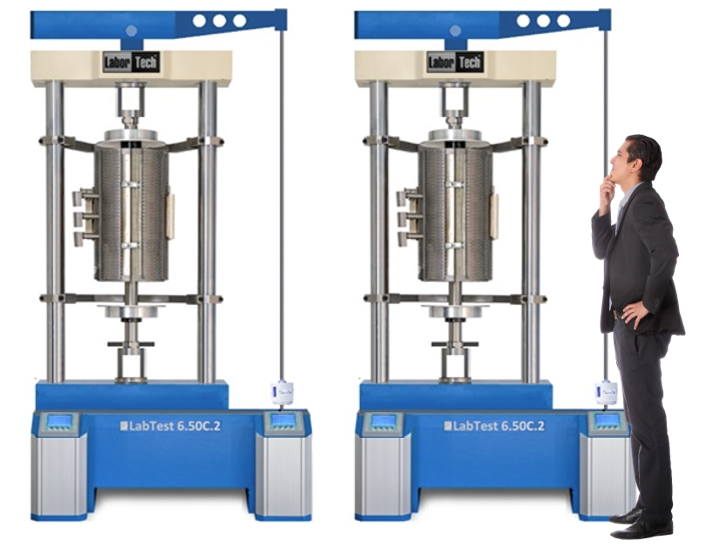

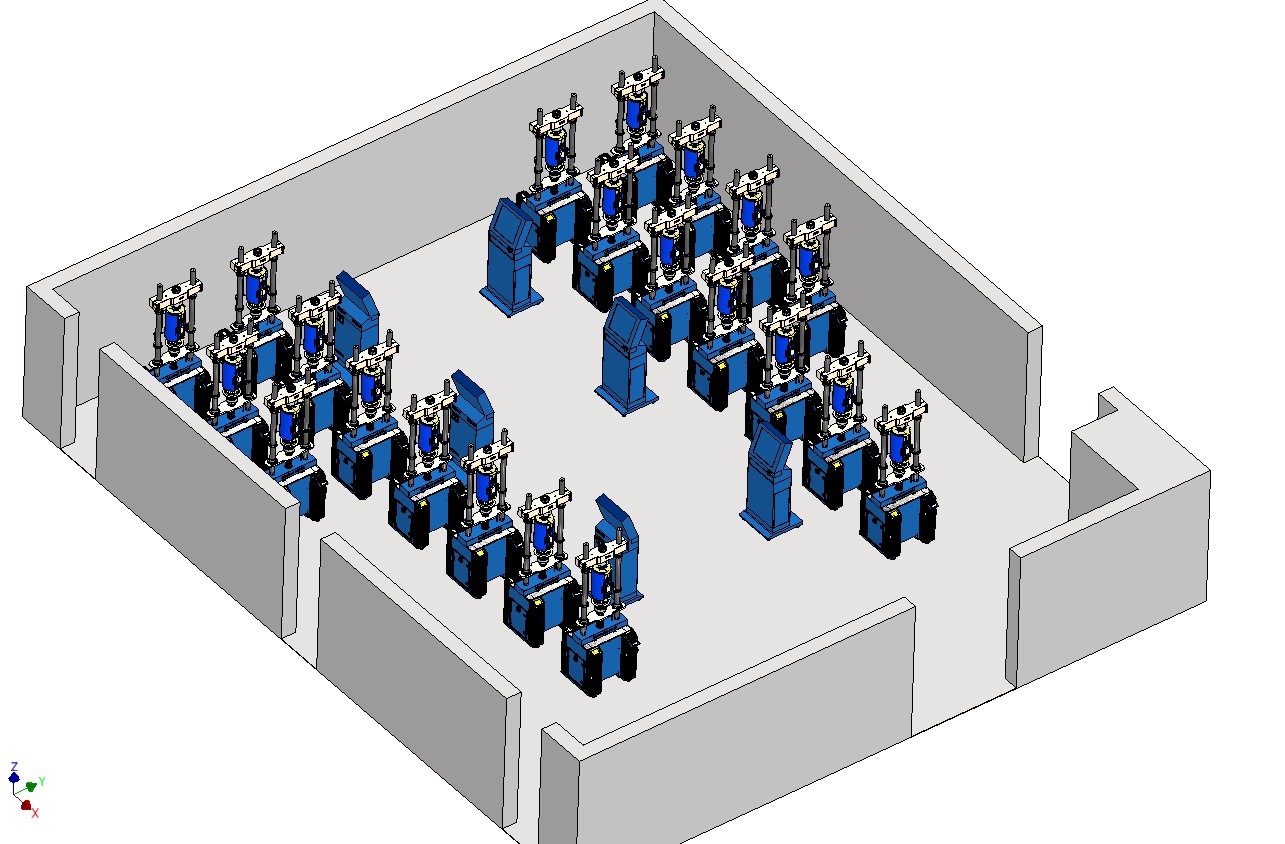

C.2 – CREEP TESTING MACHINES WITH LEVER SPRING MECHANISM

The LABORTECH company offers testing machines for long-term C.2 tests, where a constant load is exerted by a lever mechanism by means of a spring and a control force sensor. All modifications of CREEP test systems C.2 manufactured by us are designed so that the customer can fully rely on its function and accuracy under long-term constant loading (material flow) with force or stress, including elongation and at a constant homogeneous temperature in a high temperature furnace with reliable declaration of results. even after 100,000 hours of continuous loading.

Download:

MEZERA

Key features of the C.2 series

Accuracy, coaxiality and durability are the parameters in the standard

MEZERA

Types of tests and standards

- Material testing machine for classical creep tests with constant gravitational force.

- Types of tests: crack growth / expansion tests, tear creep tests, rupture tests, classical creep tests.

- Types of test standards: ISO 204, ASTM E139, EN 2002-005, ASTM E1457.

- Any load application with controlled force.

Machine design

- Vertical stand design with high rigidity, guaranteed mechanical alignment and durability.

- Constant load using a lever mechanism, weights and gravitational force for more than 100,000 hours.

- Machine construction in accordance with EN ISO 204, ASTM E 292 and ASTM E139, GOST 10145, GOST 3248.

- Durable vibrating pads to prevent the transmission of vibrations.

- Automatic termination of the test after rupture of samples.

- Automatic leveling of the lever mechanism to the horizontal position.

- Accuracy class 1 according to ISO 7500-2 -4 to 100% of rated load.

Machine operation and machine control

- LCD SIEMENS integrated into the machine frame, easy to touch, comfort of the machine at a very high level.

- The machine is controlled by measuring and control electronics SIEMENS S7-1200.

- Sampling frequency 1000Hz. Resolution level of analog signals ± 32,000 divisions.

- PC connection – communication via Modbus TCP.

- Připojení teplotního regulátoru SIEMENS TC-22 přes Modbus RTU.

- Integrated UPC unit to cover electrical outages.

Axial coaxiality

- Coaxiality set according to ASTM E1012.

- Cross cutting edges contribute to axial alignment according to the requirements of ISO 204, ASTM E292, ASTM E139 and NADCAP.

- Articulated clamping (using cutting edges) in two places.

- System set by BENTROD unit – evaluation and optimization of concentric and edge alignment correction.

High temperature furnace

- Special heating coils for long-term tests with separate thermocouples = field temperature homogeneity.

- SIEMENS TC-22 temperature controller with precise control built into the machine frame.

- Wide temperature range with tolerances better than ISO 204 and ASTM E139.

- One, two or three thermocouples – depending on sample length, material and shape.

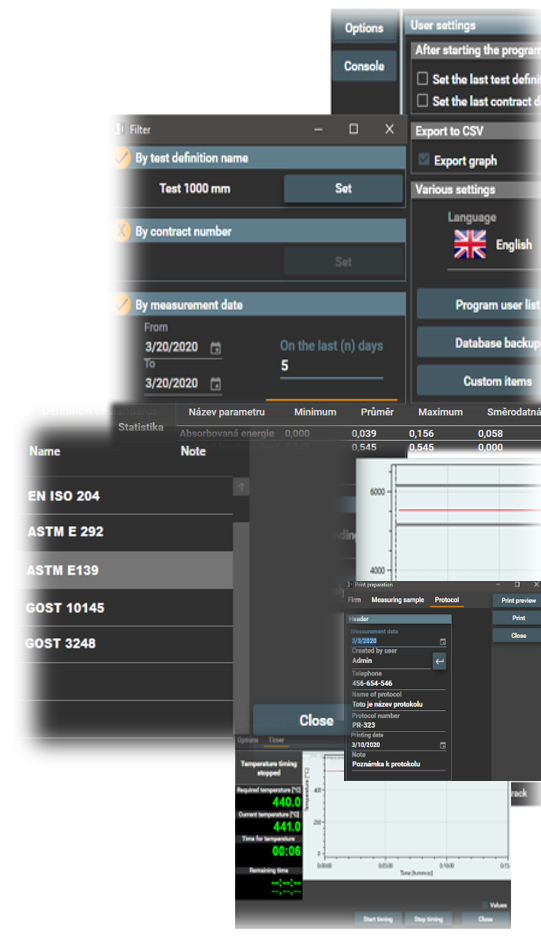

Control software

- The integrated intuitive LOTETest test software ensures machine control (gradual release of weights).

- Data collection and display of measured values from the force channel (if a force sensor is included), the elongation channel and the temperature on the sample as a function of time.

- CREEPTest software serves as a higher form of data collection, database storage, generation of own methods, etc.

Safety

- Based on their concept and construction, LABORTECH machines comply with all the above-mentioned EC directives on machinery and equipment.

- Only state-of-the-art safety techniques and proven industrial components working in accordance with the following standards are used: EN ISO 12100: 2011, EN ISO 14120: 2017, EN ISO 60204-1 ed.3, EN ISO 13850: 2017, EN 61000-6-2 ed . 3, EN 614-1 + A1: 2009 etc.

MEZERA

CREEP TESTS C.2 WITH VARIOUS ACCESSORIES

With our range of accessories you will cover all tests…

MEZERA

Testing fixtures

Clamping and centering jigs designed for long-term tests with jigs for high-temperature furnaces. high-temperature high-temperature high-

Materials used: Allooy, Haynes, MAR

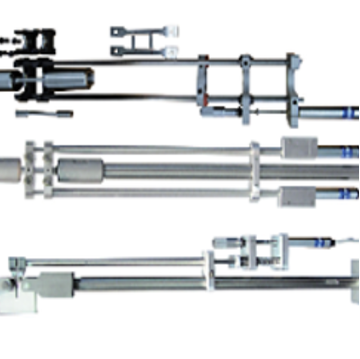

Mechanical extensometers

Extensometers for high-temperature furnaces for long-term tests contact up to 1600 °C. high-temperaturehigh-temperaturehigh- temperature

ISO9513 resolution: Class 0.5 ASTME83-10: Class 0.5

Video extensometers

VIDEO extensometers for high-temperature furnaces for long-term tests – non-contact up to 1400 ° C. high-temperature high-temperature high

SO9513 Resolution: Class 0.2 ASTME83-10: Class A

High temperature furnaces

HTF in the temperature range from 200 to 1600 ° C with tolerances better than ISO 204, ASTM E139

Temperature control SIEMENS TC-22 for up to 6 thermocouples.

MEZERA

MEZERA

Do you have questions about our products?

Feel free to contact our product experts.

We look forward to your interest.

–

MEZERA

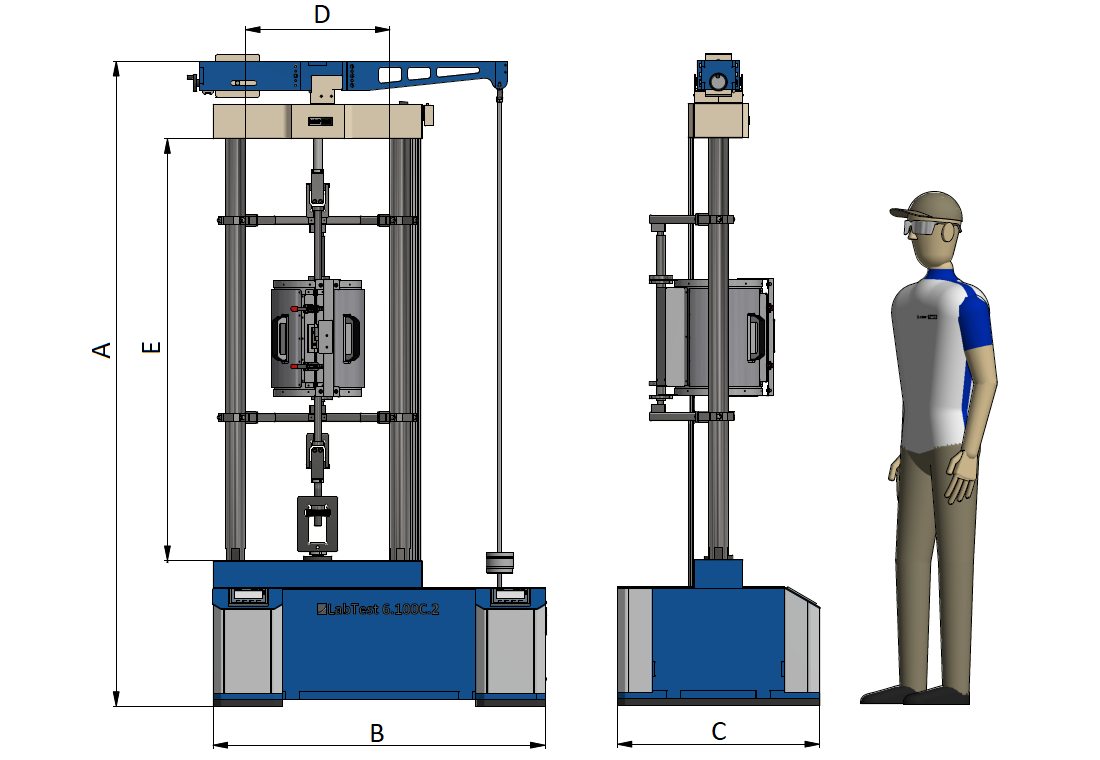

CHART OF TECHNICAL PARAMETERS series C.2

- Technical data

- Product code

- Maximum load

- Leverage ratio

- Machine dimensions

- Machine height – A

- Machine width – B

- Machine depth – C

- Space height – E*

- Testspace width – D

- Machine weight

- Test speed

- Max. stroke

- Measurement accuracy

- Units

- –

- kN

- –

- –

- mm

- mm

- mm

- mm

- mm

- kg

- mm/min

- mm

- –

- 6.10C.2

- 1.03020319

- 10

- 1:20

- –

- 2130

- 1150

- 700

- 1460

- 520

- 590

- 50

- 150

- ISO 7500-1

- 6.30C.2

- 1.03020019

- 30

- 1:20

- –

- 2280

- 1150

- 700

- 1460

- 500

- 665

- 50

- 150

- A class of accuracy 1

- 6.50C.2

- 1.03020119

- 50

- 1:20

- –

- 2280

- 1150

- 700

- 1460

- 500

- 665

- 50

- 150

- 0,3 to 100%

- 6.100C.2

- 1.03020219

- 100

- 1:20

- –

- 2280

- 1150

- 700

- 1460

- 500

- 665

- 30

- 150

- rated load