EP – Electromechanical dynamic testing machines

Electromechanical linear dynamic testing machines of EP series based on linear motor technology are designed for testing a wide range of materials and components in dynamic and static modes where oil-free and noiseless drive technology is preferred in the plastics, aerospace or medical industries with a maximum test frequency of 200Hz. All modifications we make to dynamic and fatigue test systems are designed so that the customer can fully rely on its function in high cycles, low cycle fatigue tests, crack propagation and growth, and other types of tests.

Download:

Download:

Download:

Download:

MEZERA

Key features of EP series

MEZERA

MEZERA

- The robust vertical table or stand design with adjustable crossbar has high rigidity, mechanical resistance and durability, guaranteeing 100% repeatability of results in small installations, oil-free and noiseless drive technology.

- High dynamic power at a frequency of up to 200H.

- Linear drive digital feedback controlled cooling system.

- Use in accordance with ASTM E466, ASTM E399, ASTM E606, ASTM E647, ISO 12106, DIN 50100, ISO 18489, ASTM F2193, ISO 14801, ASTM F1798, ASTM F1717 other standards.

- Adjustment of the cross member mechanically or fully electrically, including process monitoring.

- Integrated T-slot plate with special suspension absorbing up to 95% of machine vibrations.

- Guaranteed system of coaxiality in accordance with ASTM E 1012.

- Possibility of extension by a torsion system depending on the frequency and number of cycles.

- Test control by electro dynamic linear motor with the possibility of control in the power and position loop.

- Complete test evaluation and control is provided by Test & Motion material testing software – DYNPACK.

- Load cell in the upper crossbar working in the accuracy class according to EN ISO 7500-1, ASTM E4

- The EP series machines comply with all the above-mentioned EC directives on machinery and equipment and work in accordance with the new safety functions according to EN ISO 13850-SIL 1/PL.

- The machine is controlled by measuring and control electronics of the EDCi series with a sampling frequency of 10 kHz.

- Integration of special jaws for axial torsion tests or various jigs according to standards, etc.

- High-precision tests with temperature chamber or high-temperature furnace.

MEZERA

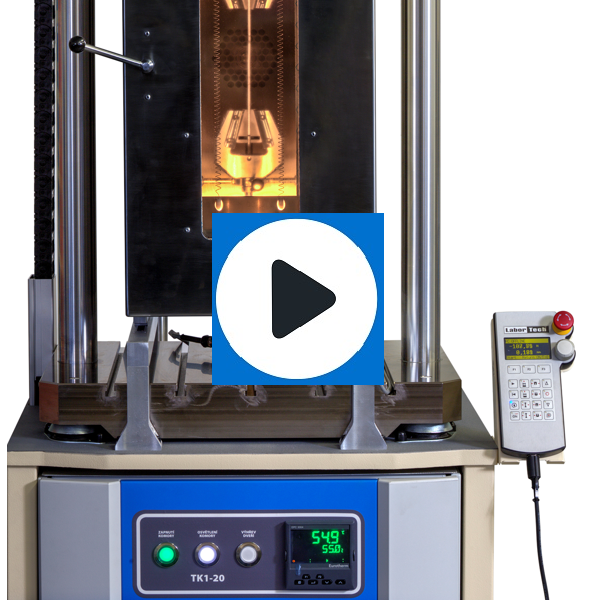

VIDEOS of EP ELECTRODYNAMIC TESTING MACHINE

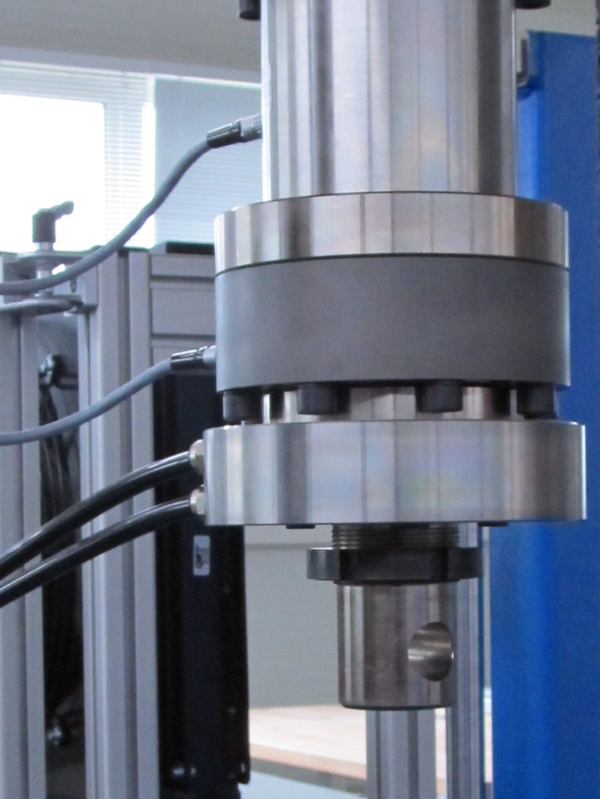

Axial test on electrodynamic testing machine EP

Testing of test sample using special lightweight gripss, with which it is possible to test up to a frequency of 200Hz.

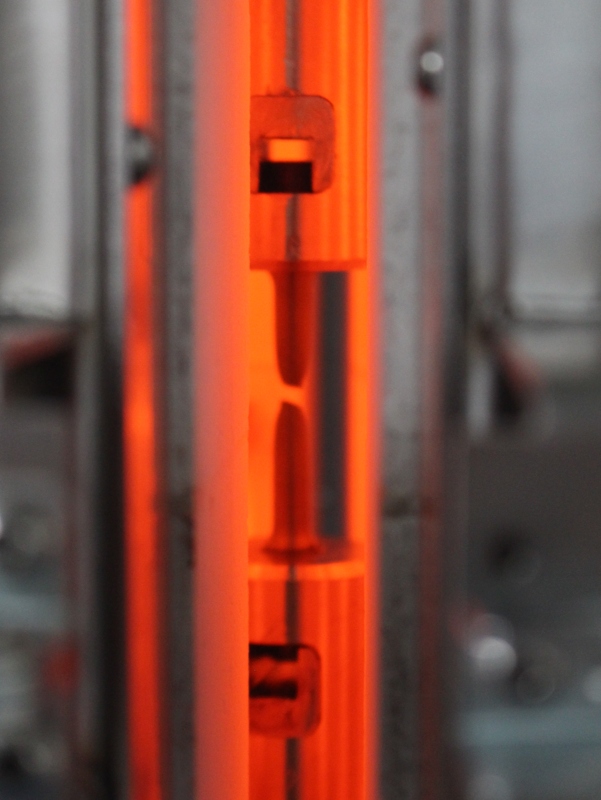

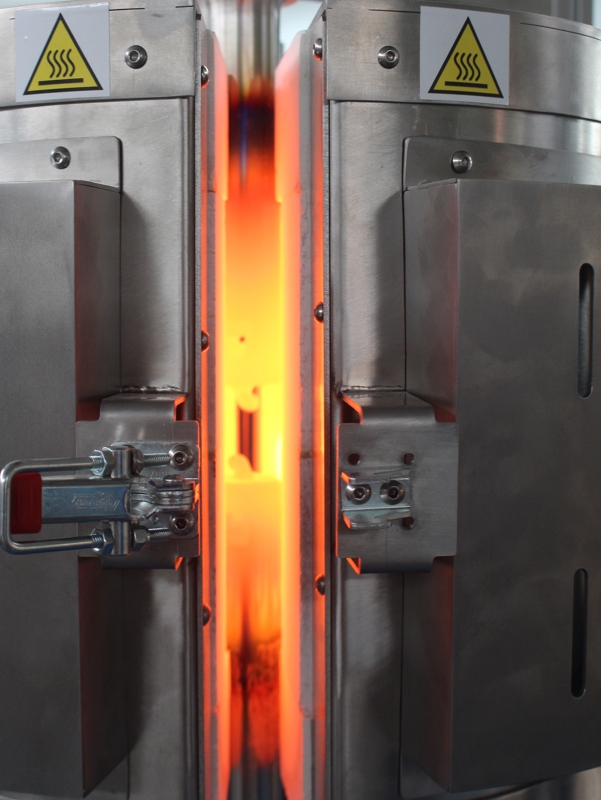

Removal of the test sample from the 350 ° C temperature chamber

Removal of a standardized sample from the temperature chamber after a dynamic test of 200Hz ± 3000N in accordance with EN ISO 6892-2.

MEZERA

Do you have questions about our products?

Feel free to contact our product experts.

We look forward to your interest.

–

MEZERA

TESTING ON LABTEST EP MACHINES WITH VARIOUS ACCESSORIES

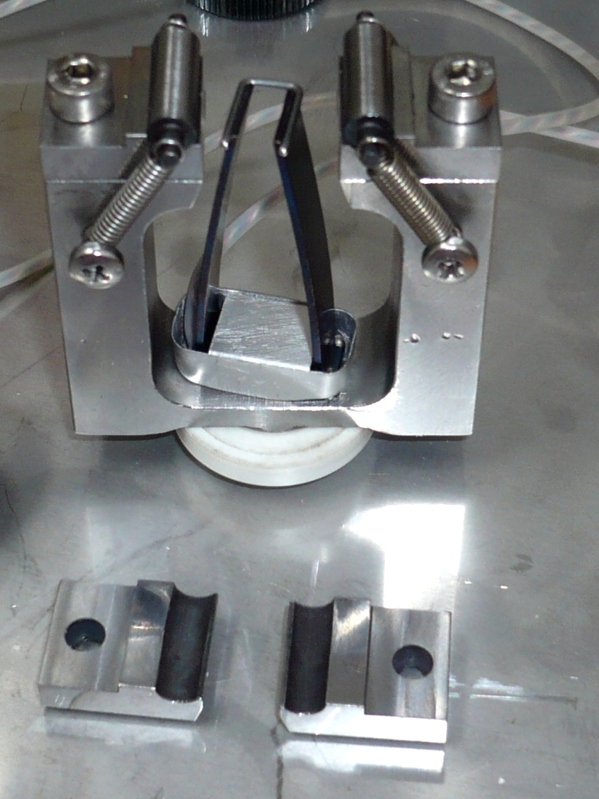

Test with various fixtures and clamping grips

Various types of clamping grips and test fixtures for fastening and dynamic testing of metals, carbon, plastics, laminates, etc. for dynamic tensile, compressive and bending tests according to EN 6892-1, ISO 12106, ASTM E606, DIN 50100, ASTM E399, ASTM E647, ASTM E466 etc.

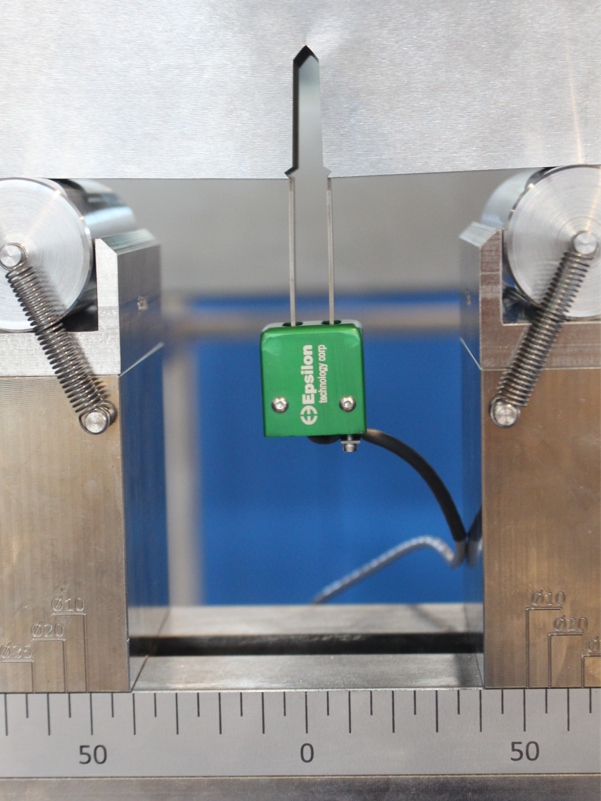

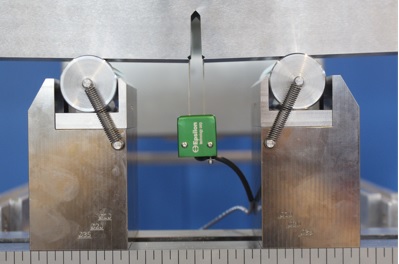

Tests with extensometers and measuring probes

Tensile test with extensometers in accordance with EN ISO 9513, EN 6892-1, ISO 12106, ASTM E606, DIN 50100, ASTM E399, ASTM E647, ASTM E466, etc.

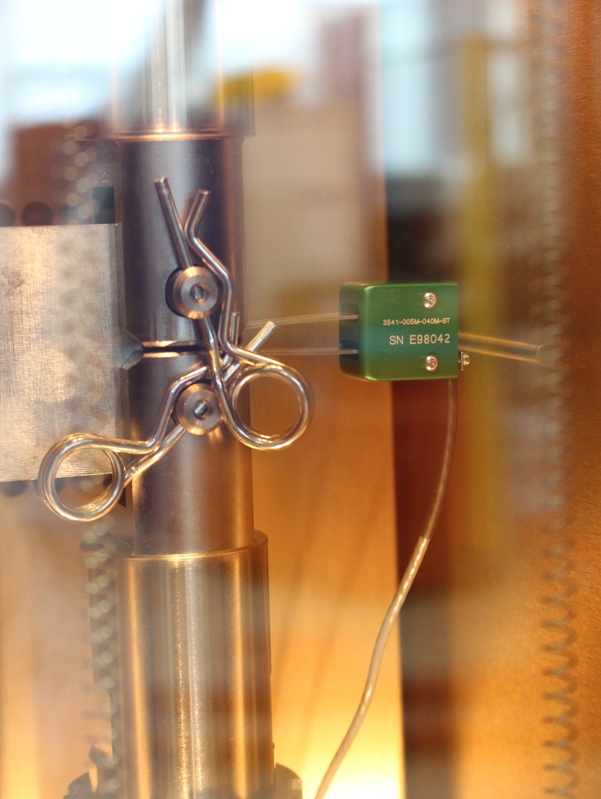

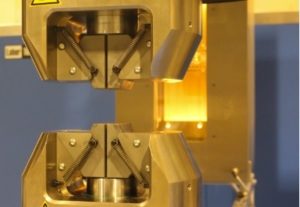

Test with high temperature furnace and temperature chamber

High temperature tensile and compressive dynamic tests according to ISO 6892-2 Method A1, EN 6892-1, ISO 12106, ASTM E606, DIN 50100, ASTM E399, ASTM E647, ASTM E466 etc.

MEZERA

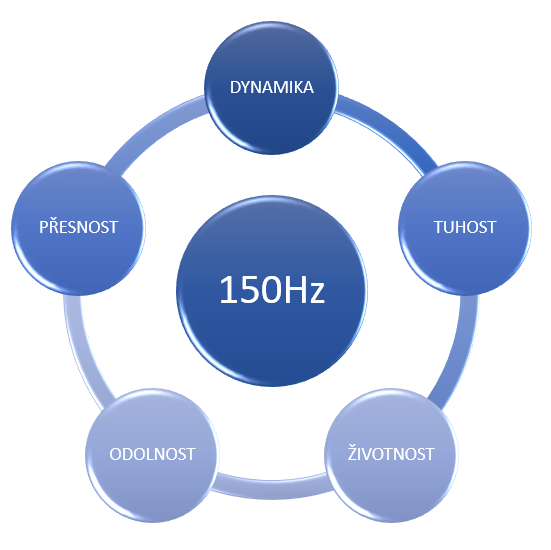

System properties of electromechanical linear dynamic testing machines of the EP series

Stiffness, precision and high dynamics with fully digital control…

Design

Advantages and features:

The robust vertical table or stand design with an adjustable crossbar has high rigidity, mechanical resistance and durability, guaranteeing 100% repeatability of results in small installations – 0.27 m² (machines up to 5000N).

The crossbarr can be adjusted mechanically or fully electrically, including process monitoring.

The integrated T-slot plate with special suspension at the base absorbs up to 95% of the machine’s vibrations.

DRIVE

Advantages and features:

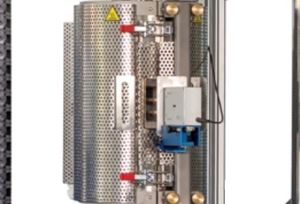

Specially designed compact oil-free linear actuator developed by LABORTECH with high dynamics, low moment of inertia at a stroke of 70 mm.

Low noise level at maximum power and maximum test frequency up to 200Hz.

Cooling is provided by controlled air circulation

Power supply of machines up to 3000N is single-phase at 230V.

ELECTRONICS

Advantages and features:

Řízení stroje je prováděno novou měřící a řídící elektronikou řady EDCi se vzorkovací frekvencí 10 kHz.

Rozlišovací úroveň analogových signálů ± 250.000 dílků (20 ms). Připojení k PC – Ethernet 10/100 Mbit, USB 2.0.

Ovládání a diagnostika stroje pomocí dálkového ovládače RMCi s LCD displejem.

Silový snímač s integrovaným snímačem zrychlení a digitální optický snímač prodloužení s možností rozšíření o kombinovaný snímač axiál / torze.

UNIVERSALITY

Advantages and features:

The great versatility of the EP series combined with the expansion of the machine with various accessories: test grips and special fixtures, temperature chambers and high-temperature furnaces, vessels and baths with saline solution, video extensometers, etc.

Extension by torsion testing up to ± 25Nm,

Possibility of integration of a force sensor in the lower or upper part of the machine, extension of the working space by 410 mm, etc.

SOFTWARE

Advantages and features:

Intelligent, intuitive and powerful DYNAPACK software designed for static and dynamic applications.

It will help you increase the productivity and quality of testing in your test rooms and testing laboratories by using different modules for each test standard.

SAFETY

Advantages and features:

Based on their concept and construction, LABORTECH machines comply with all the following EC directives on machinery and equipment and standards: EN ISO 12100: 2011, EN ISO 14120: 2017, EN ISO 60204-1 ed.3, EN ISO 13850: 2017, EN 61000 -6-2 ed. 3, EN 614-1 + A1: 2009 etc.

Safe setting mode according to EN 60204-1 via test speed.

MEZERA

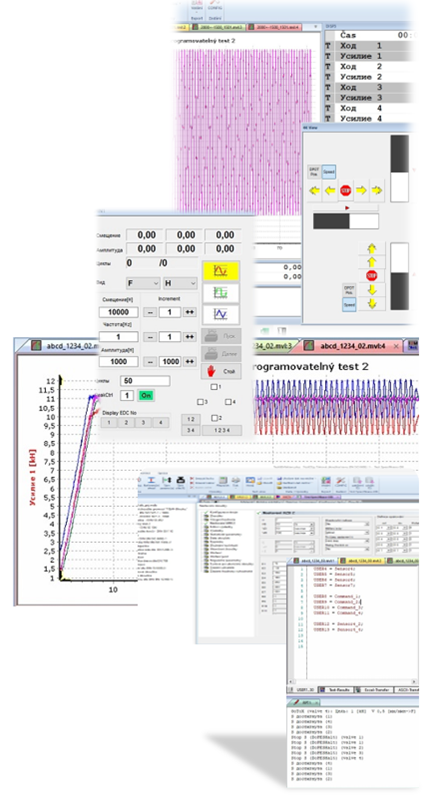

Test&Motion+ – DYNPACK Software

Intuitive software for long-term dynamic tests…

Test & Motion + – DYNPACK – intelligent, intuitive and powerful software that will help you increase productivity and testing quality in your test rooms and testing laboratories. You can streamline, refine, and accelerate your testing and adapt your testing environment to make it easy for operators to measure the mechanical properties of materials in a dynamic single-axis or multi-axis test mode with support for EN, ISO, DIN, ASTM, and GOST standards.

BENTROD system

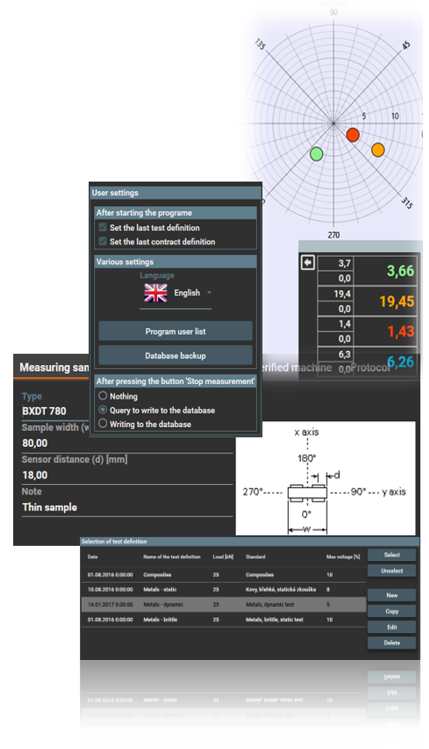

A solution that can precisely and easily set the coaxiality of a dynamic system…

LABORTECH EP series test load frames exhibit excellent rigidity and coaxiality, which minimizes bending stress to increase test accuracy and reduce data scatter. Proper coaxiality prevents off-axis bending stress, which can degrade the sample (sampling and production is very expensive) or the resulting data will be skewed and therefore unusable. BENTROD measuring and setting unit designed for evaluation and optimization of concentric and edge correction of misalignment (clamping) of clamping jaws for static and dynamic testing machines according to ASTM E1012, GES400 (NADCAP), GE450 and ISOTC 164SC5WG11

CEDEROD centering fixture

- Designed for initial coaxiality of grips and fixtures, control verification of coaxiality and adjustment after replacement of components of load hydraulic units.

- Maximum machining and centering accuracy with precise center holes.

- Special adjustment sample made of material with temperature stabilization with a set of 32 semiconductor strain gauges for adjusting the X axis.

- Adjustment in two axes, including the spherical surface, is performed using 8 Allen screws with fixation.

Basic features of BENTRODTest – axis software

- Visualization of 3 levels using R, G, B points

- Choice of static or dynamic settings

- Definition of standards according to the type of test, predefined standards

- Adjustable chart scale: manual, automatic, database

- Database backup, Archive of measured values

- Printing of Set up protocol

- Integrated system calibration, etc.

MEZERA

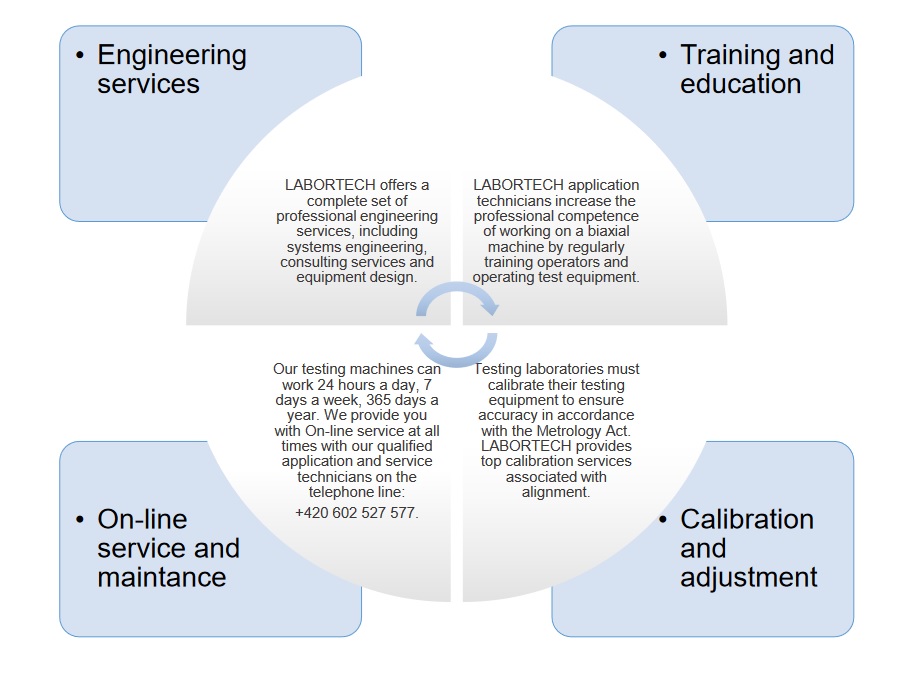

Why buy EP series machines from LABORTECH?

Because we offer everything from A to Z, ie. from development to implementation…

Inženýrské služby: LABORTECH nabízí kompletní sadu profesionálních inženýrských služeb, včetně systémového inženýrství, konzultačních služeb při zkouškách a návrhů zařízení.

On-line servis a údržba: Naše zkušební stroje můžou pracovat 24 hodin denně, 7 dní v týdnu, 365 dní v roce. Po celou dobu Vám poskytujeme On-line servis našimi kvalifikovanými aplikačními a servisními techniky na telefonní lince +420 602 527 577.

Školení a výcvik :Aplikační technici firmy LABORTECH pravidelným školením operátorů a obsluhy zkušebního zařízení zvyšují odbornou způsobilost práce na elektro dynamických strojích

Kalibrace a nastavení: Zkušební laboratoře musí kalibrovat svá zkušební zařízení, aby byla zajištěna přesnost v souladu se zákonem o metrologii. LABORTECH poskytuje špičkové, kalibrační v souladu s EN ISO normami.