C.X – SPECIAL CREEP TESTING MACHINES FOR LONG-TERM TESTS – Atypical

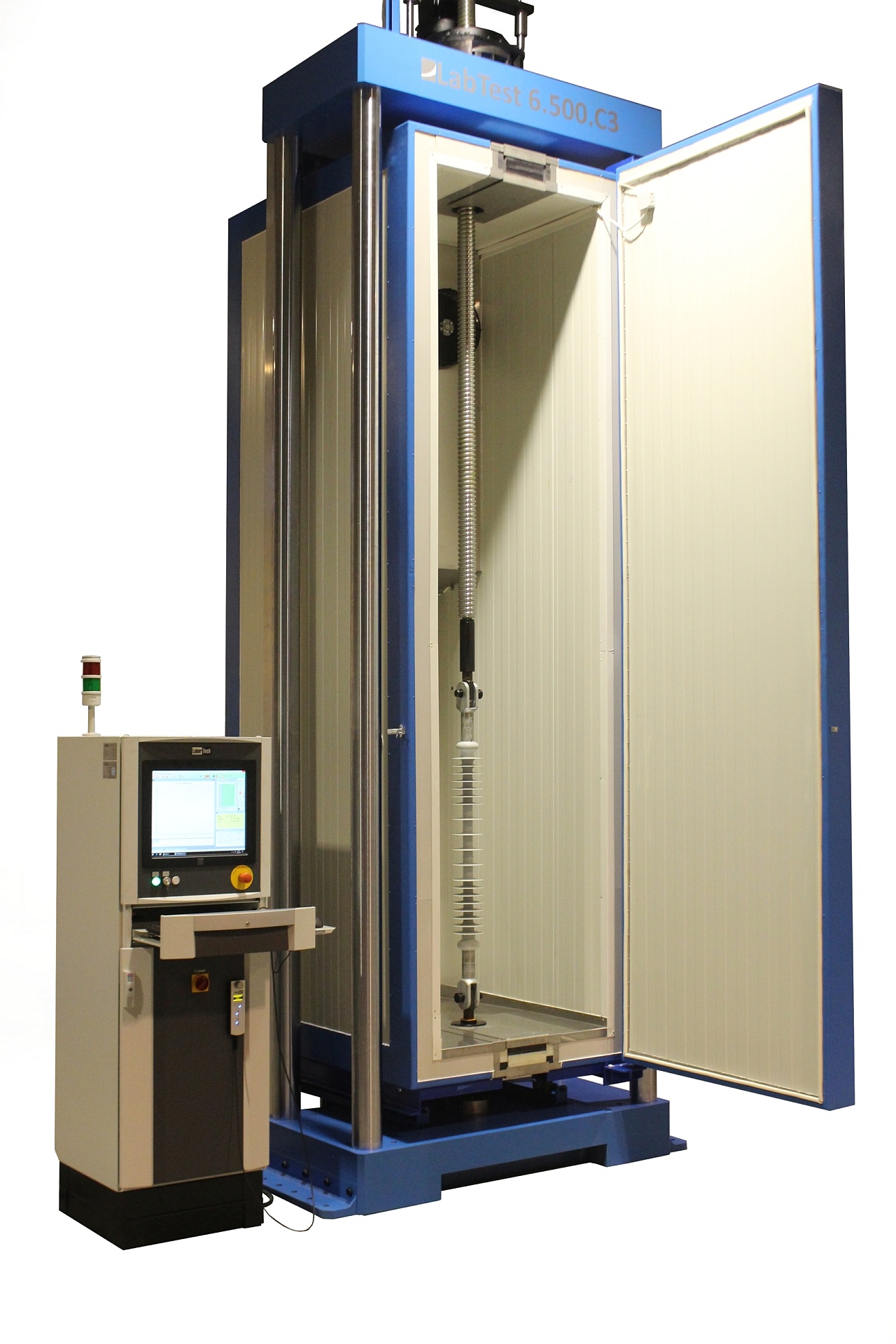

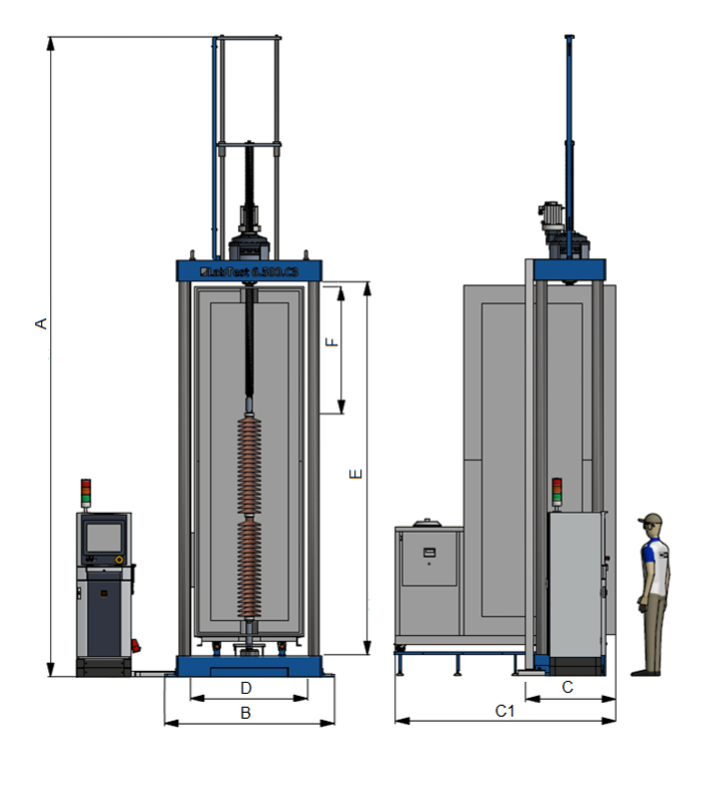

Electromechanical testing machines of the C.x series CREEP in a vertical four-column design up to 500kN maintaining a constant load by means of a central loading mechanism consisting of a central ball screw and a special mounting of a precision cycloidal gearbox with an integrated AC servo drive. These machines are intended for performing long-term low-cycle fatigue in the I quadrant up to a frequency of 2 Hz, determining crack propagation, creep, stress relaxation in the material, corrosion resistance, etc.

Download:

MEZERA

Key features of the C.x special series

Accuracy, alignment and service life, these are the parameters in the standard

MEZERA

Types of tests and standards

- Electromechanical machine for testing the creep of materials at ambient and minus and plus temperatures

- Types of tests: fatigue tests in the tensile range, creep test at slow speeds, ductility and relaxation tests, classical creep tests, deformation modeling, crack growth and propagation tests, hydrogen embrittlement determination, tests with continuous control of force and temperature

- Types of test standards: EN 2002-005, ISO 204, ASTM E1457, ASTM E139, ASTM F519, ASTM G129

- Only tensile tests on oversized specimens can be performed with this testing machine

- Any load application with controlled force.

Machine construction

- Vertical stand design with high rigidity, guaranteed mechanical alignment and service life.

- Loading using a free-play ball screw and a special bearing of a precision cycloidal gearbox with an integrated AC servo drive with a load life of more than 10,000 hours.

- Machine construction as defined for testing with EN 2002-005, ISO 204, ASTM E1457, ASTM E139, ASTM F519, ASTM G129

- Durable vibration pads to prevent the transmission of vibrations.

- Automatic termination of the test after breaking the samples with the possibility to set the criterion.

- Accuracy class 1 according to EN ISO 7500-1 – 0.3 to 100% of nominal load.

Machine operation and machine control

- Quiet and precise AC servo drive with low noise, high resolution with control in force and position loop.

- Based on their concept and construction, LABORTECH machines comply with all the EC directives on machinery and equipment and standards: EN ISO 12100:2011, EN ISO 14120:2017, EN ISO 60204-1 ed.3, EN ISO 13850:2017, EN 61000 -6-2 ed. 3, EN 614-1+A1:2009, etc.

- Automatic identification of sensors working in the accuracy class according to EN ISO 7500-1, ASTM E4 with the possibility of linearization.

- The machine is controlled by measuring and control electronics of the EDCi series with a sampling frequency of 2.5 or 10 kHz. Resolution level of analog signals ± 250,000 parts (20 ms). Connection to PC – Ethernet 10/100 Mbit, USB 2.0.

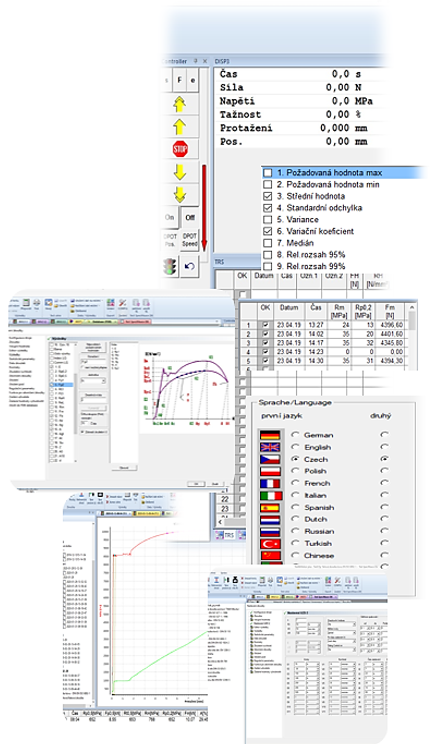

- Complete evaluation and control of the test is provided by the material testing software Test&Motion.

- Machine control and diagnostics using the RMCi remote control with LCD display.

Temperature chamber

- Special heating coils and cooling with the help of a dual compressor to a temperature of -40°C for long-term tests with separate thermocouples = temperature homogeneity of the field.

- SIEMENS TC-22 temperature controller with precise control built into the temperature chamber.

- Wide temperature range with tolerances better than ISO 204 and ASTM E139.

- One, two or three thermocouples – depending on sample length, material and shape.

Control software

- Test&Motion+ – BASIC – intelligent, intuitive and powerful software that will help you to increase the productivity and quality of testing in your testing and testing laboratories.

- Streamline and refine your test execution and customize your testing environment to make it easy for operators to measure the mechanical properties of materials in tension, compression and bending with support for EN, ISO, DIN, ASTM and GOST standards.

- Optional modules: closed-loop force control, stress- and strain-controlled creep, stress relaxation tests, user-defined load cycles UZD 2

- Ease of use when performing the test and evaluating the test result, including the integrated temperature control of the TC 22 high-temperature controller

- Well-secured data archiving using the UPC unit

Safety

- LABORTECH machines, based on their concept and construction, correspond to all the mentioned EC directives on machinery and equipment.

- Only the most modern safety techniques and proven industrial components working in accordance with the standards are used: EN ISO 12100:2011, EN ISO 14120:2017, EN ISO 60204-1 ed.3, EN ISO 13850:2017, EN 61000-6-2 ed . 3, EN 614-1+A1:2009, etc.

MEZERA

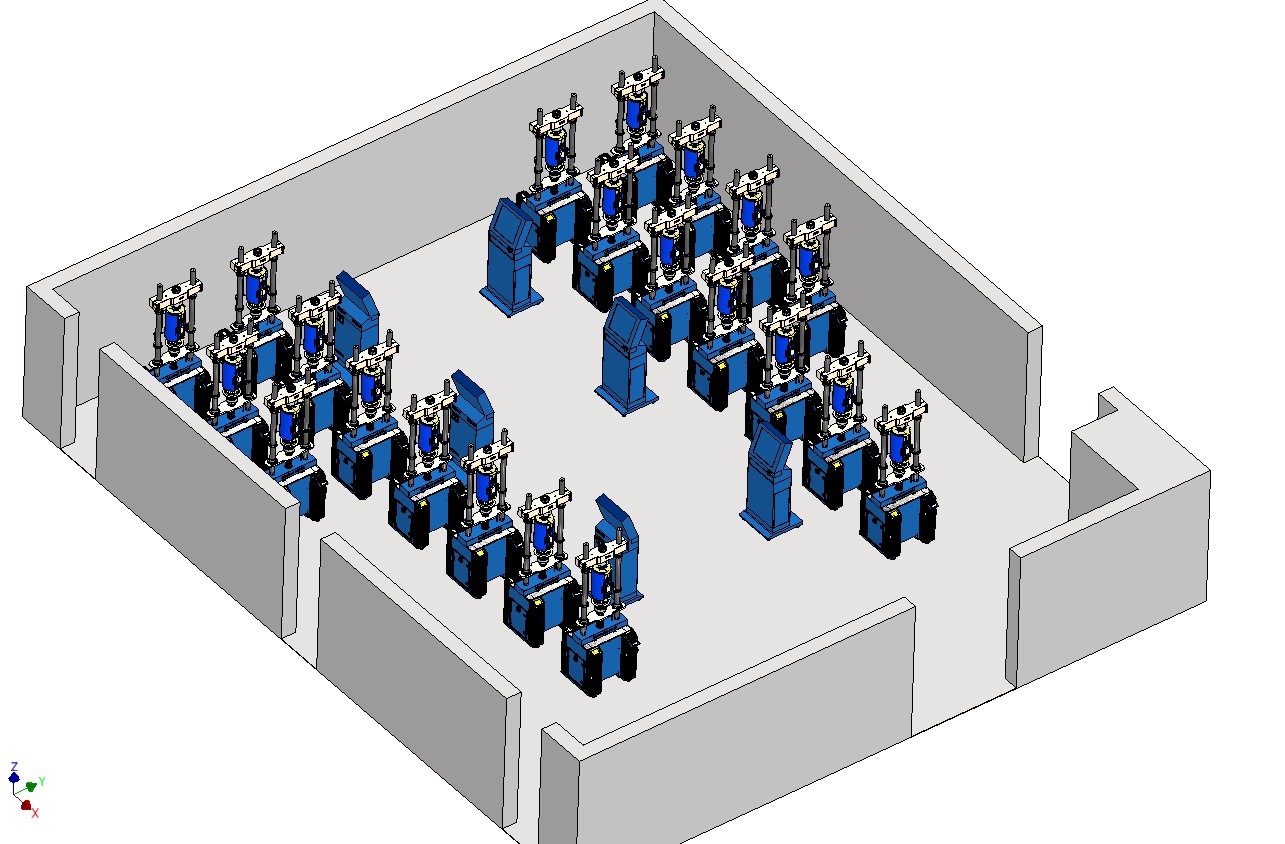

TESTS ON SPECIAL CREEPTest Cx WITH DIFFERENT ACCESSORIES

With our range of accessories, you can cover all tests…

MEZERA

Trial preparations

Clamping and centering devices intended for long-term tests with devices for high-temperature furnaces.

Materials used: Allooy, Haynes, MAR

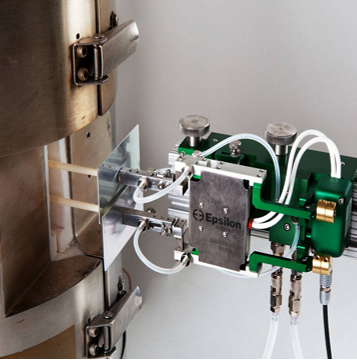

Mechanical extensometers

Extensometers for high-temperature furnaces for long-term tests – contact up to 1600°C

Resolution EN ISO 9513: Class 0.5 ASTME83-10: Class 0.5

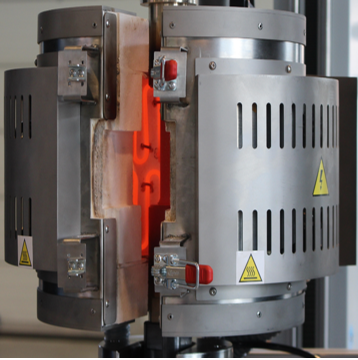

High temperature furnaces

High temperature furnaces in the temperature range from 20 to 2000°C with tolerances better than ISO 204 and ASTM E139.

SIEMENS TC-22 temperature control for up to 6 thermocouples.

Video extensometers

VIDEO extensometers for high-temperature furnaces for long-term tests – non-contact up to 1400°C.

Resolution EN ISO 9513: Class 0.2 ASTME83-10: Class A

MEZERA

MEZERA

Do you have questions about our products?

Feel free to contact our product experts.

We look forward to your interest.

–

MEZERA

TABLE OF TECHNICAL PARAMETERS SPECIAL Cx series

- Units

- –

- kN

- mm/h-mm/min

- kN

- um

- mm

- mm

- mm

- mm

- mm

- mm

- mm

- mm

- kg

- VA

- 6.500C.3

- 1.03020319

- 500

- 0,00001 – 50

- 1,5 až 500kN

- 0,0023

- ± 0,01

- 7105

- 1600

- 935

- 2635

- 4120

- 1300

- 60 až 2075

- 7000

- 8000