Contact

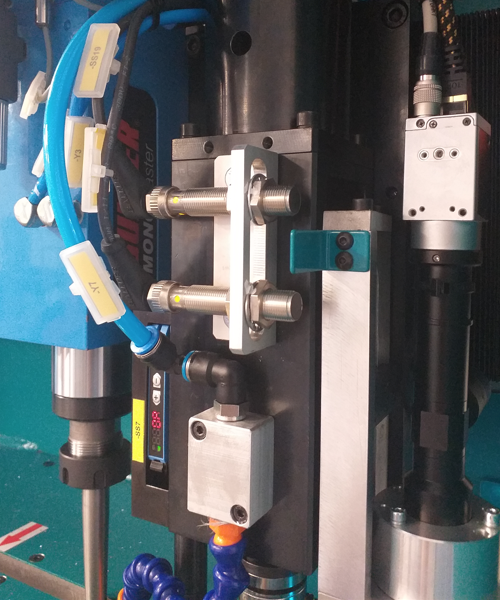

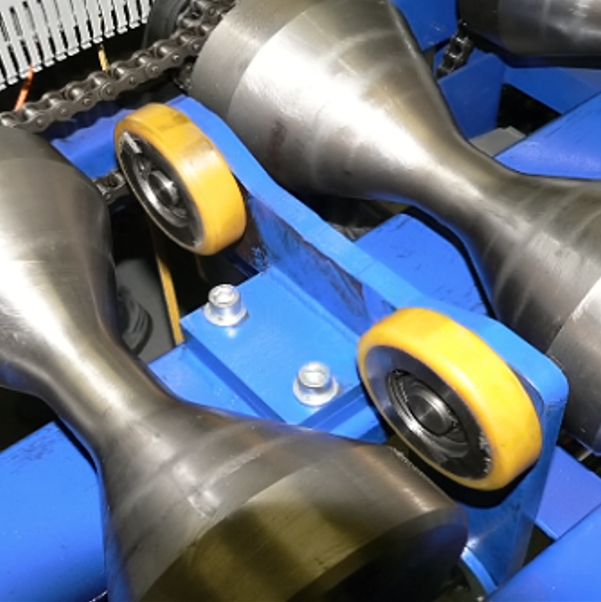

BRFEST-ATB systems are single-purpose, fully automated devices developed exactly according to customer requirements. This line of machines is intended exclusively for testing parts in automatic mode, using the X-SLOB or X-RUNNER handling and loading systems, which ensure fast, safe and reliable sample handling.

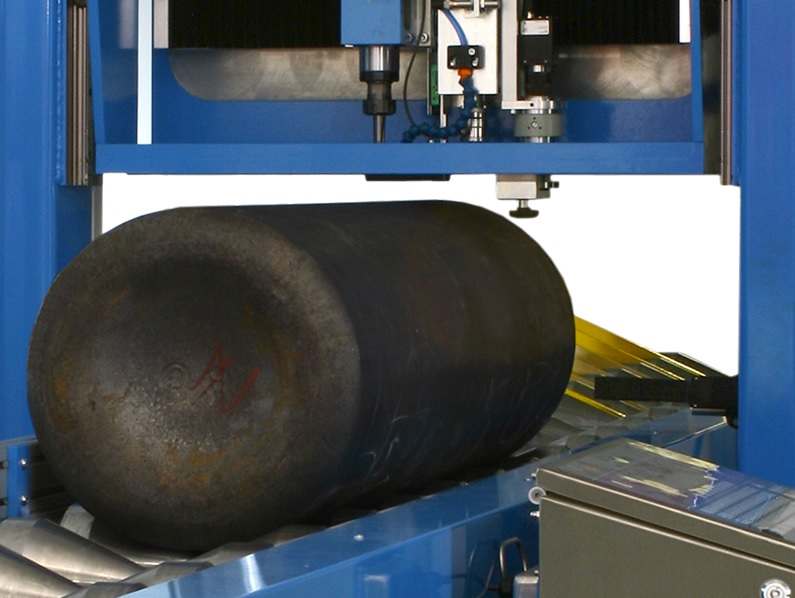

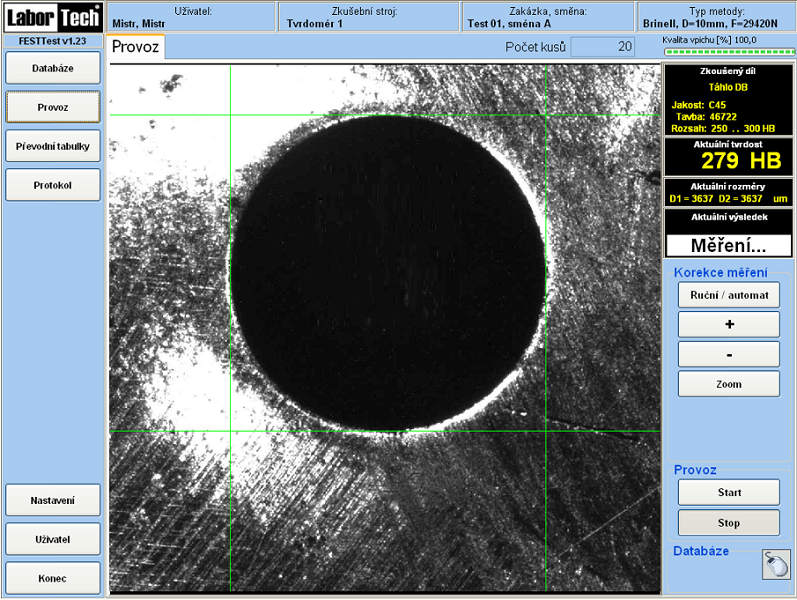

Part of the hardness measurement is the preparation of a control surface for performing the puncture, the size of which is always decided according to the customer’s specifications. The results are evaluated using modern FESTTest software, which provides accurate and reproducible hardness values in accordance with international standards.

The safety of the entire system is controlled by an industrial SIEMENS PLC, which constantly monitors the operation of the device and ensures the protection of the operator and the tested samples. Thanks to its reliability, accuracy and ease of operation, the BRFEST-ATB system represents an effective solution for fully automated hardness testing in industrial operations and laboratory practice.

BRFEST 250E – ATB system – automatic hardness measurement, the Brinell method-EDITION 30

Description:

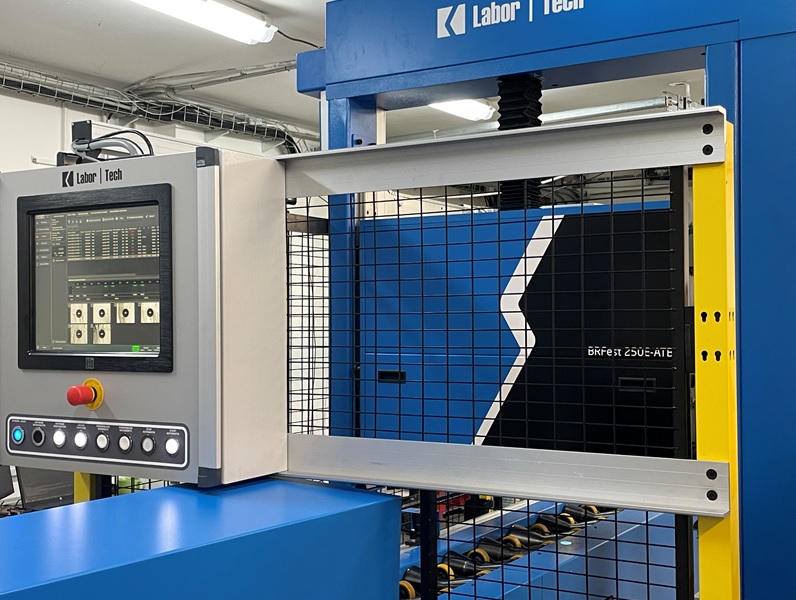

The BRFEST-ATB automatic hardness testing systems from LABORTECH are INNOVATED, single-purpose and fully automated devices developed exactly according to customer requirements. They are produced in several modifications according to the selected Brinell method, the number of samples tested within 24 hours, the type of parts, the number of punctures and the required cycle. Thanks to these parameters, each workplace is precisely specified for a given purpose. The new generation of BRFEST-ATB is equipped with the latest technologies and FESTTest 5.6 software, which offers intuitive control and maximum accuracy of results. The machine is controlled via a 17″ touch LCD panel with integrated PC, located in an industrial cabinet with air conditioning for long-term stability and reliability.

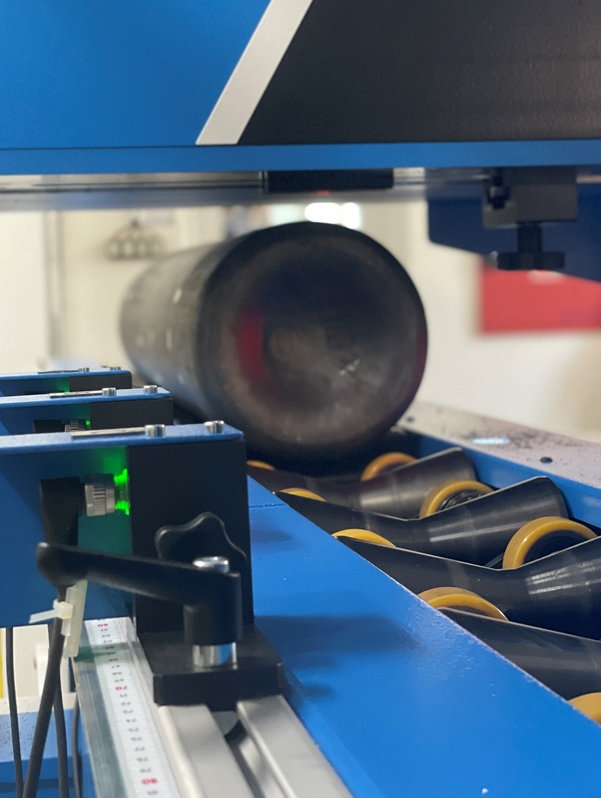

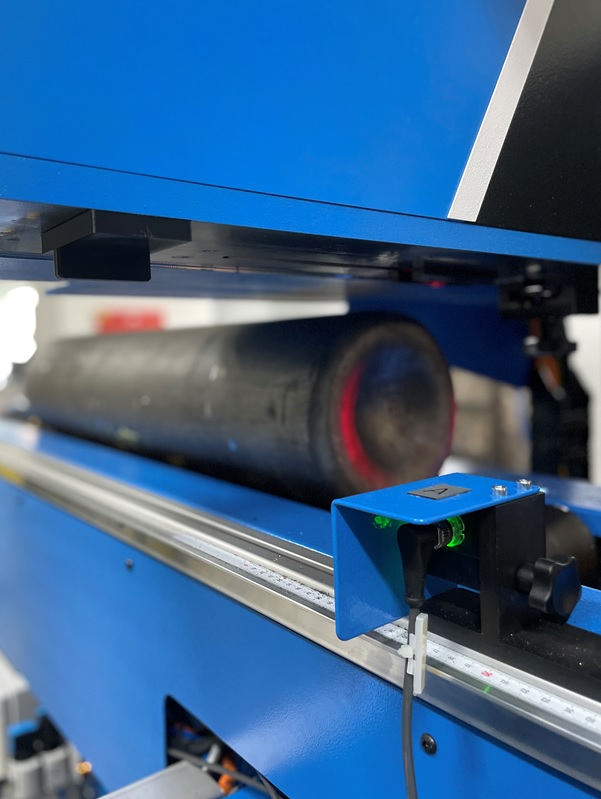

For automatic testing of parts, the systems are supplemented with X-SLOB or X-RUNNER technologies, which ensure fast and safe handling of samples. The measurement also includes automatic preparation of the puncture area according to customer specifications. The safe operation of the system is monitored by an industrial SIEMENS PLC. BRFEST-ATB thus represents an effective solution for fully automated hardness testing in industrial and laboratory environments, with an emphasis on productivity, accuracy and long-term reliability.

Characteristic features:

Modular and economical system with the possibility of customization according to customer requirements.

Automatic evaluation of the puncture including saving to the database.

Low operating and maintenance costs including 100% machine utilization (3-shift operation).

Simple sample loading under the puncture and evaluation device.

SIEMENS Simatic S7 1500 control system incl. FESTTest software

Use – Standards:

ČSN EN ISO 6506-1 nebo ČSN EN ISO 6506-2, 6507-2, 6508-2, ASTM E10 a ASTM E92.

Expandable accessories:

Various types of conveyor systems depending on the type of samples, marking and identification devices, instrumentation, X-Y automatic tables for serial testing, robotic sample loading, etc.

BRFEST 250 – ATB system – automatic hardness measurement using the Brinell method

Description:

Automatic ATB hardness measuring system. These systems are manufactured in several modifications depending on: what method will be used to measure Brinell, how many samples will be tested within 24 hours, what types of samples, how many punctures will be made on a given sample, what will be the cycle time, etc. Based on these requirements, the given workplace for hardness measurement is precisely specified. The machine is controlled via a 17″ touch LCD panel with an integrated PC, which is located in an industrial cabinet with air conditioning. Each ATB system includes sophisticated FESTTest testing software.

The safety of the entire system is ensured by an industrial SIEMENS PLC, which constantly monitors the operation of the device and protects both the operator and the tested samples. Thanks to its reliability, accuracy and ease of use, the BRFEST-ATB system represents an effective solution for fully automated hardness testing in industrial environments and laboratories. ezpečnost celého systému zajišťuje průmyslové PLC SIEMENS, které neustále monitoruje chod zařízení a chrání jak obsluhu, tak testované vzorky. Díky své spolehlivosti, přesnosti a snadjjjjjjjjtak testované vzorky. Díky své spolehlivosti, přesnosti a snadjjjjjjjjjjjjjjjjjjjjé ob

Characteristic features:

Modular and economical system with the possibility of customization according to customer requirements.

Automatic evaluation of the puncture including saving to the database.

Low operating and maintenance costs including 100% machine utilization (3-shift operation).

Simple sample loading under the puncture and evaluation device.

SIEMENS Simatic S7 1500 control system incl. FESTTest software

Use – Standards:

ČSN EN ISO 6506-1 nebo ČSN EN ISO 6506-2, 6507-2, 6508-2, ASTM E10 a ASTM E92.

Expandable accessories:

Various types of conveyor systems depending on the type of samples, marking and identification devices, instrumentation, X-Y automatic tables for serial testing, robotic sample loading, etc.

Contact

LABORTECH s.r.o. , Rolnická 1534/130a, 747 05 Opava, Czech Republic

Research & Development

Reducing energy intensity We increase your productivity Development and implementation

News & Events