LABORTECH: Hysteresis Analysis in Tensile Testing According to ISO 6892-1:2019

Within tensile testing performed in accordance with ISO 6892-1 (2019 edition), the standard defines monotonic uniaxial loading up to fracture. Cyclic loading and evaluation of hysteresis loops are not specified as standard assessment parameters.

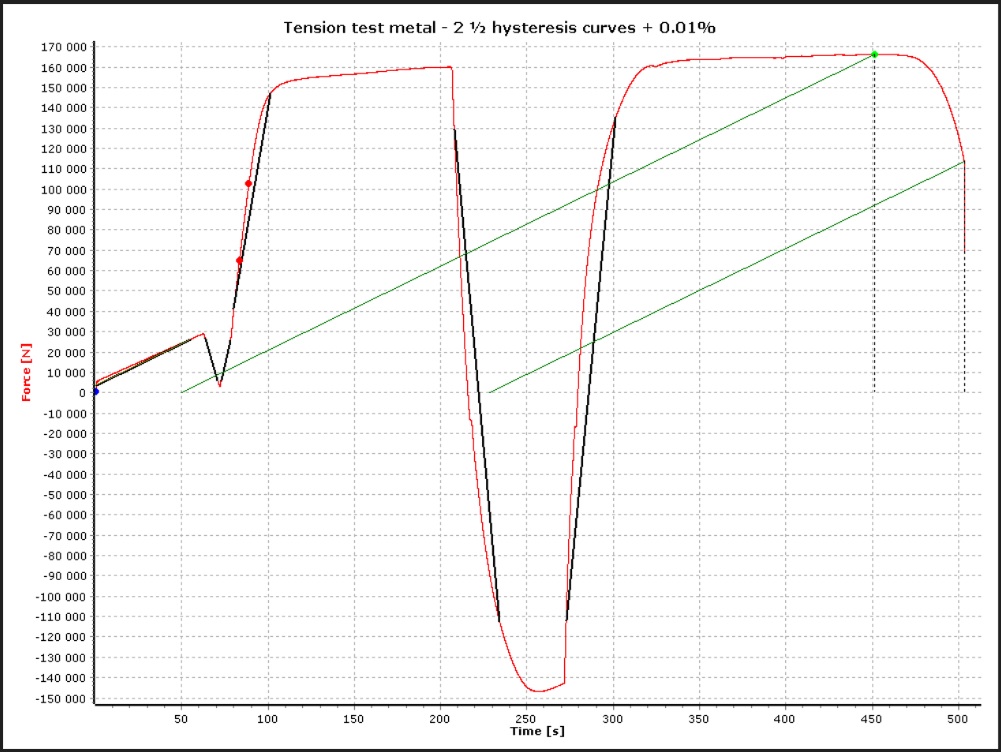

However, during the determination of the modulus of elasticity E (Clause 13), the standard allows stabilization of the measuring system and verification of the linear elastic region. In practice, this may involve a short controlled unloading followed by reloading, resulting in a small hysteresis loop. Although this loop is not subject to normative evaluation, it provides valuable insight into initial microplasticity, material stability, and stiffness changes during first loading.

This extended evaluation approach is particularly beneficial when testing high-strength and special materials used in demanding applications, such as the defense industry, where structures are exposed to high pressure and variable stress conditions.

The methodology with controlled unloading can be fully implemented on all LabTest E.3, E.4, and H.2 series testing machines manufactured by LABORTECH. Thanks to precise strain control and advanced software evaluation, detailed analysis of elastic response and early-stage material behavior can be achieved.

This extended tensile testing approach represents another step by LABORTECH toward deeper and technically advanced material characterization while remaining within the normative framework of ISO 6892-1.

TEAM LABORTECH

Leave a Reply

Want to join the discussion?Feel free to contribute!