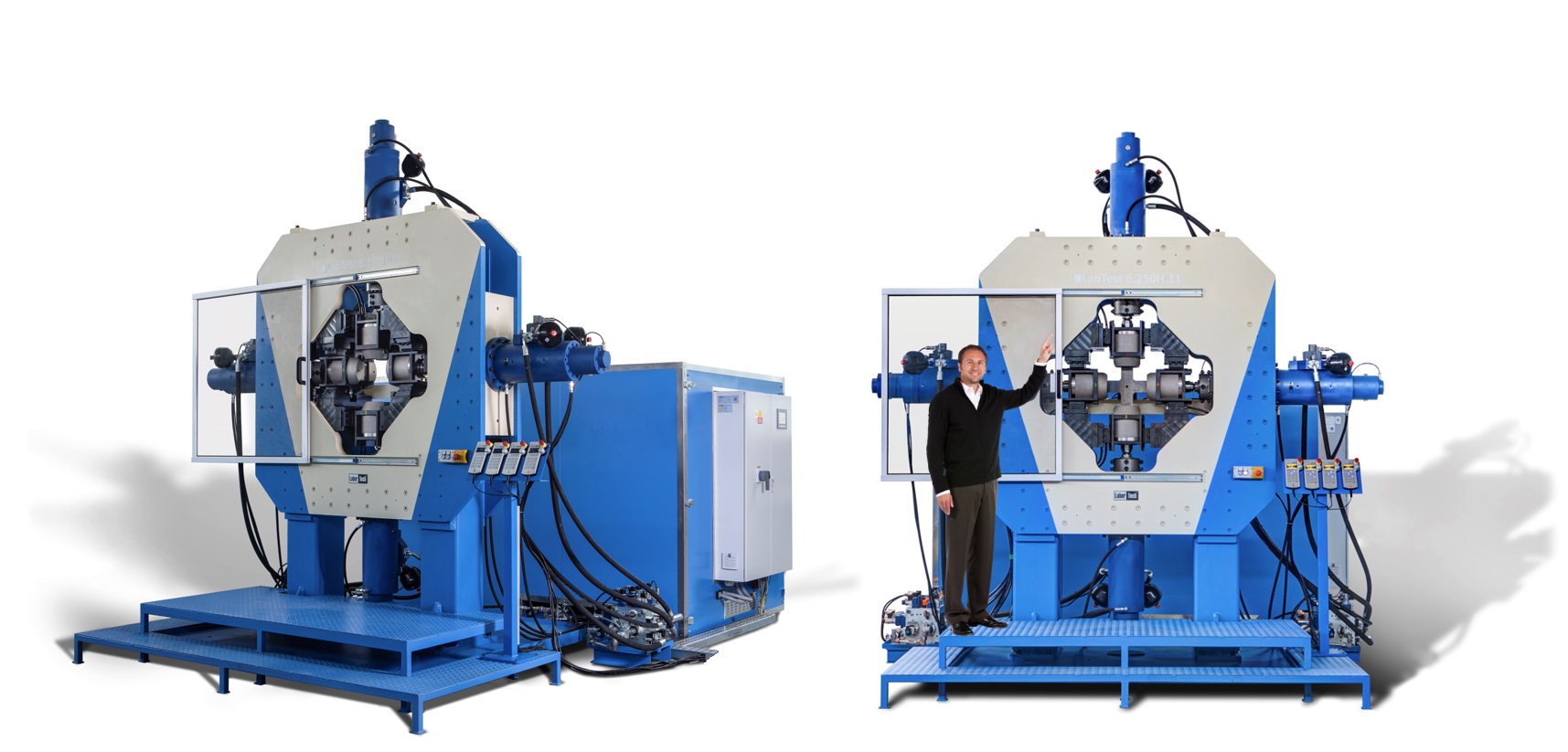

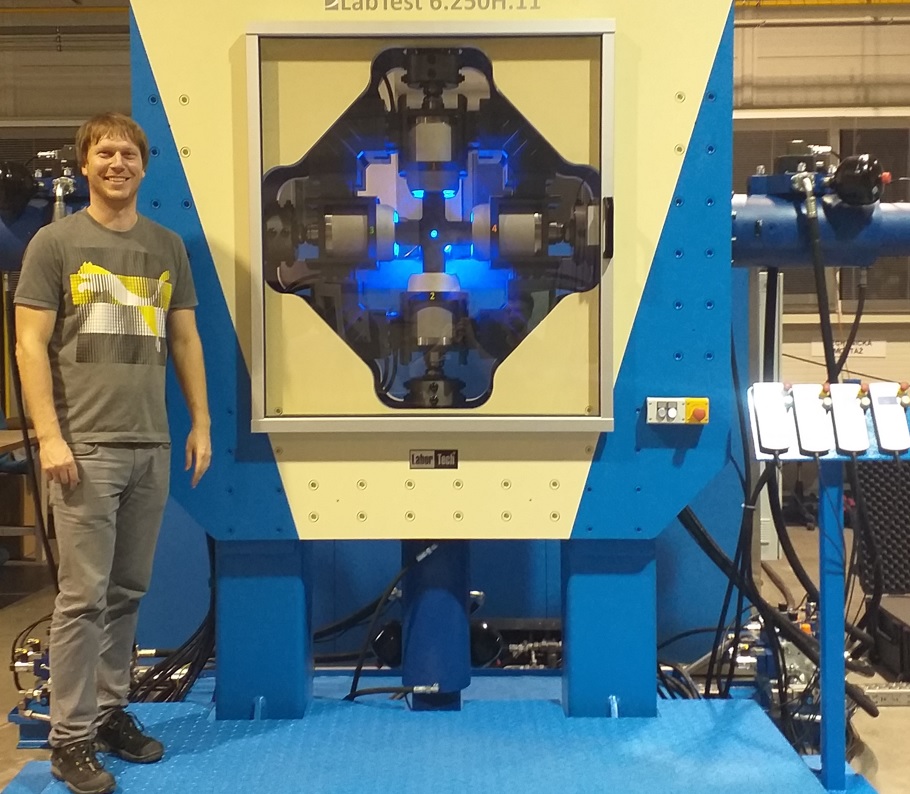

H.11 – BIAXIAL SERVO HYDRAULIC DYNAMIC TESTING MACHINES UP TO 250 kN

Servohydraulic dynamic biaxial testing machines of the H.11 series are designed to perform low and high cycle fatigue tests of fracture toughness, crack propagation, etc. This series of machines is characterized by high rigidity of the frame with long life, mechanical resistance and self-absorption of resonances. The wide range of Hydraulic units allows you to dynamically load samples up to Fmax. 250kN and frequency up to 50 Hz.

Download:

MEZERA

Key features of H.11 series

MEZERA

Mezera

- Robust vertical stand design with extremely high lateral rigidity, resonant and mechanical resistance in dynamic mode for each test axis of the machine.

- Powerful compact hydraulic units of the HAD series with low noise level designed for fatigue tests with water cooling

- Diagnostics of the hydraulic unit HALT 18 controlled by TOUCH LCD SIEMENS at standard.

- Control of individual axes by proportional or servo valve in power and position loop.

- Complete test evaluation and control is provided by Test & Motion material testing software – DYNPACK.

- The H.11 series machines comply with all the above-mentioned EC directives on machinery and equipment and work in accordance with the new safety functions according to EN ISO 13850-SIL 1/PL.

- Combined torsion load cells located on the piston rod operating in the accuracy class according to EN ISO 7500-1, ASTM E4 with the possibility of linearization.

- The compact measuring and control electronics of the EDCi Control – BIAXIAL series are preferably designed to handle this top application. Synchronization of all measuring and control channels with sampling frequency 10kHz in real time…. Analog signal resolution level ± 250,000 divisions (20 ms).

- Integrated BENTROD measuring and setting unit for each axis designed for evaluation and optimization of concentric and edge alignment correction according to ASTM E1012

- Dynamic hydraulic grips with wedge pressure designed for clamping cross flat specimens with centering.

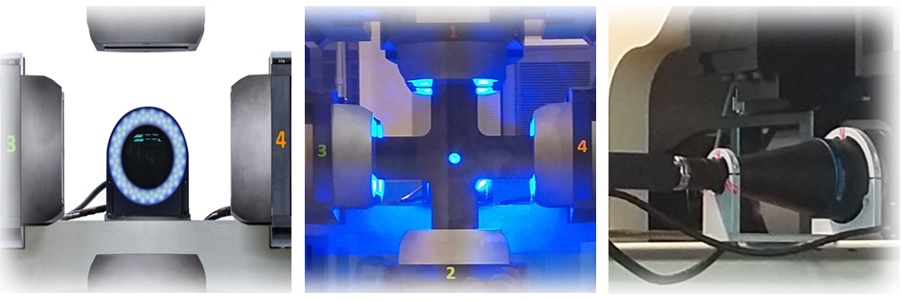

- Unique advanced axial, transverse and biaxial video extensometer EOX using the latest digital image correlation technology thanks to the telecentric lens

- High-precision tests with temperature chamber or high-temperature furnace.

MEZERA

Compact and reliable test systems for development

Biaxial machines – the H.11 series system from the LABORTECH company enable test technicians to simulate real real and demanding conditions on samples. This device can stress the sample in several directions at once with any coefficient of load asymmetry and at the same time guarantees test technicians to have 100% control over this process.

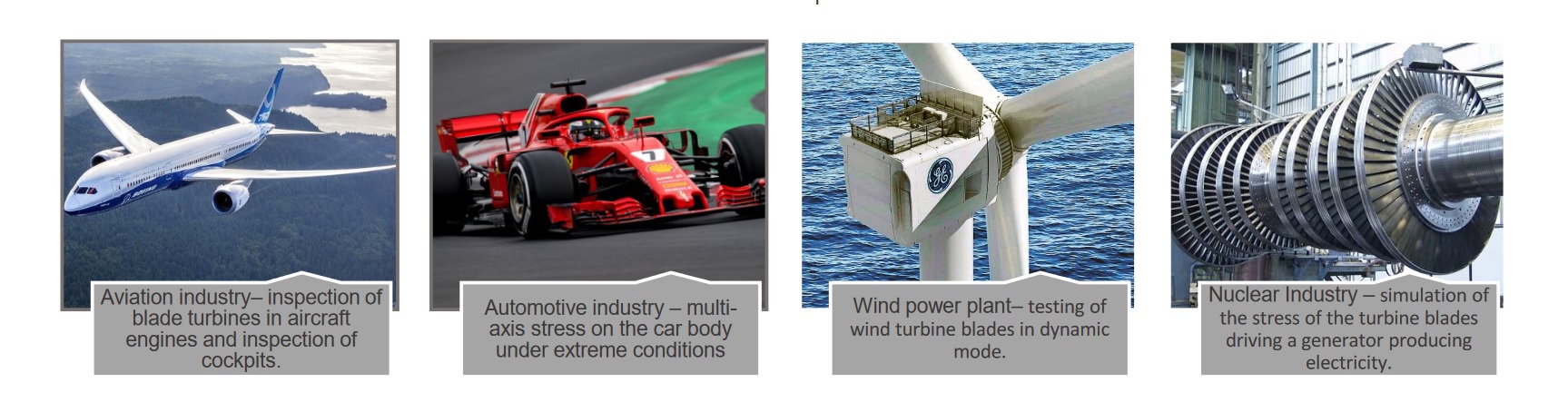

The LabTest H.11 Series Servohydraulic Testing System provides a complete spectrum of static and dynamic planar biaxial material stress testing, high cycle fatigue, material crack growth, and environmental simulation on a variety of materials. These are mainly the aerospace, automotive and nuclear industries and the development of wind turbine blades.

For all modifications of the LABORTECH H.11 biaxial test systems produced by us, the mechanical and hydraulic parts can be combined modularly using any additional accessories. Many optional functions allow you to perform both static and dynamic tests in one or more X and Y axes, both positional and force loops, and to meaningfully and efficiently simulate and test special materials and components in various modes.

Intuitive and trouble-free use of testing software designed for biaxial tests DYNPACK and BENTROD produced by LABORTECH guarantees you a reliable declaration of results and, above all, continuous data collection from all X and Y during continuous testing.

MEZERA

VIDEOS of the LabTest H.11 biaxial testing machine

Functional Practical test of H.11 with video extensometer EOX

High temperature tensile tests controlled by tension according to ISO 6892-2 Method A1 with contact extensometer.

Axial adjustment of the machine according to standard E 1012

Tensile test with video extensometer ONE according to standard EN ISO 6892-1.

MEZERA

Do you have questions about our products?

Feel free to contact our product experts.

We look forward to your interest.

–

MEZERA

Test frame of the machine, including special accessories

You will not find a machine with higher rigidity in our portfolio…

Vertical stand frame design with the highest rigidity

Vertical stand frame design characterized by extremely high lateral rigidity, resonant and mechanical resistance in dynamic mode for each test axis of the machine. Mechanical and hydraulic protection of the actuators against impact in all axes. The system is designed with an adjustable CEDEROD leveling device in the load path, including a force sensor for each axis. Special pneumatic damping assembly enabling the elimination of vibrations with an efficiency higher than 95%.

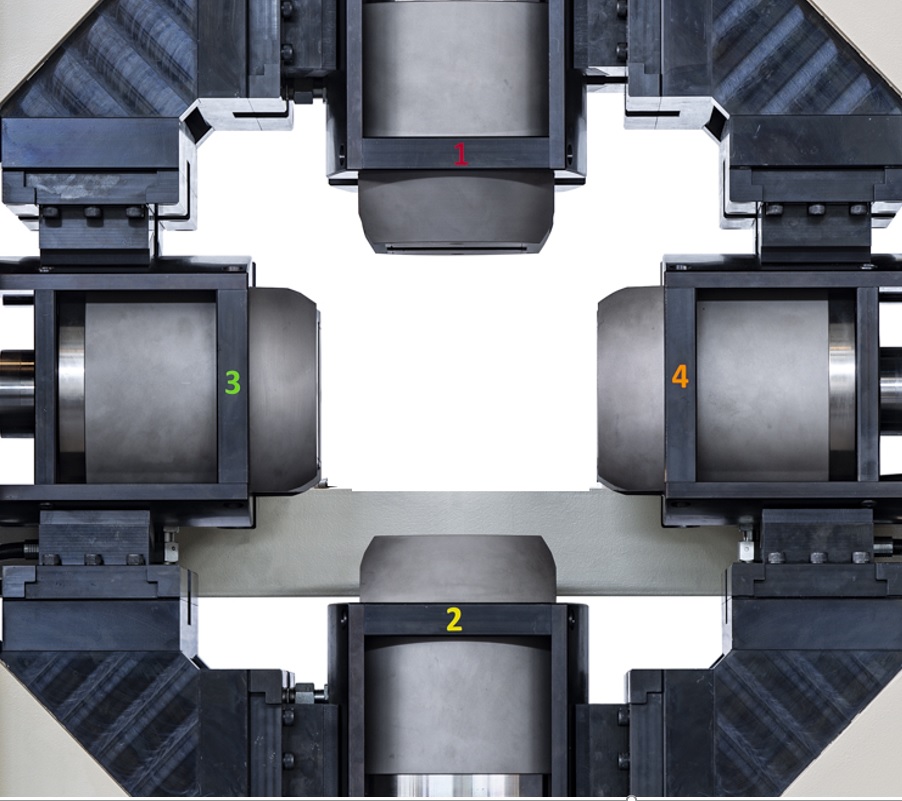

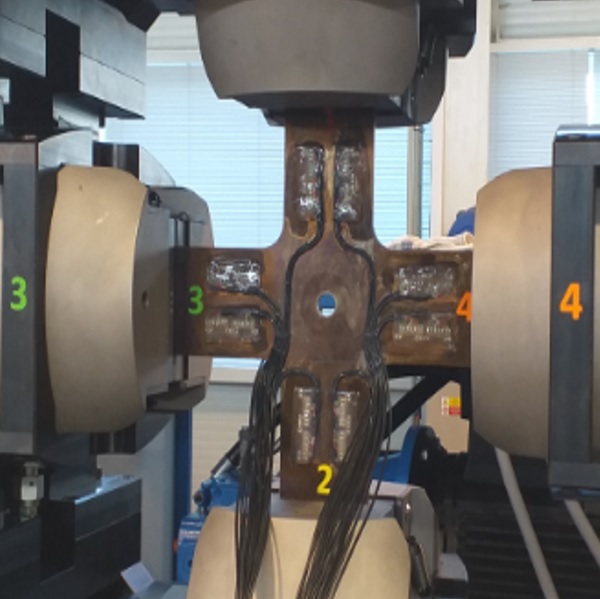

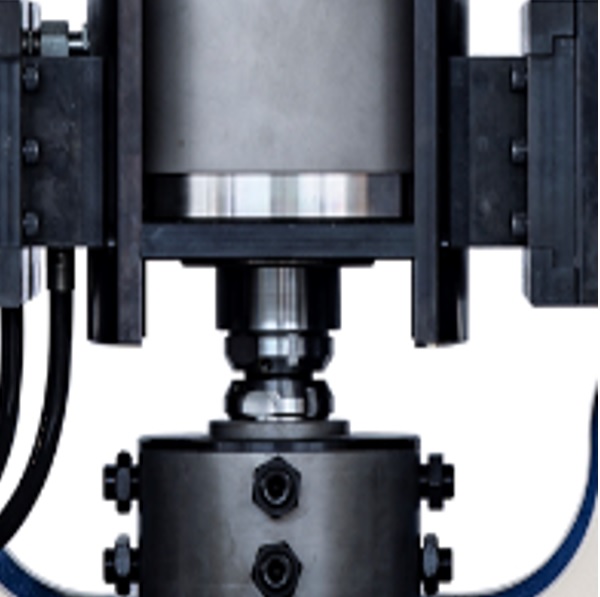

Actuators-drives – hydraulic servo cylinders

The actuators – drives – hydraulic servo cylinders X and Y are arranged at right angles in one plane from the front view. The actuators with a stroke of +/- 50 mm (total stroke 120 mm) used in the frame are specially designed for surface biaxial testing with a small internal oil volume to increase the rigidity of the system. The hydrostatic bearings of each drive with minimal friction allow to guarantee the testing the appropriate rigidity and coaxiality. Integrated acceleration compensation and moment of inertia elimination for high-frequency testing for each axis separately.

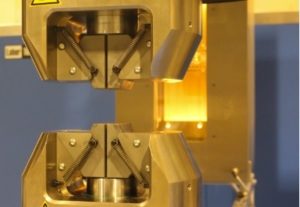

Special wedge dynamic grips with hydraulic pressure

In the load axis, there are special wedge dynamic jaws with hydraulic pressure and an integrated adjustable cage that eliminates rotation, deflection of the entire axis with the possibility of precise setting of the required tolerance and mechanical stop. The hydraulic grips include 4 pairs of flat inserts with a pyramid surface, special centering on a pin, clamping surface 110 x 110 mm, dimensioned for a maximum load of 1300 N / mm2. System for central control of hydraulic grips on individual axes with monitoring of force increase during sample clamping and monitoring of clamping center.

MEZERA

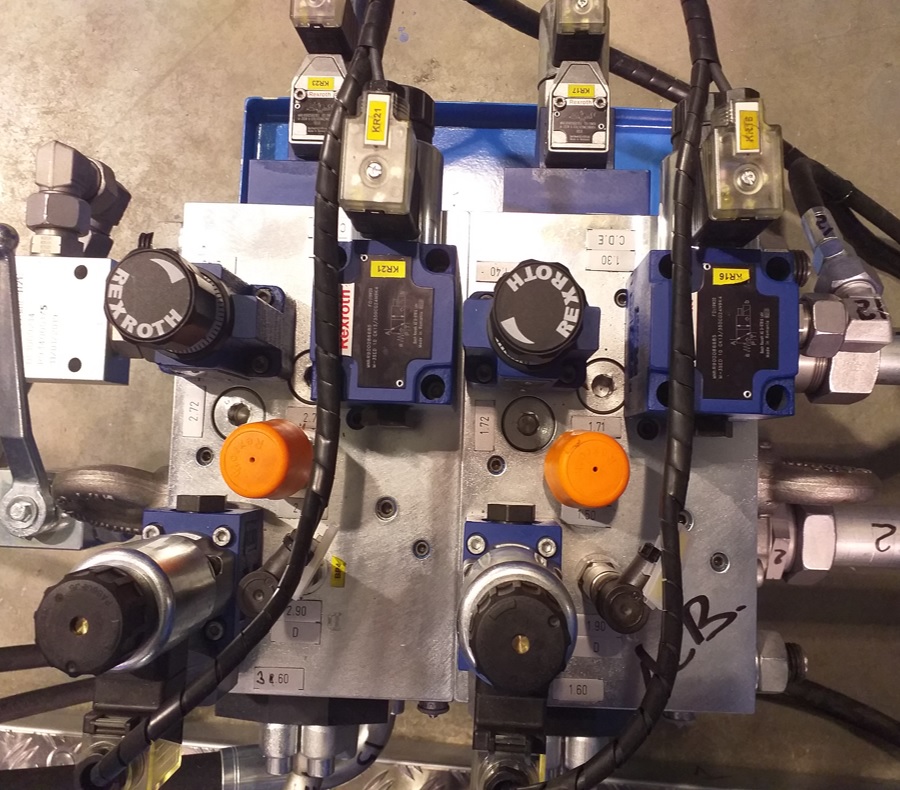

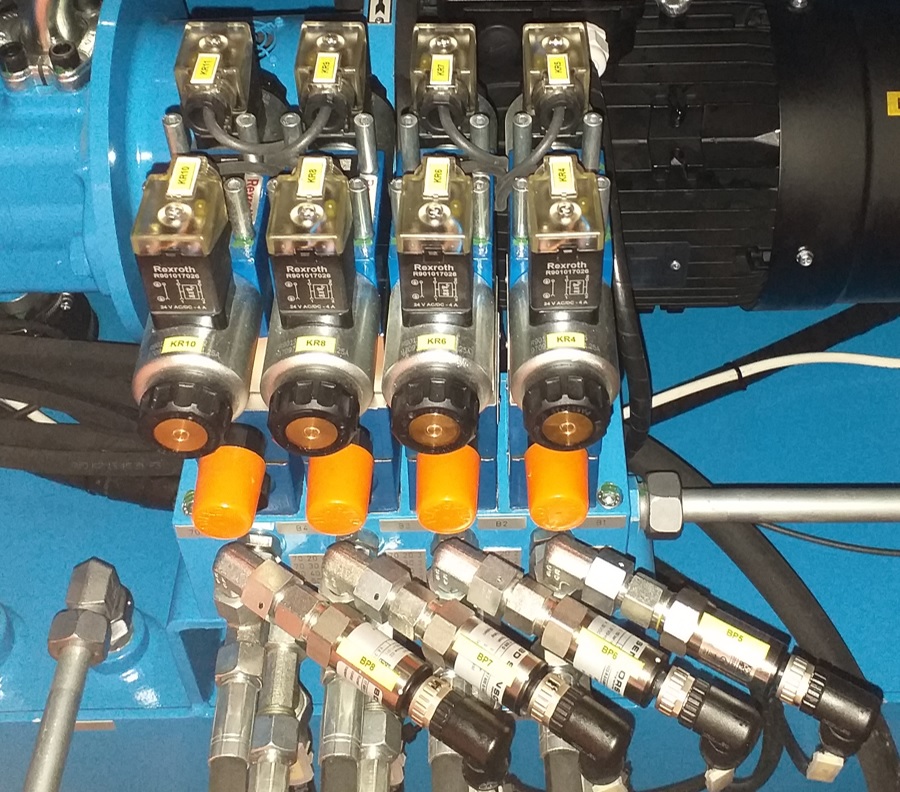

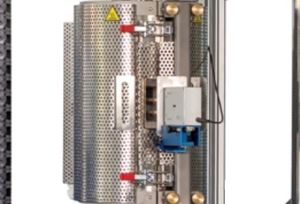

Rexroth Hydraulic compact unit

The harmony of pressures and flows defines the accuracy and reliability of the system.

Efficiency comes first

The hydraulic unit is designed as a compact hydraulic unit designed for fatigue tests with water cooling. All these parts are located on a steel welded tank with a sump. The energy-saving variable displacement axial pump ensures maximum efficiency of the hydraulic system and regulates the flow of the supplied medium as required.

HAD has a G500Q4 system for controlling hydraulic jaws. Pressure circuit 450 bar with pressure transducer, for 4 jaws, throttle valves, manual pressure valves, etc.

System diagnostics and control

The Rittal central control panel is equipped with the HALT 18 – Diagnostic control system with HA system status, pressure and service interval monitoring system consisting of SIEMENS SIMATIC electronics. The message is displayed on the SIEMENS LCD touch screen. This system allows you to perform remote diagnostics from the control room, office or even a mobile phone.

Automatic interlocks protect against unintentional damage due to high temperature or high / low fluid level or oil leakage from the system. For greater protection, adjustable user limits for monitoring various HU parameters are available.

Quiet, clean and compact design

Covering is done with a special anti-noise cover PAC 250 consisting of polyurethane panels with a guaranteed total noise HU – <72 dB. Easy access from all sides using quick couplings allows easy handling around the HU (filter change, oil change, etc.). Thanks to the force-block suspension, the HU can be placed directly on the floor of the test room.

The connection between the HAD hydraulic unit and the machine frame is made using the VOSSFORM system, including a pressure test by Rexroht. Oil stains and gutters have no chance.

MEZERA

Measuring and control electronics

Perfect machine control, stability of measured data and safety are our priorities…

Synchronization of all axes is the basis of testing on a biaxial machine.

The compact electronics of the EDCi Control – BIAXIAL series are preferably designed to handle this top application. Synchronization of all measuring and control channels with a sampling frequency of 10 kHz in real time allows you to control all four axes of the biaxial machine LabTest 6.250 H.11. Configuration and parameterization using the installation center computer software.

RMCi7 series remote control set with OLED display integrated CENTRAL STOP, control of individual jaws on parameters for each axis separately, etc. Resolution level of analog signals ± 250,000 divisions (20 ms). Internal frequency 64 bit, data acquisition 32 bit, AD 24 bit, arithmetic. Integrated RS232 for VIDEO extensometers. PC connection – Ethernet 10/100 Mbit, USB 2.0.

MEZERA

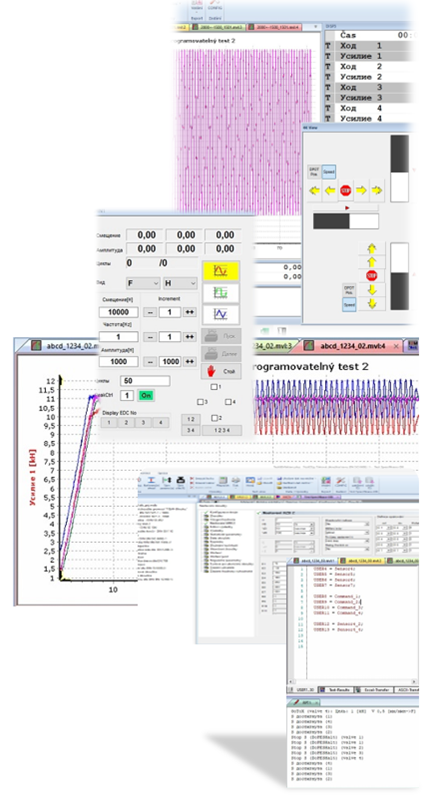

Test&Motion+ – DYNPACK Software

Intuitive software for long-term dynamic tests…

Test & Motion + – DYNPACK – intelligent, intuitive and powerful software that will help you increase productivity and testing quality in your test rooms and testing laboratories. You can streamline, refine, and accelerate your testing and adapt your testing environment to make it easy for operators to measure the mechanical properties of materials in a dynamic single-axis or multi-axis test mode with support for EN, ISO, DIN, ASTM, and GOST standards.

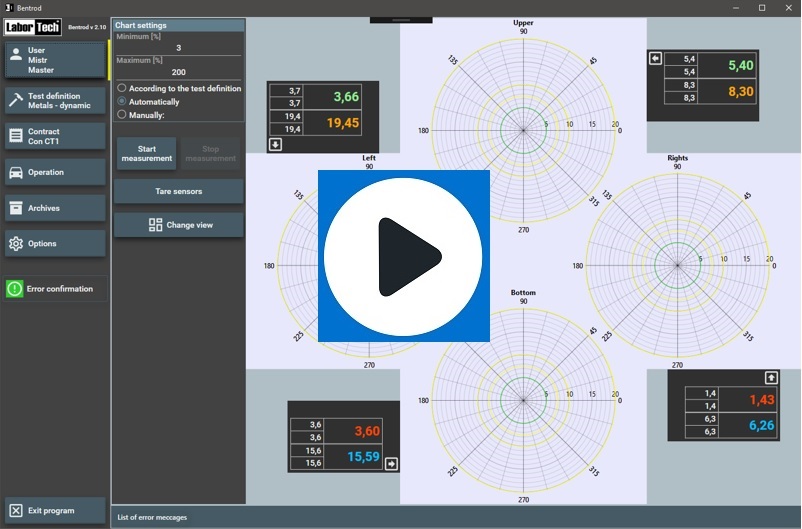

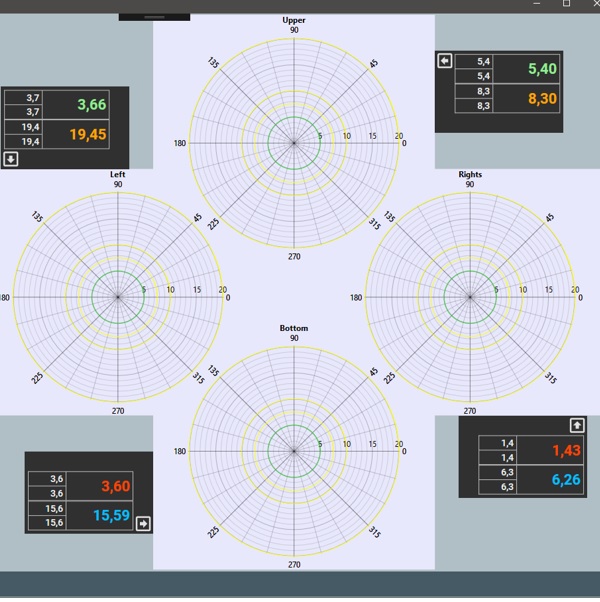

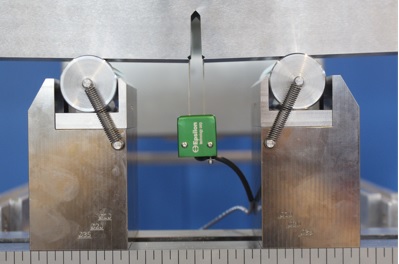

BENTROD system

A solution that can accurately and easily set up the X and Y system

BENTROD measuring and setting unit

LABORTECH biaxial load frames exhibit excellent rigidity and coaxiality, which minimizes bending stress to increase test accuracy and reduce data scatter. Proper coaxiality prevents off-axis bending stress, which can degrade the sample (sampling and production is very expensive) or the resulting data will be skewed and therefore unusable. BENTROD measuring and setting unit designed for evaluation and optimization of concentric and edge correction of misalignment (clamping) of clamping grips for static and dynamic testing machines according to ASTM E1012, GES400 (NADCAP), GE450 and ISOTC 164SC5WG11

Centering fixture CEDEROD 250- BIAXIAL

Designed for initial alignment of 4 grips, control verification of coaxiality and adjustment after replacement of components of load hydraulic units. Maximum machining and centering accuracy with precise center holes. Special adjusting cross made of material with temperature stabilization with a set of 64 semiconductor strain gauges for adjusting the X and Y axis. Adjustment in two axes, including the spherical surface, is performed using 8 Allen screws with fixation.

BENTRODTest – BIAXIAL

Visualization of 3 levels using R, G, B points

Choice of static or dynamic settings

Definition of standards according to the type of test, predefined standards

Adjustable chart scale: manual, automatic, database

Database backup, Archive of measured values

Print setup log

Integrated system calibration, etc.

VIDEO Extensometer EOX

accurate measurement, precise control and excellent analysis….

The lens is a key part of the entire measuring system

New advanced axial, transverse and biaxial video extensometer EOX using the latest digital image correlation technology thanks to the telecentric lens. This lens is a key component of the entire machine vision-driven measuring system: these lenses can truly take advantage of high-resolution detectors that capture images with exceptional fidelity, high accuracy and no optical distortion. Camera resolution – 5 Mpx, pixel size – 3.45 μm, camera connection – C-Mount. Special tripod – mechanical support system with fixed and safe mounting declares easy integration of the entire optical system into the biaxial machine.

DYNAMIC ALFA Software

Designed for initial alignment of 4 jaws, control verification of alignment and adjustment after replacement of components of load hydraulic units. Maximum machining and centering accuracy with precise center holes. Special adjusting cross made of material with temperature stabilization with a set of 64 semiconductor strain gauges for adjusting the X and Y axis. Adjustment in two axes, including the spherical surface, is performed using 8 Allen screws with fixation.