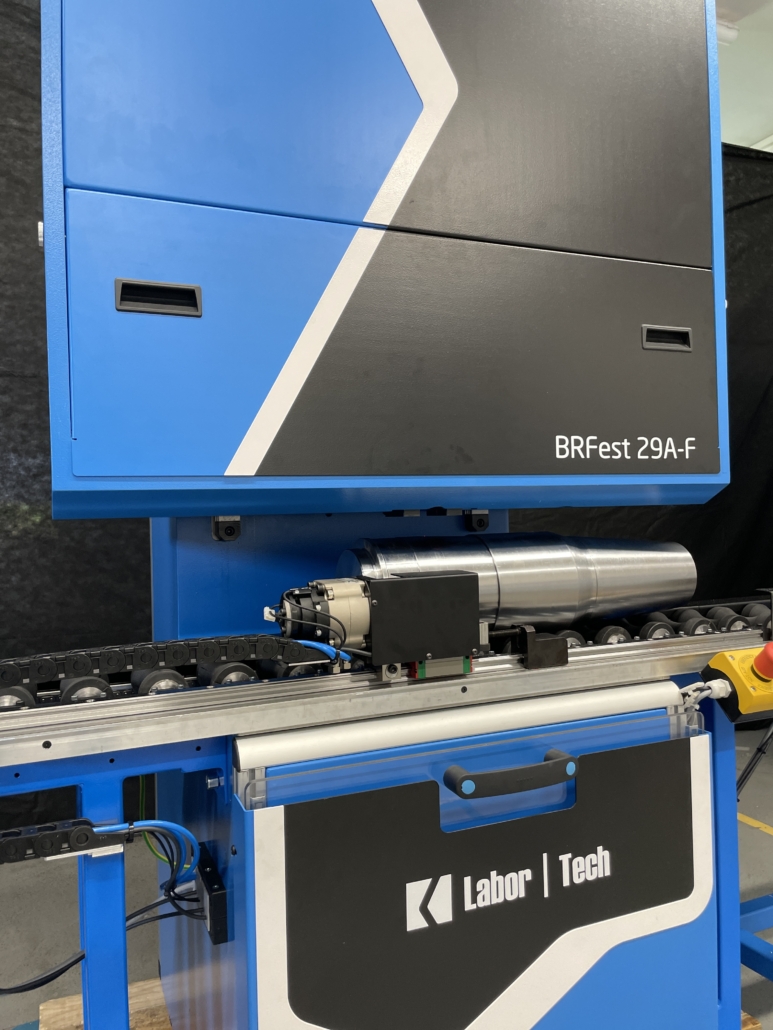

New Generation of Automatic Hardness Testers BRFest 29A-F – The Power of Precision in Every Indentation

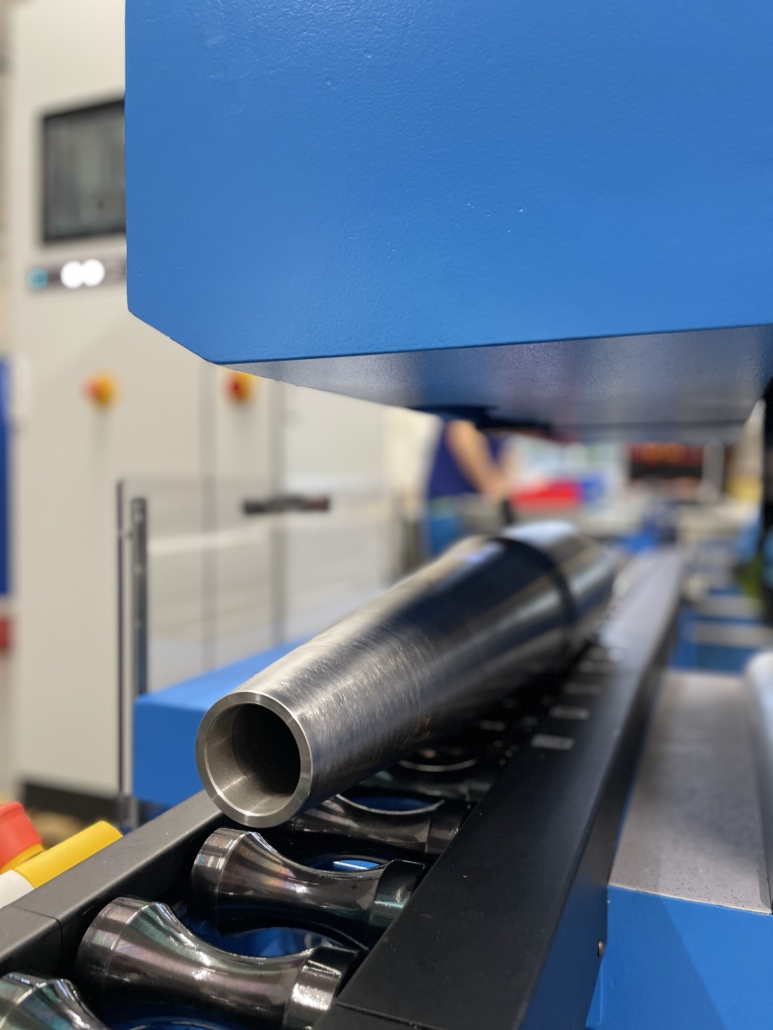

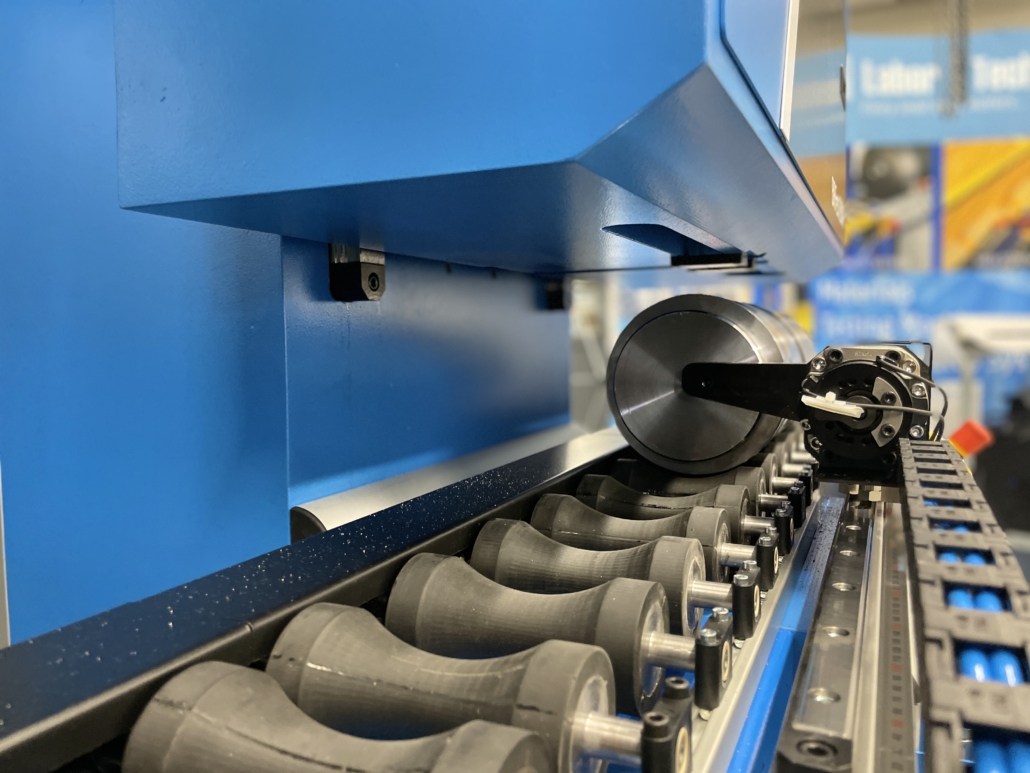

LABORTECH introduces the brand-new series of automatic hardness testers BRFest 29A-F, designed for highly efficient and precise hardness measurement using the Brinell or Vickers method. These intelligent systems push the boundaries of automated testing – from automatic surface preparation for indentation (spot milling) and loading up to 29,400 N, to fully automatic evaluation of results including database storage or automatic sample marking.

Thanks to their modular design, the BRFest 29A-F series offers exceptional versatility – it can operate as a stand-alone hardness tester, be integrated into a conveyor system (x-SLOB), or form part of a robotic workstation X-RUNNER, with the option of manual or automatic positioning of the tested specimen.

The BRFest 29A-F model is specifically developed for testing standard and geometrically complex parts (such as hubs and cartridges) in fully automatic mode, featuring a patented universal clamping system.

The result?

Maximum precision, operator comfort, outstanding stability, and testing speed – all combined in one device.

BRFest 29A-F – a new dimension of automated hardness testing.

TEAM LABORTECH

Leave a Reply

Want to join the discussion?Feel free to contribute!