Automatic hardness tester BRFest 250E-ATB-D5R for testing pressure cylinders

Our company LABORTECH has successfully completed the installation of the automatic hardness tester BRFest 250E-ATB-D5R, which is designed for testing the hardness of pressure cylinders according to the standards ČSN EN ISO 6506-1, ČSN EN ISO 6506-2 and the relevant international standards ASTM E10 and ASTM E92.

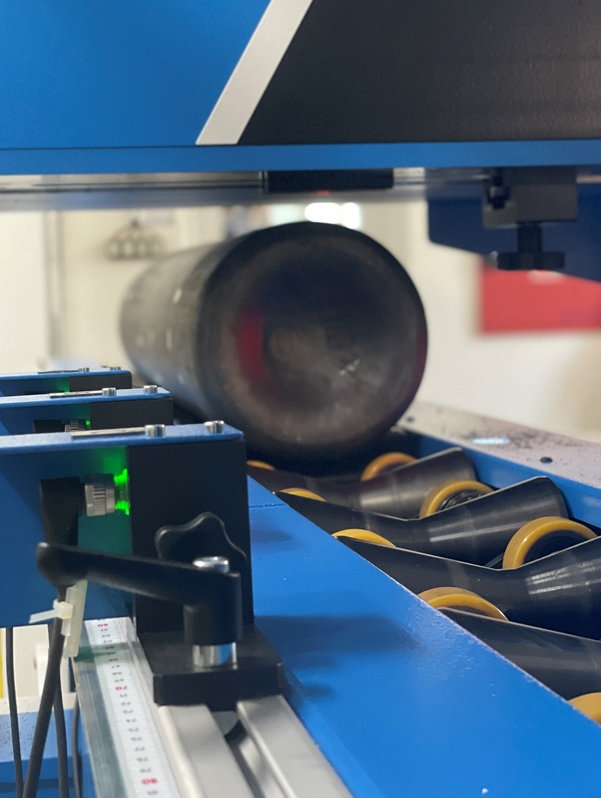

The device allows measurements to be made in the range of 200 to 500 HB, with a test load of 187.5 kg and a ball with a diameter of 2.5 mm. The hardness tester is designed for pressure cylinders weighing up to 150 kg and with a diameter of 100 to 220 mm.

The system includes a rotary cylinder adjustment mechanism that provides hardness measurements at up to 12 points around the circumference (standard setting), with no limit to the number of measuring points on one sample. For handling heavy samples, the X-SLOB conveyor system from our portfolio is used, which ensures precise and safe handling.

The hardness tester is controlled via a modern LCD touch panel and modified FESTTest software, which offers an intuitive user interface, extended settings and test evaluation options.

Thanks to the combination of robust mechanical design, smart automation and a user-friendly environment, this hardness tester delivers higher accuracy, speed and safety in testing.

This project is further proof that LABORTECH is a technological leader in the field of testing technology, offering its customers reliable, efficient and innovative solutions tailored to their needs.

TEAM LABORTECH

Leave a Reply

Want to join the discussion?Feel free to contribute!