Contact

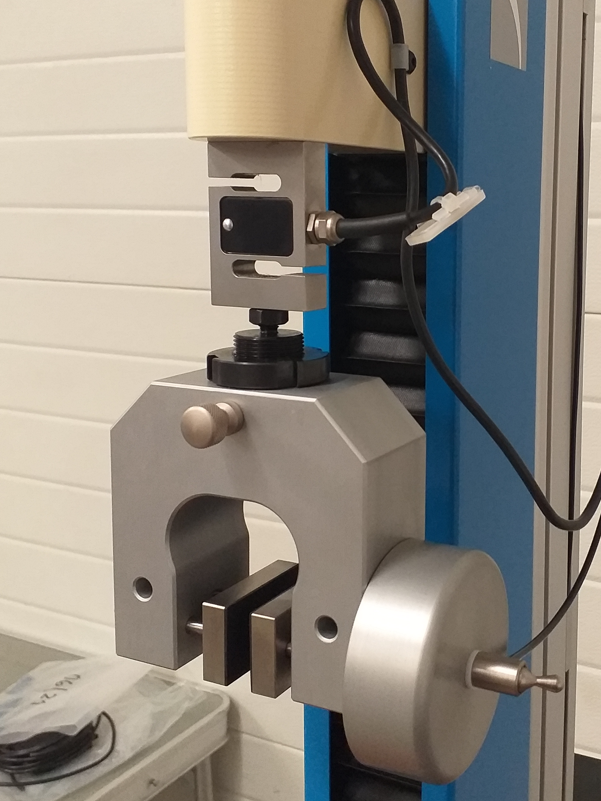

Force transducers for static and dynamic tests

Are you testing statically or dynamically? We know what you are measuring – and we have a solution for you without compromise…

Force transducers for static and dynamic tests

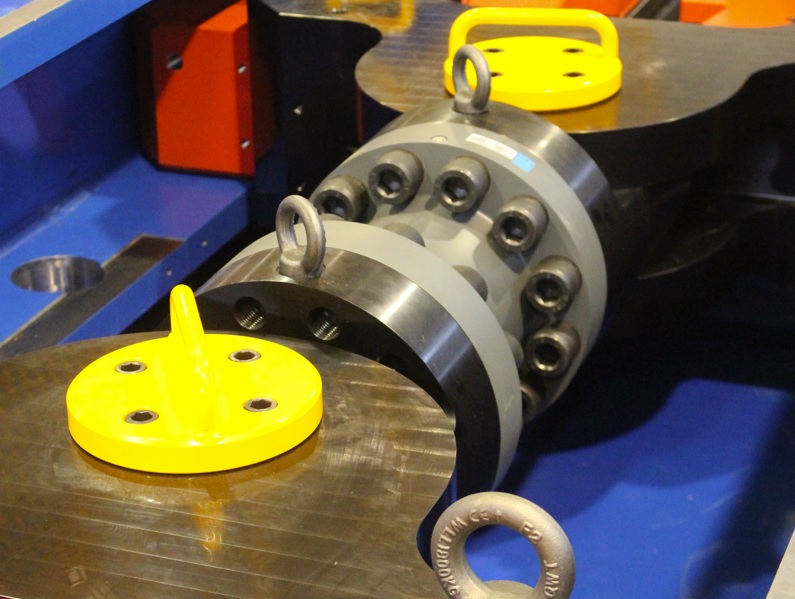

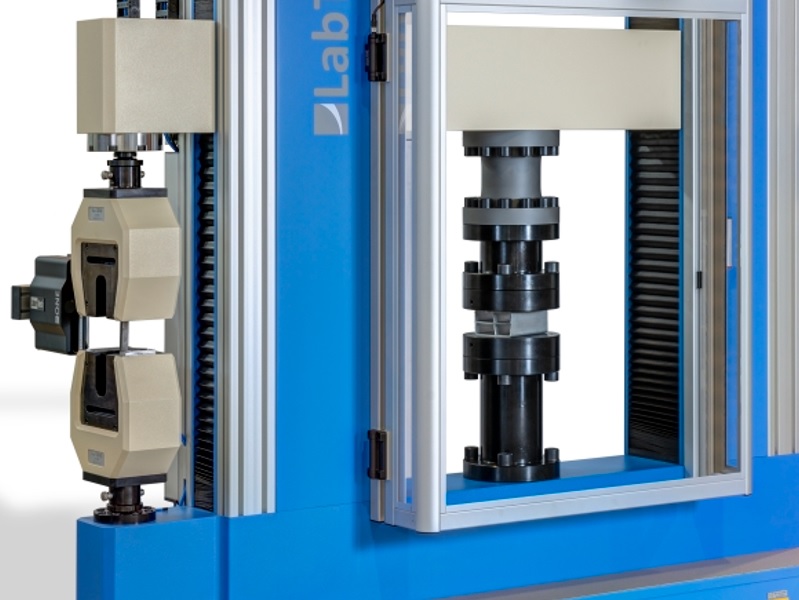

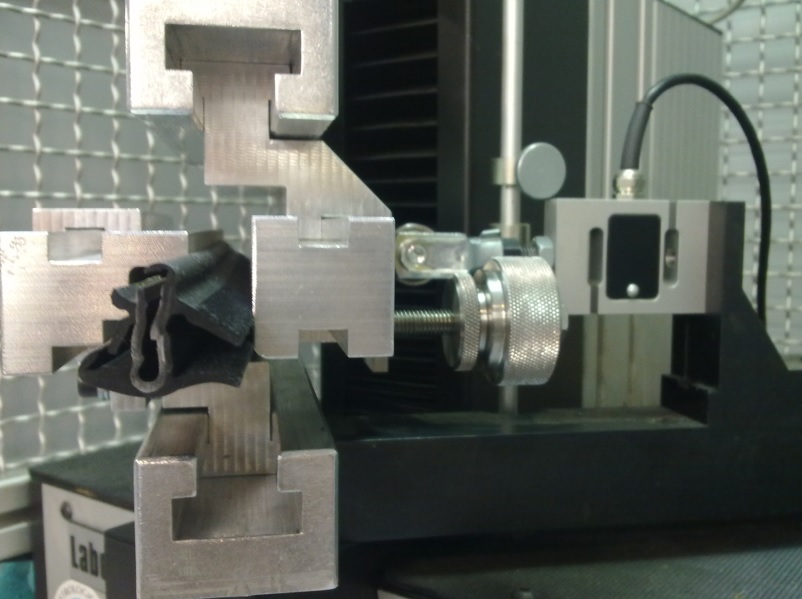

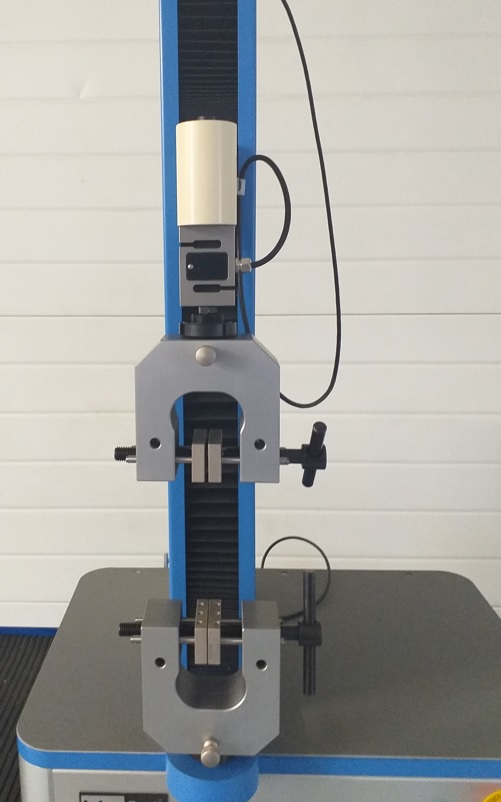

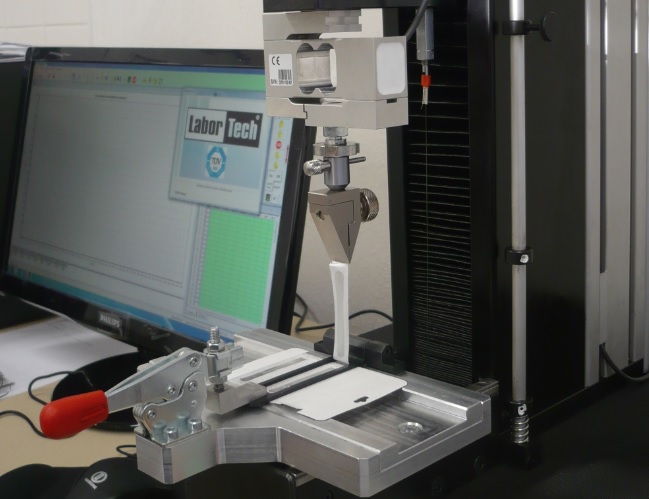

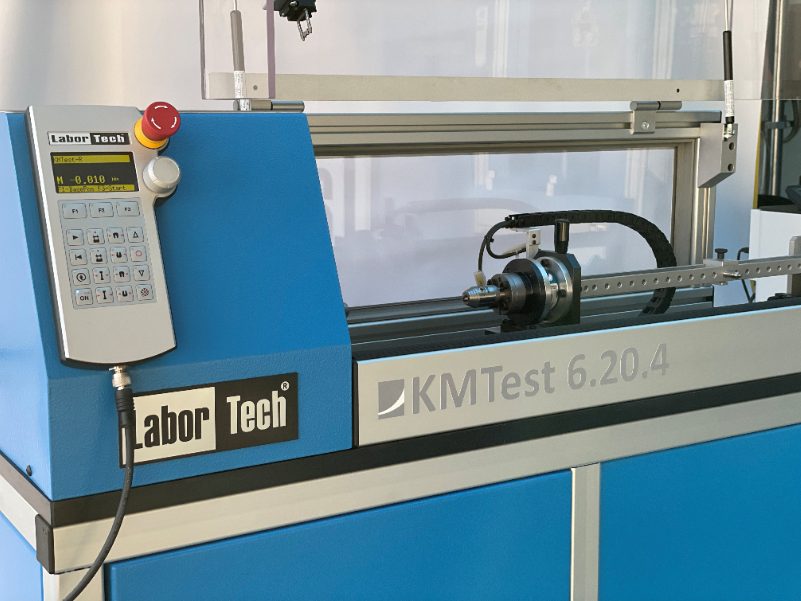

Our force transducers with mounting thread or flange are designed for highly accurate measurement of tensile and compressive forces in the range from 1 N to 10 MN. Thanks to their robust design, high fatigue resistance and long-term stability, they are the ideal choice for static, cyclic and fatigue tests in demanding industrial environments.

They are mainly used in testing machines for testing materials, parts and structures – from laboratory applications to heavy industry

Wide measuring spectrum – S series sensors: 1 N – 100 kN, threaded version: 10 N – 5 MN, flanged version: 500 N – 10 MN

High fatigue resistance: Load capacity limit > 100 million load cycles

Integrated EEPROM with calibration data separately for tension and compression, including linear compensation for maximum accuracy

Suitable for a wide range of tests: Tension and compression tests, static, cyclic and fatigue tests with variable loads

Full compliance with international standards: ČSN EN ISO 7500-1 (accuracy class up to 0.03), ČSN EN ISO 376 (calibration of force gauges), ASTM E4 – Standard Test Methods for Force Verification of Testing Machines, ASTM E74 – Calibration of Force-Measuring Instruments for Verifying the Force Indication of Testing Machines

MEZERA

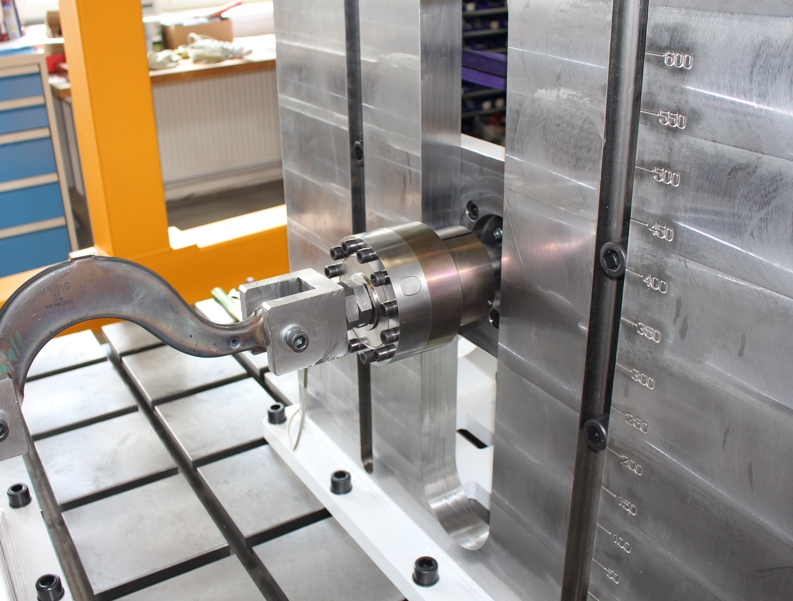

Torque transducers for static and rotational torsion tests

Torque under supervision – reliably, repeatably, with the highest precision…

Accurate torque measurement for static and dynamic applications

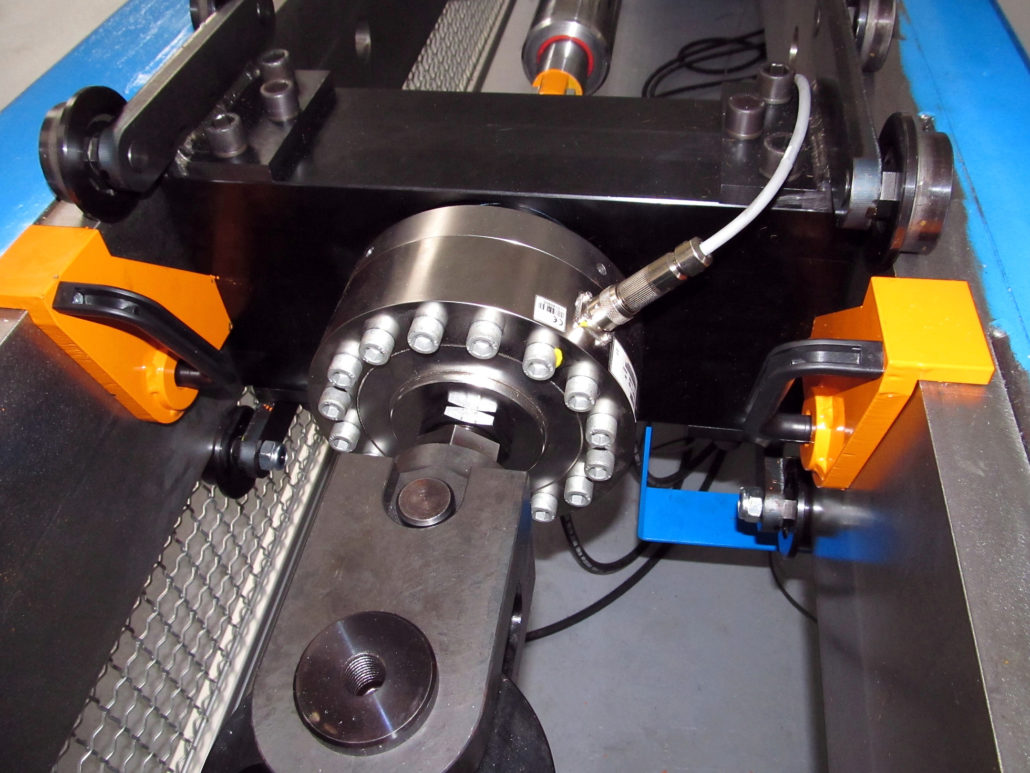

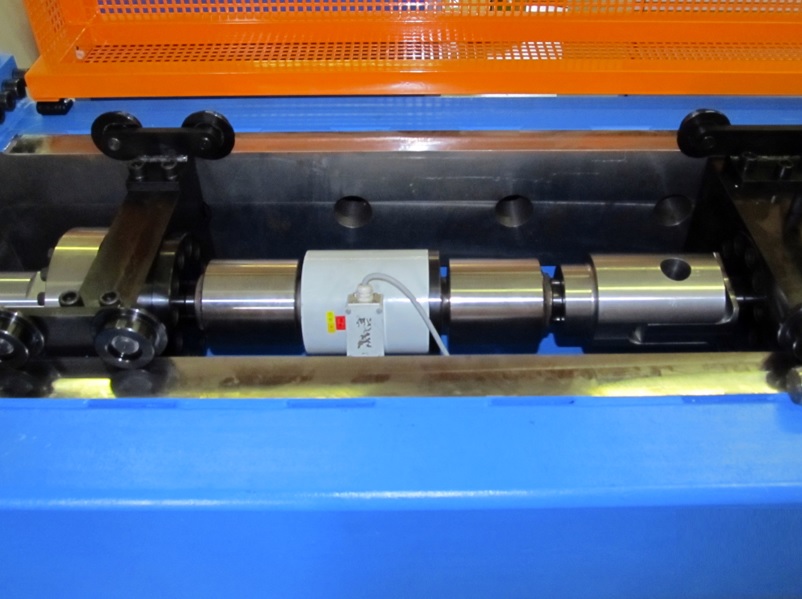

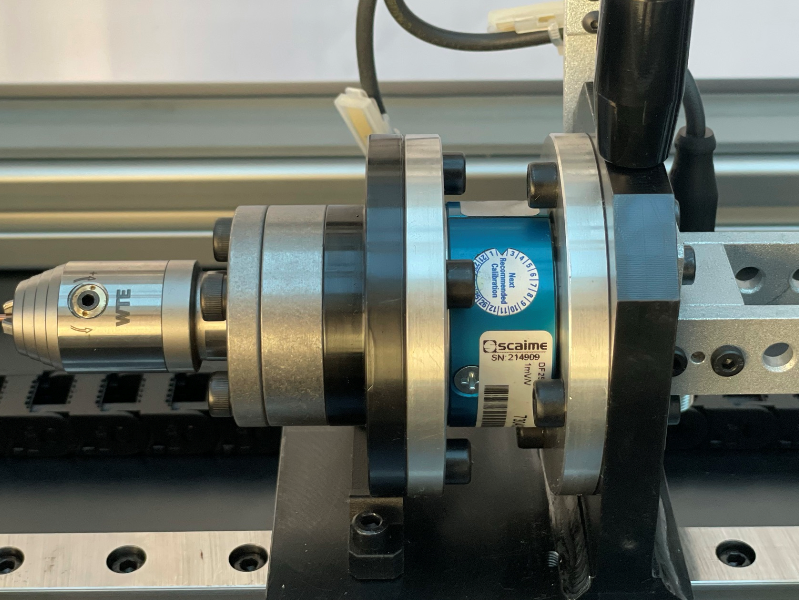

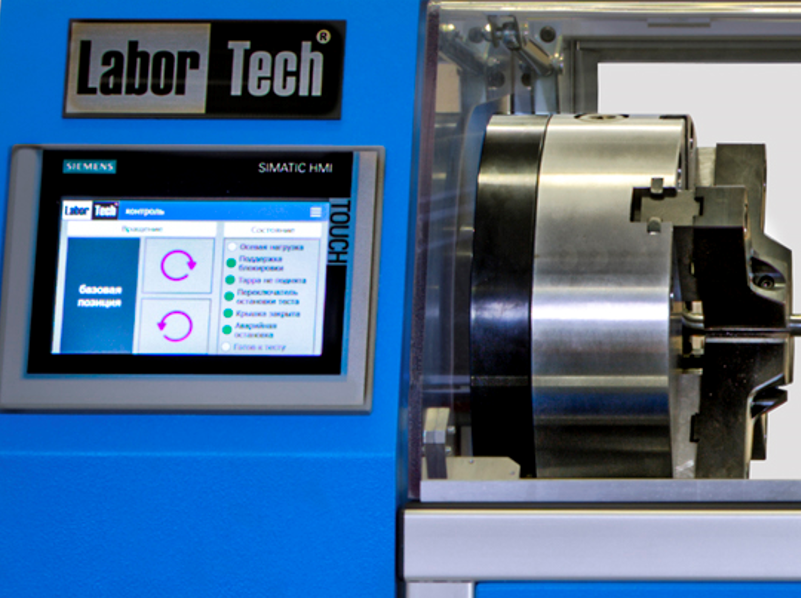

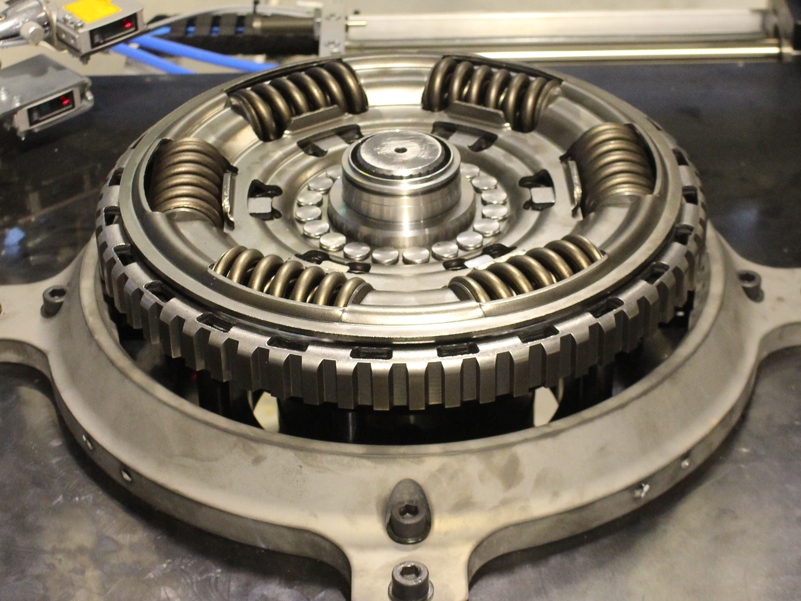

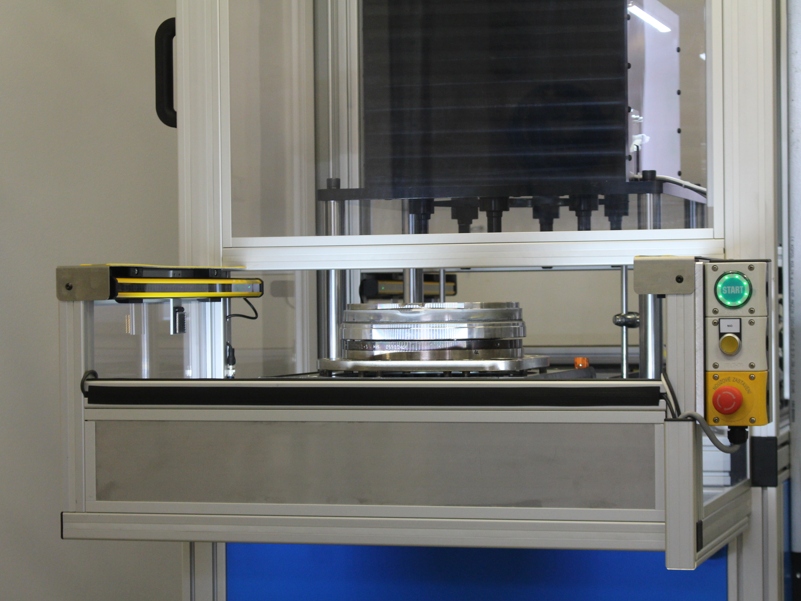

Torsion (torque) sensors are used for highly accurate torque measurement in a wide range of technical and industrial applications. They are mainly used in test benches, test systems, development laboratories and in production processes, where maximum control and reliability of measured data is required.

The sensors are available in static and dynamic versions, both in rotary and non-rotary versions. They are equipped with an integrated EEPROM memory with stored calibration constants separately for both measurement directions (right and left torque), including linear compensation to increase accuracy. They allow short-term overloading of up to 150% of the nominal value, which guarantees safe operation even in the most demanding conditions.

We supply two basic types of sensors according to the method of use:

Rotary torsion sensors with a measuring range from 0.5 Nm to 500 Nm, designed for measuring torque on rotating parts – for example, on engine shafts, transmission systems or clutches.

Flange-mounted torque sensors with a range from 2 Nm to 150 kNm, ideal for fixed mounting in static or dynamic applications with high loads.

LABORTECH torque sensors are designed to meet the most stringent requirements for measurement accuracy and repeatability, in accordance with international standards such as ČSN, EN, ISO or ASTM.

MEZERA

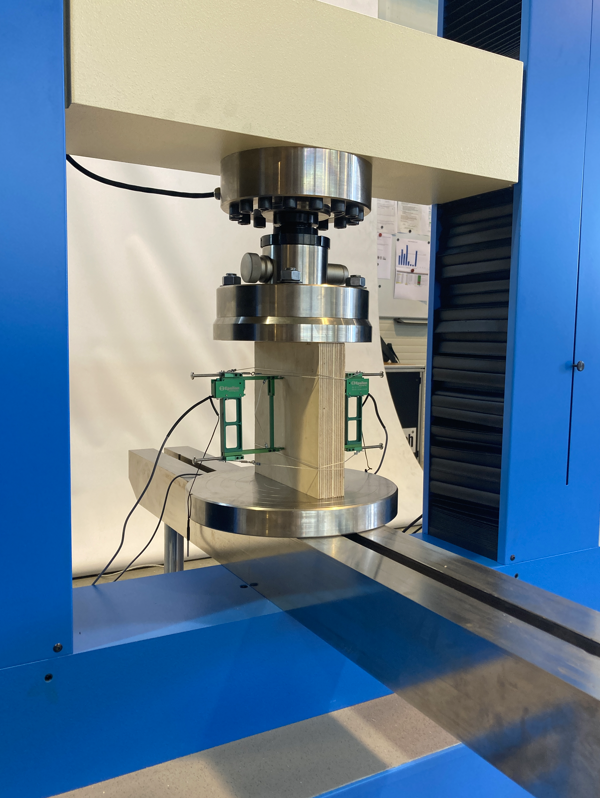

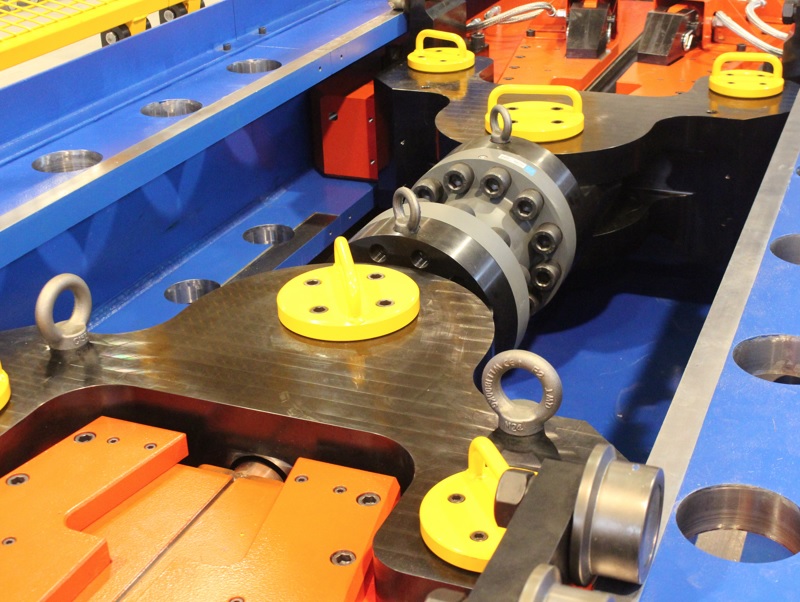

Combined axial-torsion sensors for static and rotational torsion tests

Combined sensors that withstand more than just torque – accuracy, reliability and performance for every application…

Combined axial-torsional sensors – multi-axis accuracy

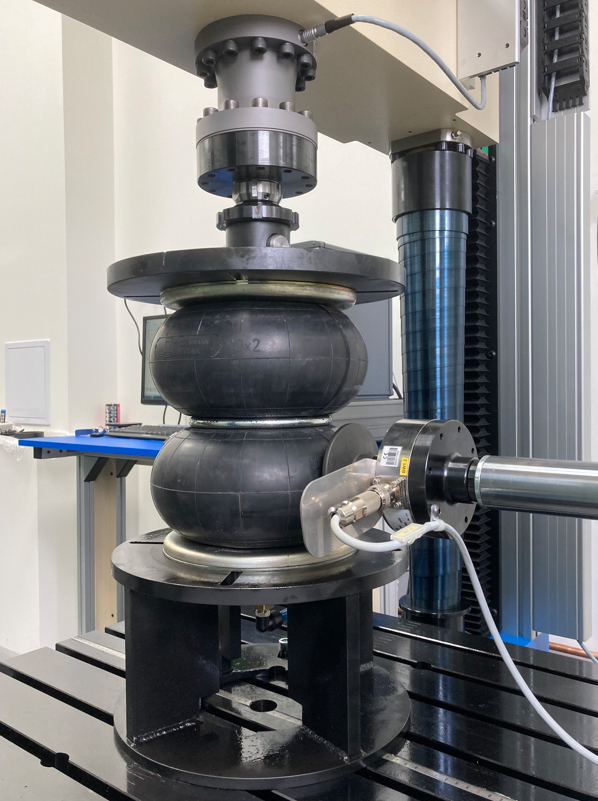

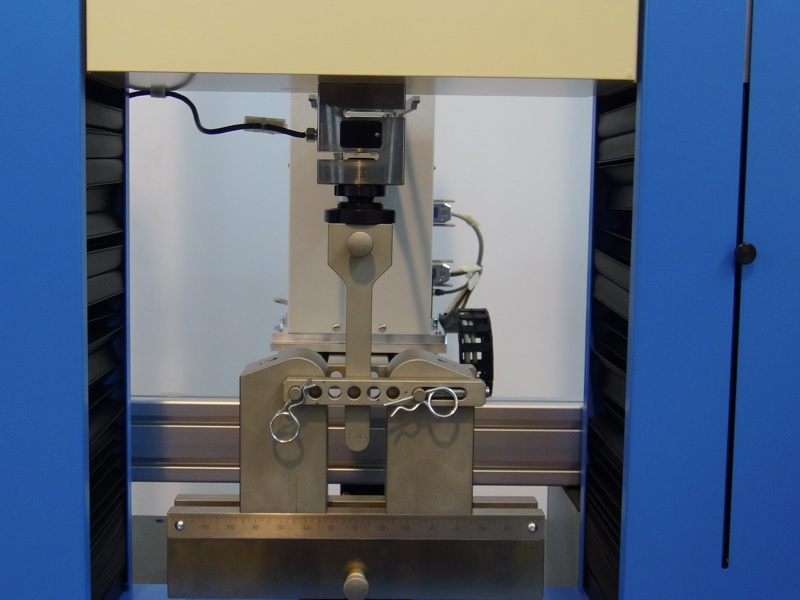

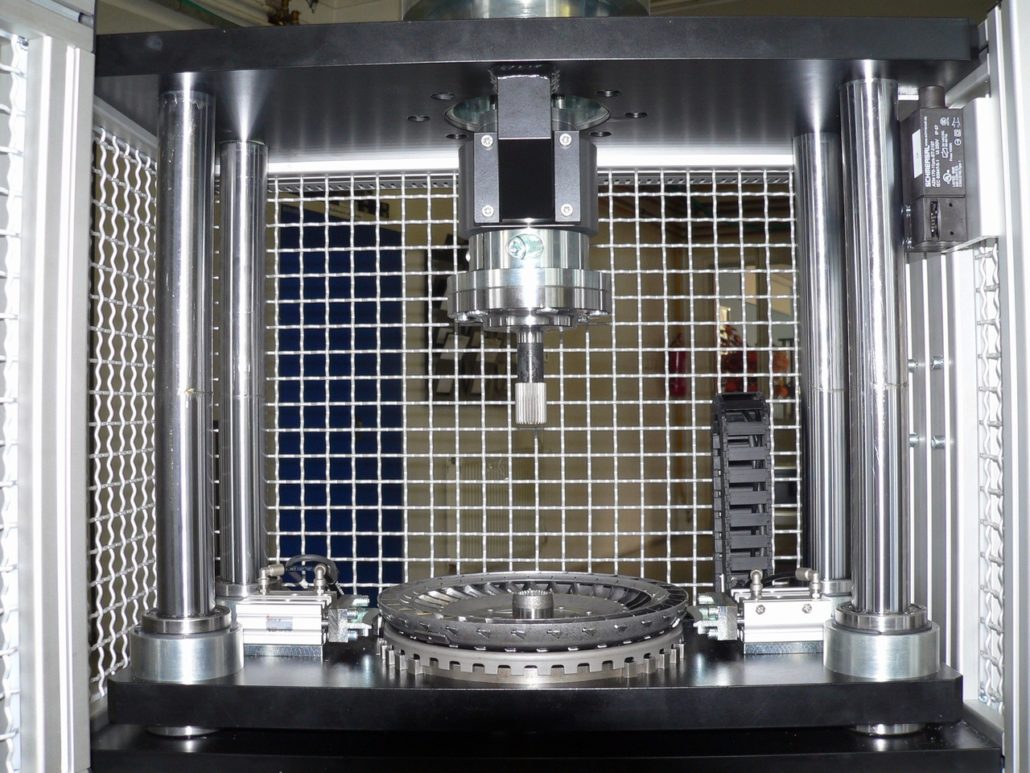

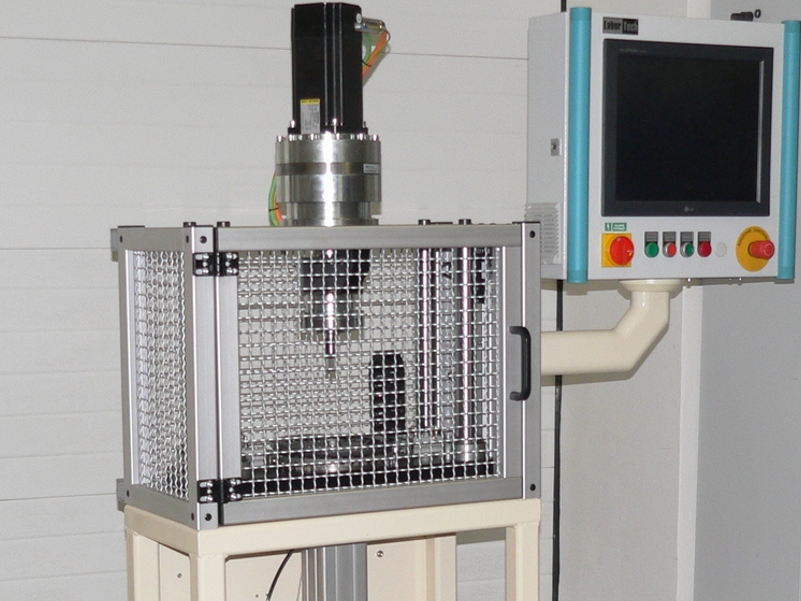

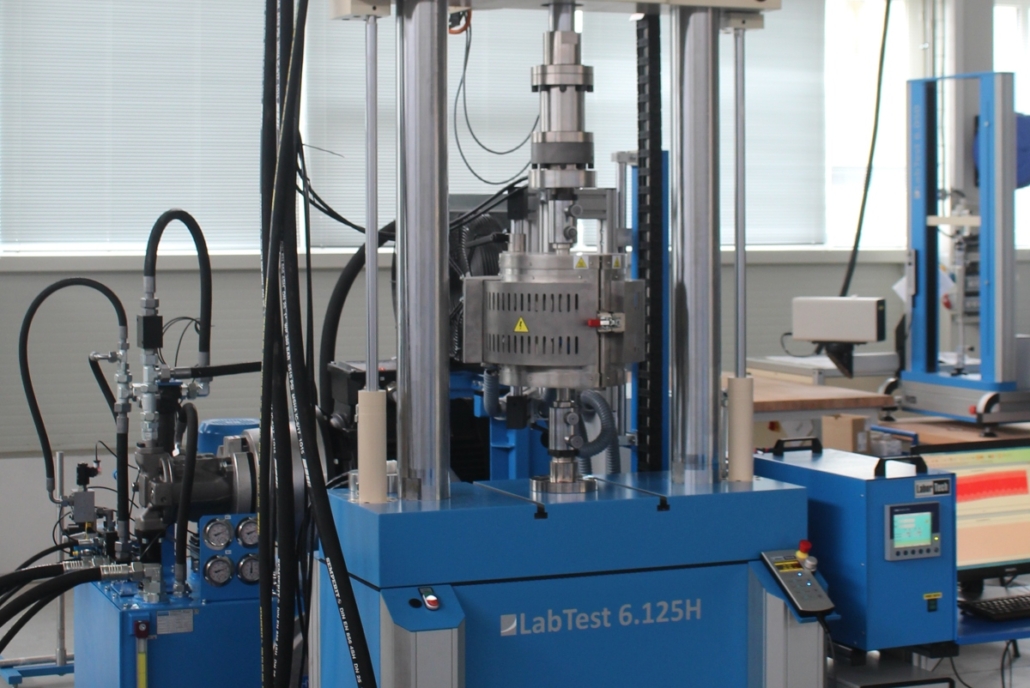

The combination of a force and a torsion sensor creates a multi-axis measuring system that is the ideal solution for demanding axial-torsional tests. These sensors are designed specifically for use in LABORTECH axial-torsional testing machines, where they enable simultaneous and synchronous measurement of axial forces and torque.

Systems equipped with these sensors can handle both tensile and compressive loads, as well as torsional loads or complex combinations of both modes, which is necessary when testing fasteners, material samples and complete assemblies exposed to multiple loads.

To ensure maximum accuracy and reliability, the sensor is equipped with an integrated dual EEPROM memory with stored calibration constants separately for:

tension / compression (axial forces) and bidirectional torque (right / left direction). Linear compensation is also included, which ensures high fidelity of results even under dynamic loading.

Combination ranges: Force sensor: from 200 N to 2000 kN and Torsion sensor: from 2 Nm to 10 kNm

These multi-axis sensors provide a compact, robust and accurate solution for modern test equipment where multiple load components are required to be measured simultaneously – without compromising on accuracy or stability.

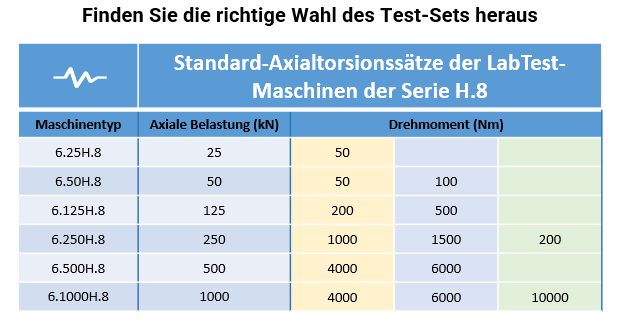

Standard assemblies:

MEZERA

Contact

LABORTECH s.r.o. , Rolnická 1534/130a, 747 05 Opava, Czech Republic

Research & Development

Reducing energy intensity We increase your productivity Development and implementation

News & Events