, the given robotic workplace is precisely specified. he given robotic workplace is precisely specified.

Automatizované testování zkušebního tělesa s vrubem v souladu s normami

Features:

Modular and economical system for operating one or more machines and temperature chambers

Low operating and maintenance costs including 100% machine utilization (3-shift operation).

Sample loading into the impact hammer within 5 seconds including punching. Max. weight 1 kg.

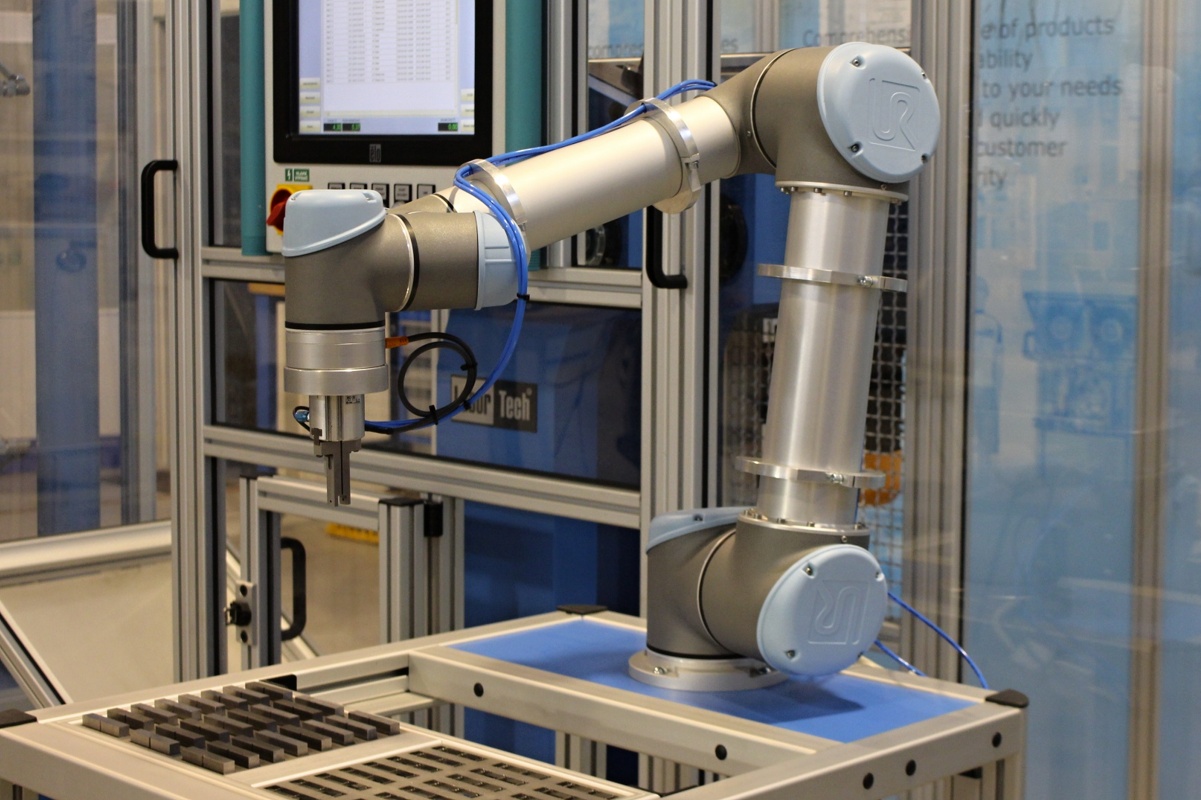

X RUNNER control system – SIEMENS Simatic S7 1500 – UR.

Application – Standards:

Automated testing of notched specimen in accordance with EN ISO 148-1, EN ISO 148-2, ASTM E23.

Expandable accessories:

Different types of containers depending on the type of samples, sample dimension measuring device with the OPTOLab 55 II system, marking and identification devices, various sample cooling chambers – the LABCool system, special robotic grippers, boxes for collecting punched samples, conveyor systems, extended container systems, etc.

MEZERA

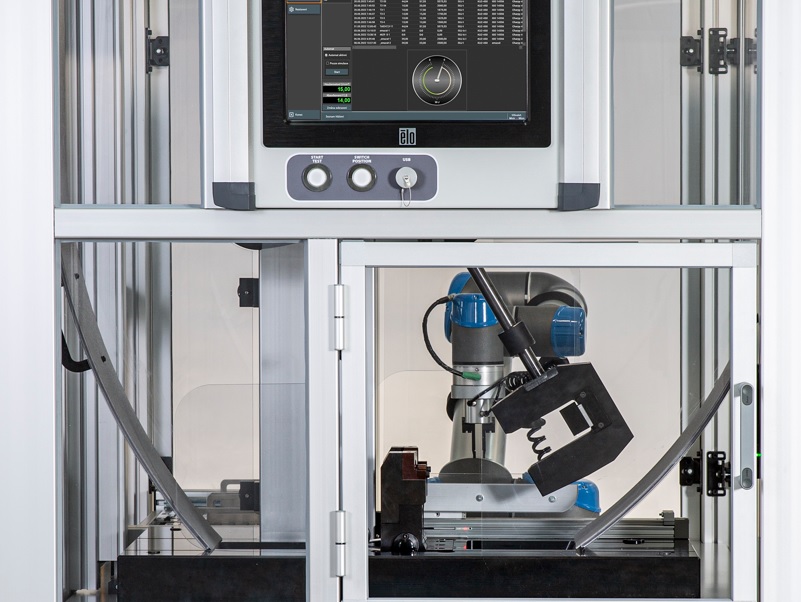

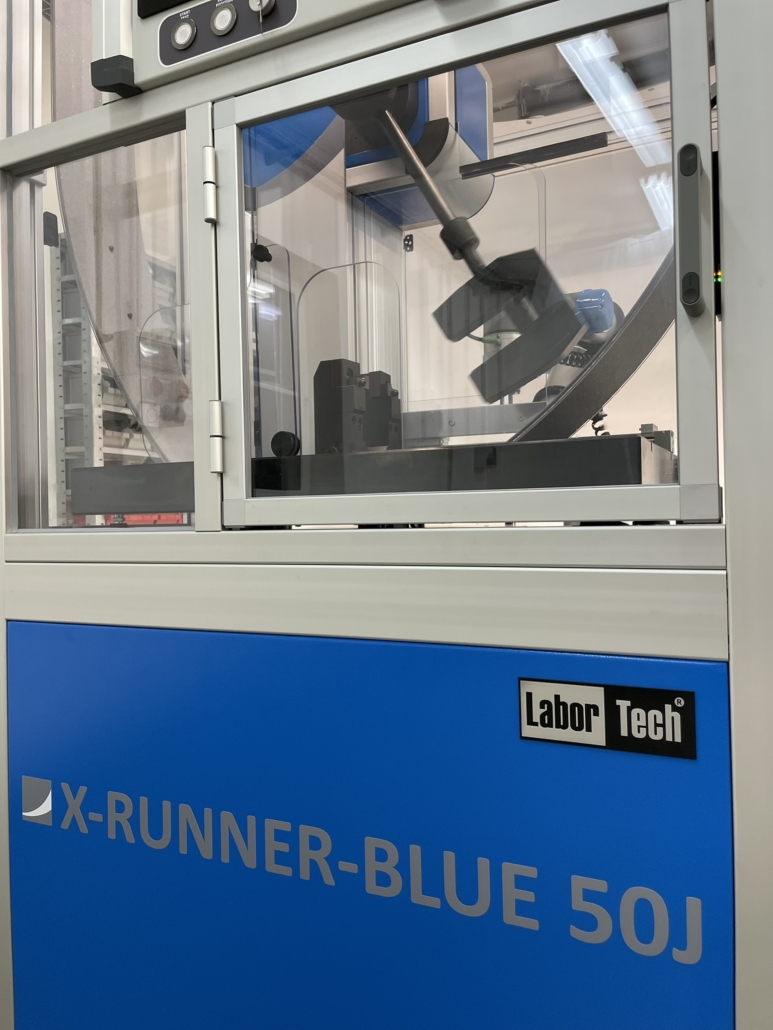

AZS.2 – ROBOTIC WORKSTATION X-RUNNER-BLUE 50J FOR IMPACT TESTING OF PLASTICS

Description:

The automated robotic systems X RUNNER – BLUE 50J are designed for precise and fast handling of plastic samples for notch toughness measurement in conjunction with LABORTECH impact hammers of the CHKTest series. These systems are available in several modifications that adapt to the number of samples tested within 24 hours, the type of samples and the testing conditions, including temperature. Based on these parameters, a specific robotic workplace is precisely specified to meet the customer’s requirements.

Automatizované testování zkušebního tělesa s vrubem v souladu s normami

Characteristic features:

Modular and economical system with the possibility of customization according to customer requirements.

Low operating and maintenance costs including 100% machine utilization (3-shift operation).

Sample loading into the impact hammer within 5 seconds including punching. Max. sample weight 1 kg.

X RUNNER control system – SIEMENS Simatic S7 1500 – Universal Robots.

Application – Standards:

Automated testing of plastic test specimens in accordance with ISO 179-1: Plastics — Determination of Charpy impact properties, ISO 180: Plastics — Determination of Izod impact strength, ASTM D256: Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics, ISO 8256: Plastics — Determination of tensile-impact strength

Expandable accessories:

Different types of containers depending on the type of samples, sample dimension measuring device with the OPTOLab 55 II system, marking and identification devices, various sample cooling chambers – the LABCool system, special robotic grippers, boxes for collecting punched samples, conveyor systems, extended container systems, etc.

AZS.2 – ROBOTIC WORKSTATION X-RUNNER-BLUE 50J FOR IMPACT TESTING OF PLASTICS

Description:

The automated robotic systems X RUNNER – BLUE 50J are designed for precise and fast handling of plastic samples for notch toughness measurement in conjunction with LABORTECH impact hammers of the CHKTest series. These systems are available in several modifications that adapt to the number of samples tested within 24 hours, the type of samples and the testing conditions, including temperature. Based on these parameters, a specific robotic workplace is precisely specified to meet the customer’s requirements.

Automatizované testování zkušebního tělesa s vrubem v souladu s normami

Characteristic features:

Modular and economical system with the possibility of customization according to customer requirements.

Low operating and maintenance costs including 100% machine utilization (3-shift operation).

Sample loading into the impact hammer within 5 seconds including punching. Max. sample weight 1 kg.

X RUNNER control system – SIEMENS Simatic S7 1500 – Universal Robots.

Application – Standards:

Automated testing of plastic test specimens in accordance with ISO 179-1: Plastics — Determination of Charpy impact properties, ISO 180: Plastics — Determination of Izod impact strength, ASTM D256: Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics, ISO 8256: Plastics — Determination of tensile-impact strength

Expandable accessories:

Different types of containers depending on the type of samples, sample dimension measuring device with the OPTOLab 55 II system, marking and identification devices, various sample cooling chambers – the LABCool system, special robotic grippers, boxes for collecting punched samples, conveyor systems, extended container systems, etc.

MEZERA

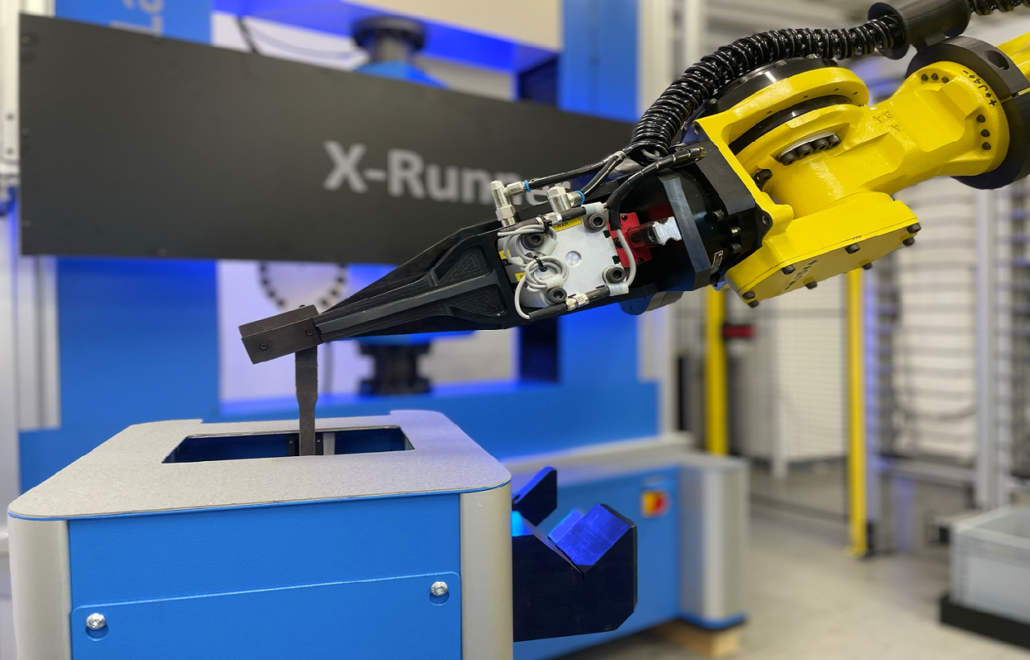

X-RUNNER-TANDI – COMBINED SYSTEMS FOR TENSILE AND IMPACT TESTS

Automated testing of metal in tension according to EN ISO 6892-1 and in impact according to EN ISO 148-1

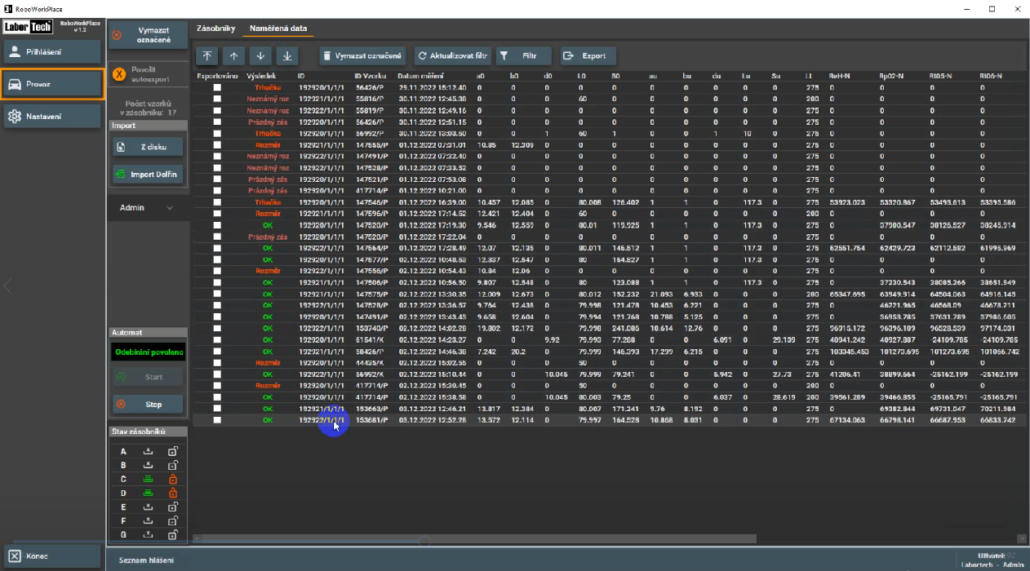

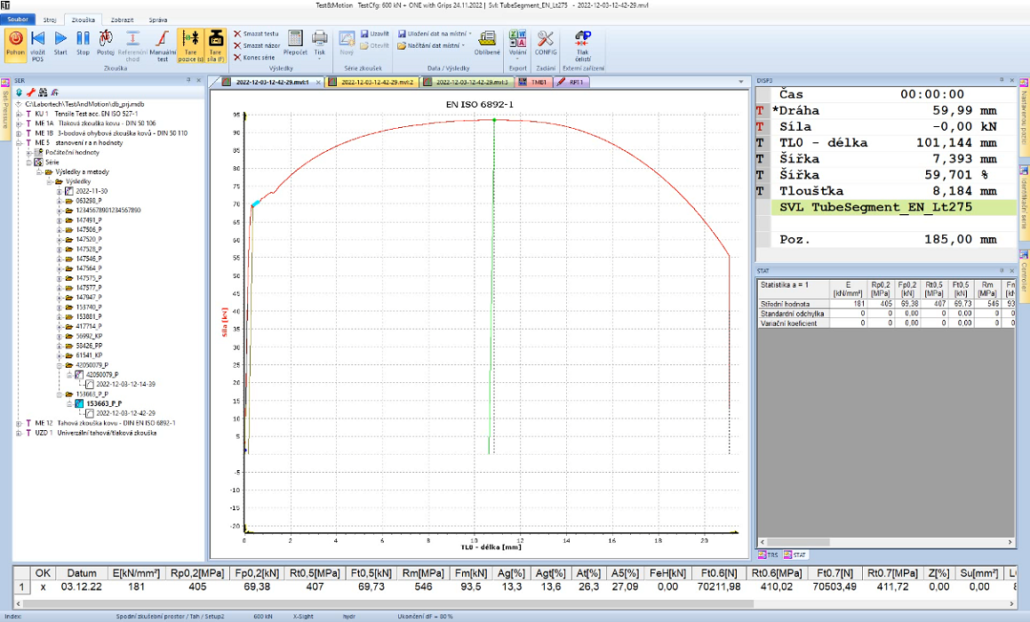

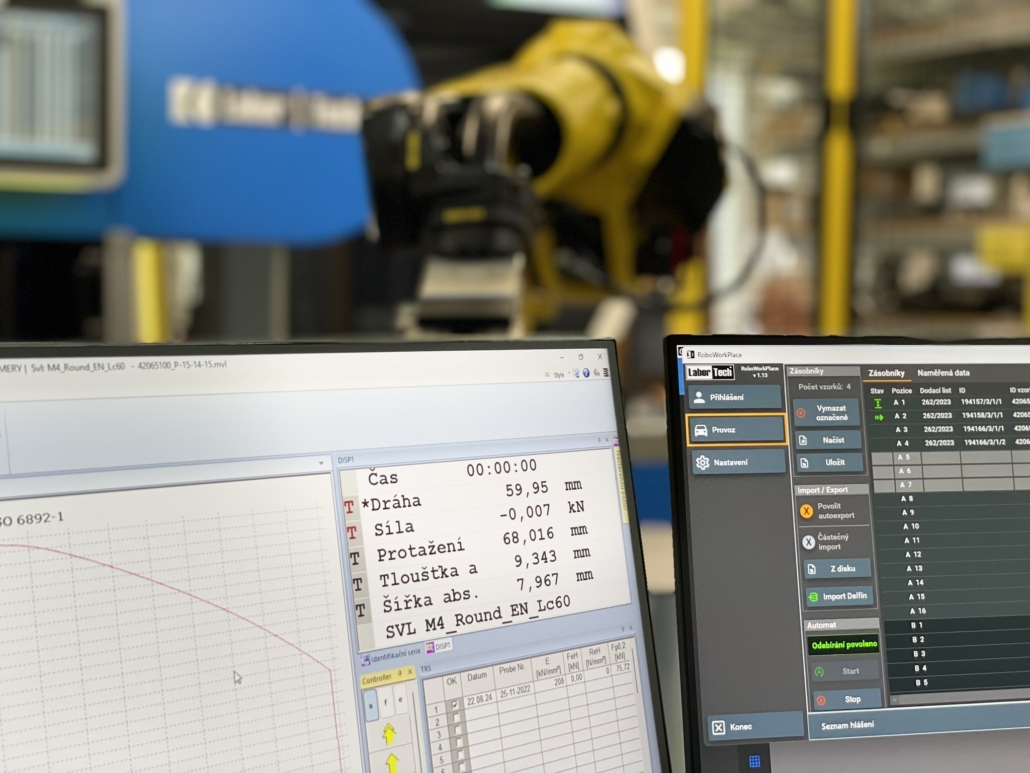

The combined robotic workstation X-RUNNER TANDI from LABORTECH represents a cutting-edge solution for automation of testing processes, integrating advanced technologies and state-of-the-art equipment for maximum efficiency and measurement accuracy. The entire X-RUNNER TANDI system is controlled by RoboWorkPlace software and local IMPACTTest and T and M software. This comprehensive system enables fully automated operation with minimal human intervention, which increases productivity and eliminates the risk of human error. The combined robotic workstation X-RUNNER TANDI thus represents an ideal solution for modern testing laboratories that require the highest standards of accuracy, reliability and efficiency.

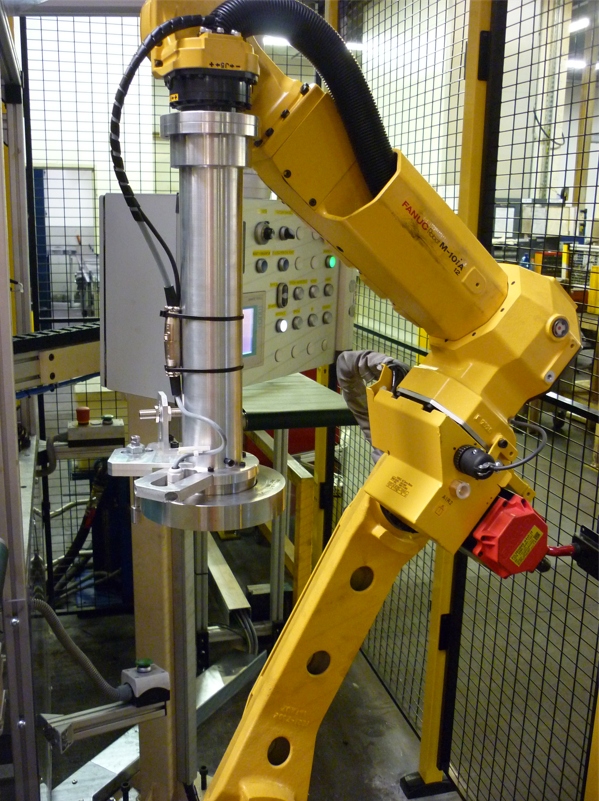

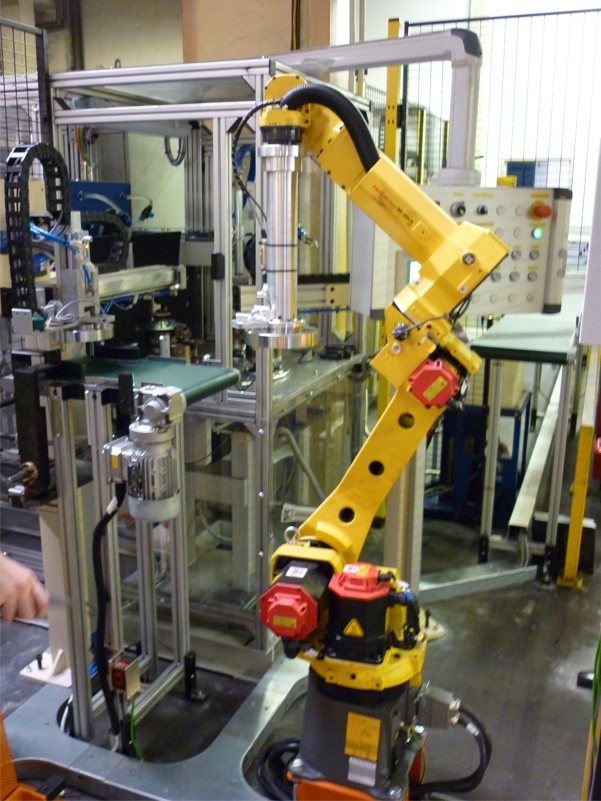

AZS.3 – COMBINED ROBOTIC WORKSTATION X-RUNNER TANDI FOR TENSILE AND IMPACT TESTING OF METALS

Description:

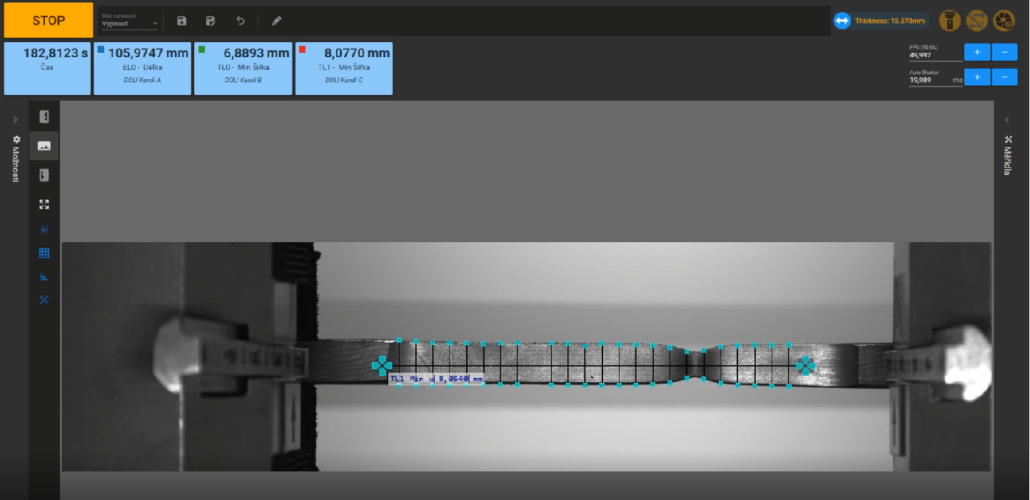

The combined automated robotic testing system X-RUNNER TANDI is designed for precise and fast handling of samples for tensile and impact testing in one system. In conjunction with the electromechanical or hydraulic testing machines LabTest E and H series and the impact hammer of the CHKTest series, it forms a comprehensive solution for automated testing. This robotic system is produced in several modifications, which are mainly customized according to specific needs.

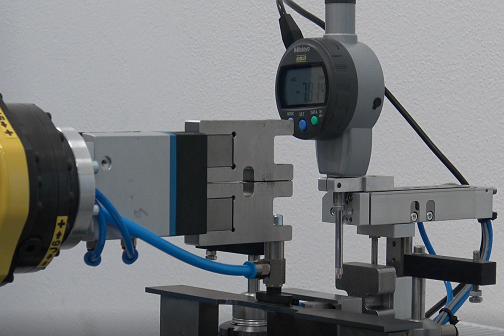

Characteristics:

Automatically distinguishes different types of samples

Non-contact system for measuring sample dimensions – LME 50 – flat, segmented and round up to 20kg

DOUBLE ONE 1 camera systems for measuring relative elongation and contraction.

Container system designed for 112 samples without any difference in shape and size up to 50 mm thick

Container system for impact strength samples

LABCool sample cooling chamber – AUTOMATIC for temperatures up to -80°C

X RUNNER control system – SIEMENS Simatic S7 1500 incl. LCD.

Application – Standards:

Automated testing of standardized samples in accordance with EN ISO 6892-1

Automated testing of notch toughness samples in accordance with EN ISO 148-1

Expandable accessories:

Different types of containers depending on the type of samples, marking and identification devices, data reading from external databases e.g. DELFIN, VIDEO Extensometers, various types of clamping jaws and fixtures, special robotic grippers, hybrid hydraulic units, QR code readers..

MEZERA

X-RUNNER-P FOR TESTING WHOLE PRODUCTS AND PARTS

Automatic robotic testing of entire products and parts according to internal customer standards and regulations

Robotized workplaces for testing parts and components allow you to reduce production costs, increase productivity and perform 100% control of the mechanical properties of the part. System integration of robots improves production processes, brings a high level of repeatability and provides a return on investment usually within 3 years. Robotization of production with the X-RUNNER system is a way to increase the accuracy, stability and efficiency of processes.

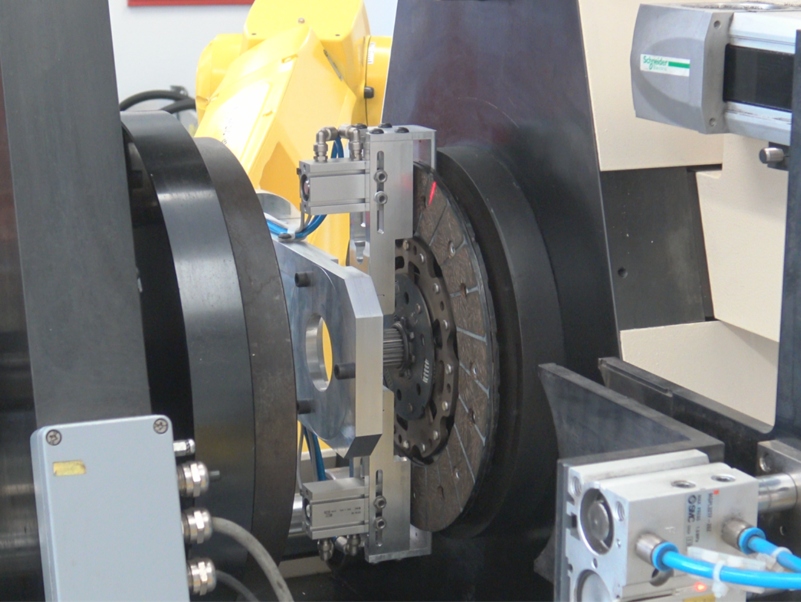

AZS.4 – ROBOTIC WORKSTATION X-RUNNER-P FOR TESTING PKW CLUTCHES

Description:

Complete automated line designed for production and 100% mechanical inspection and adjustment of PKW clutches including balancing according to a special dynamic adjustment algorithm and special camera inspection with the possibility of dividing into IO and NIO+ and NIO- pieces. The line consists of several separate parts. The company LABORTECH ensures the functionality of the entire line.

Characteristic features:

Complete line with the following parts: assembly part of the line (assembly of the clutch, pressure plate and spring) test part (mechanical inspection including adjustment, clutch balancing, XTD fixation, preservation), division system into IO, NIO+ and NIO- parts.

Handling of clutches ensured by KUKA robot and continuous manipulators including conveyor belts.

Identification and history of parts via MARKRATOR

SIEMENS Simatic S7 1500 control system incl. LCD, Integrated PC incl. BALANCERTest, EDHTest software etc.

Total cycle time of the line at the input – 21sec

Application – Standards:

AUTOMOTIVE – assembly and testing of automotive PKW clutches – measurement of mechanical properties of the clutch, dynamic automatic balancing, marking and identification equipment…

Expandable accessories:

Different types of containers depending on the type of samples, optical inspection device for correct riveting, MARKRATOR marking and identification device, special robotic grippers, boxes for identification of IO and NIO parts, conveyor systems, extended container systems, etc.

AZS.8 – X-RUNNER-P ROBOTIC WORKSTATION FOR SLAT TESTING

Description:

Combined robotic line – ROBOT-MANIPULATOR designed for 100% mechanical inspection of slats using the ABCD system (compression, extension, rotation and monitoring of the slat loading process) with automatic unloading and selection of defective parts according to the given error. The line consists of several separate parts. The LABORTECH company ensures the functionality of the entire line.

Characteristic features::

Complete line with the following parts: assembly part of the line (assembly of the cover, pressure plate and spring) test part (mechanical inspection including adjustment, balancing of clutch, fixation of XTD, preservation), division system into IO, NIO+ and NIO- parts.

Handling of clutches is ensured by a KUKA robot and continuous manipulators including conveyor belts.

Identification and history of parts via MARKRATOR

SIEMENS Simatic S7 1500 control system incl. LCD, Integrated PC incl. BALANCERTest, EDHTest software etc.

Total cycle time of the line at the input – 18sec

Application – Standards:

AUTOMOTIVE – assembly and testing of automotive PKW lamellas – measurement of mechanical properties of the lamella including automatic division into IO and NIO, etc.

Expandable accessories:

Different types of containers depending on the type of samples, optical inspection device for correct riveting, MARKRATOR marking and identification device, special robotic grippers, boxes for identification of IO and NIO parts, conveyor systems, extended container systems, etc.

MEZERA

AZS.10 – X-RUNNER-P ROBOTIC WORKSTATION FOR SPRING TESTING

Description:

Input handling and loading robotic system designed for precise and fast handling of PKW springs of all kinds. The entire system continues with another line of thermal and mechanical processing also supplied by LABORTECH.

Characteristic features:

Input handling line for automated removal of PKW springs from standardized pallets.

Blade placement on a centering conveyor on the induction hardening unit or directly in the process of further evaluation.

Testing of the complete range of PKW springs with compatible exchangeable magnets

Total cycle time at input – 9 seconds

X Runner controller in conjunction with Yellow Runner Series BR – SIEMENS Simatic S7 1500 incl. LCD – RUNNERTTest v. 2

Application – Standards:

AUTOMOTIVE – assembly and testing of springs – measurement of mechanical properties of springs, selection for IO and NIO etc.

Expandable accessories:

Different types of containers depending on the type of samples, optical inspection device for correct riveting, MARKRATOR marking and identification device, special robotic grippers, boxes for identification of IO and NIO parts, conveyor systems, extended container systems, etc.

Contact

LABORTECH s.r.o. , Rolnická 1534/130a, 747 05 Opava, Czech Republic

Research & Development

Reducing energy intensity We increase your productivity Development and implementation

News & Events