POSITIONING MANIPULATORS X-SPRINTER

X-SPRINTER positioning manipulators from LABORTECH allow handling of standard standardized samples as well as entire products with standard test systems. The modular system of positioning manipulators offers the possibility to perform the required tests quickly, efficiently and reproducibly. Custom solutions can be individually assembled from standardized components.

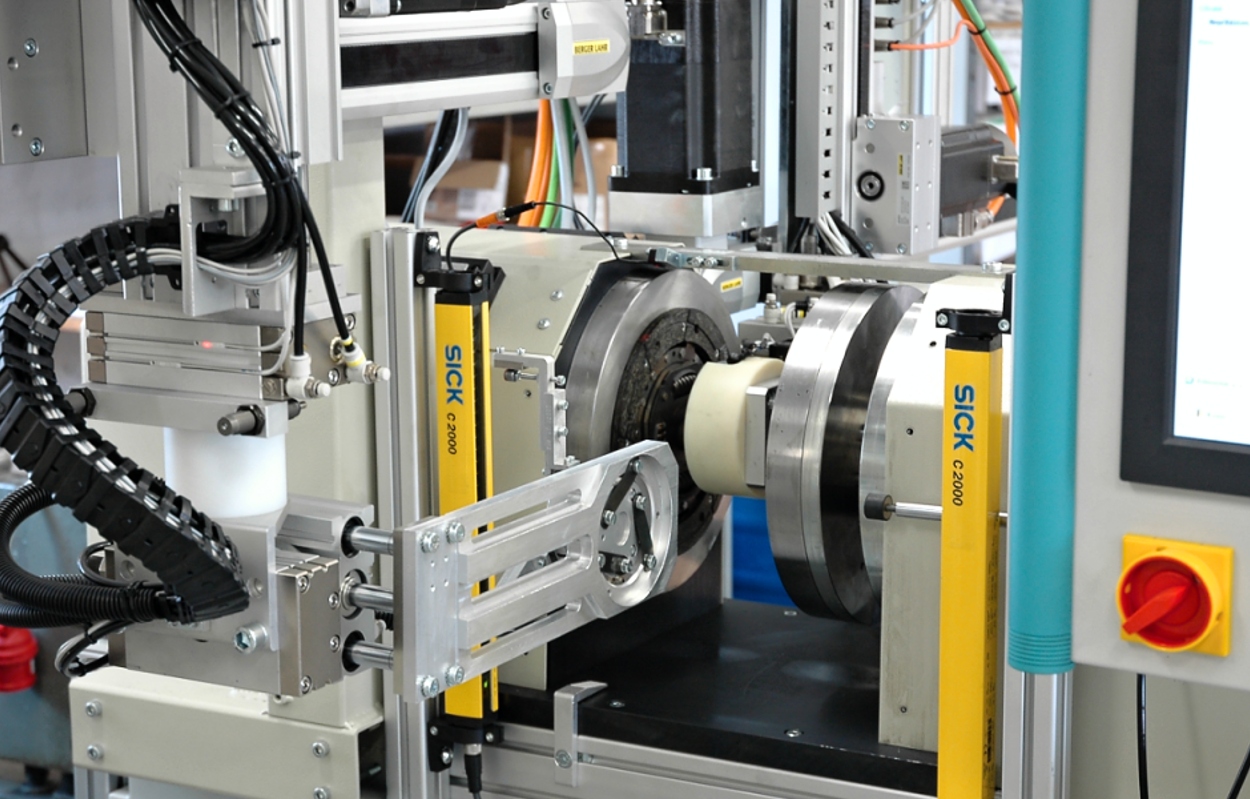

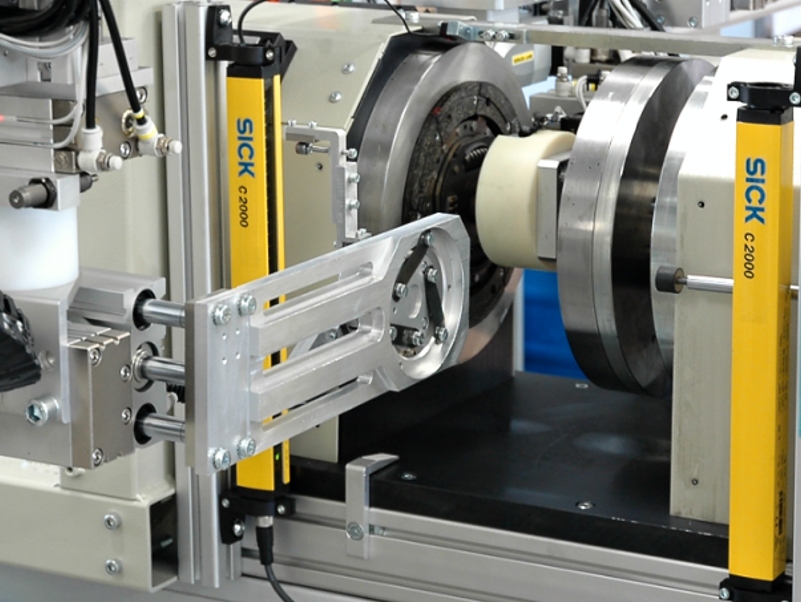

AZS.5 – POSITIONING MANIPULATORS FOR TESTING LAMELLAS

Description:

Double positioning manipulator X-SPRINTER designed for loading and unloading lamellas from the ABCControl lamella inspection machine with automatic selection of NIO parts according to the given error. The line consists of several separate parts. LABORTECH ensures the functionality of the entire line.

Characteristics:

Handling of the lamellas is ensured by SCHNEIDER positioning manipulators. automatedautomatedautomatedautomatedautomatedautomateda

Identification and history of parts through optical inspection ensuring correct riveting of the lamella.

X RUNNER controller in conjunction with positioning manipulators – SIEMENS Simatic S7 1500 incl. LCD

Total Taktzeit line at the input – 12sec

Application – Standards:

AUTOMOTIVE – testing of automotive lamellas – measurement of mechanical properties of the lamella – system of measurement and evaluation according to ZF standards.

Expandable accessories:

Different types of trays depending on the type of samples, optical inspection equipment for correct lamella riveting, MARKRATOR marking and identification equipment, special clamping grippers, boxes for identification of IO and NIO parts, conveyor systems, extended storage systems, etc.

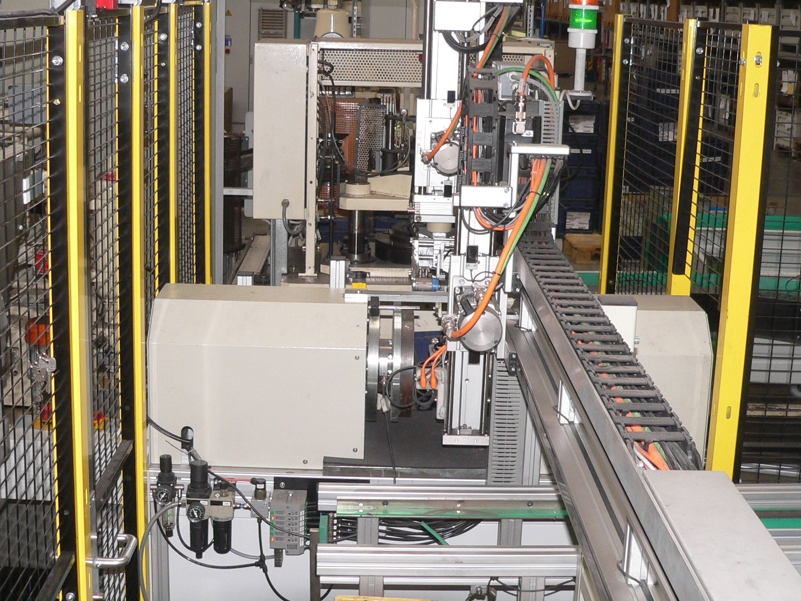

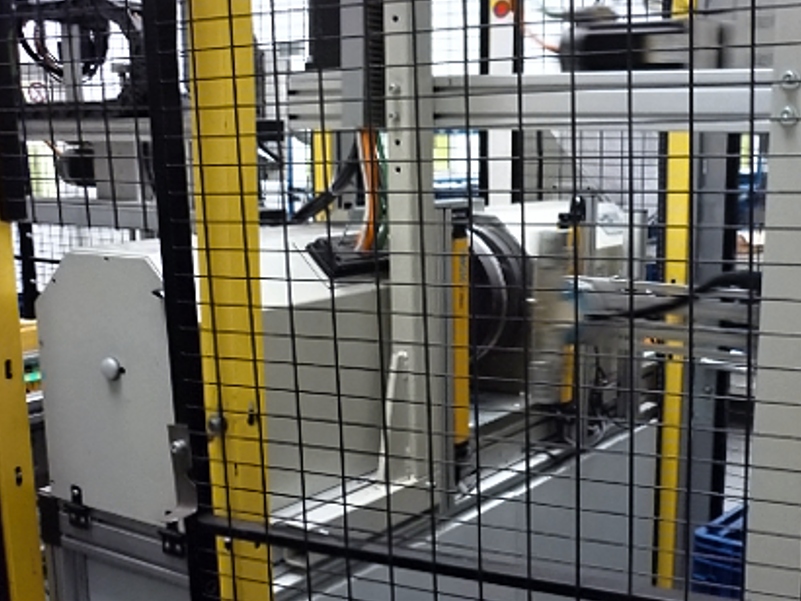

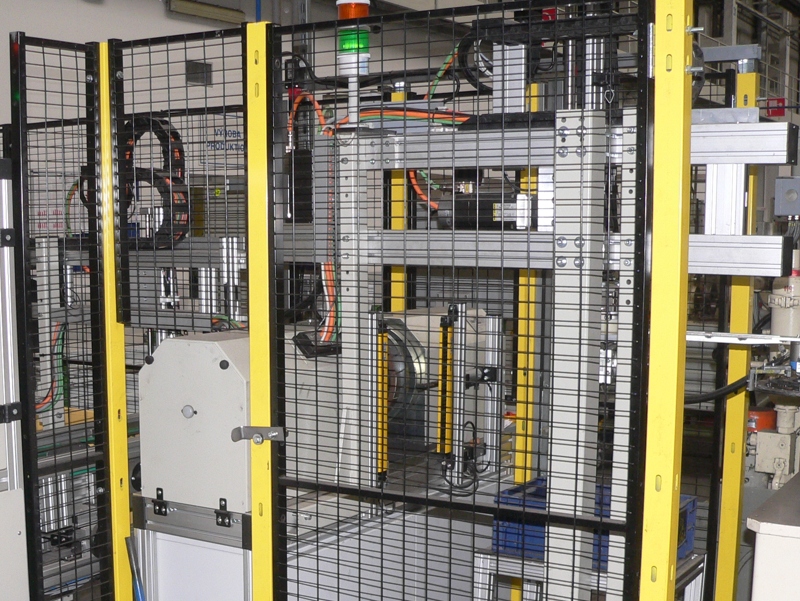

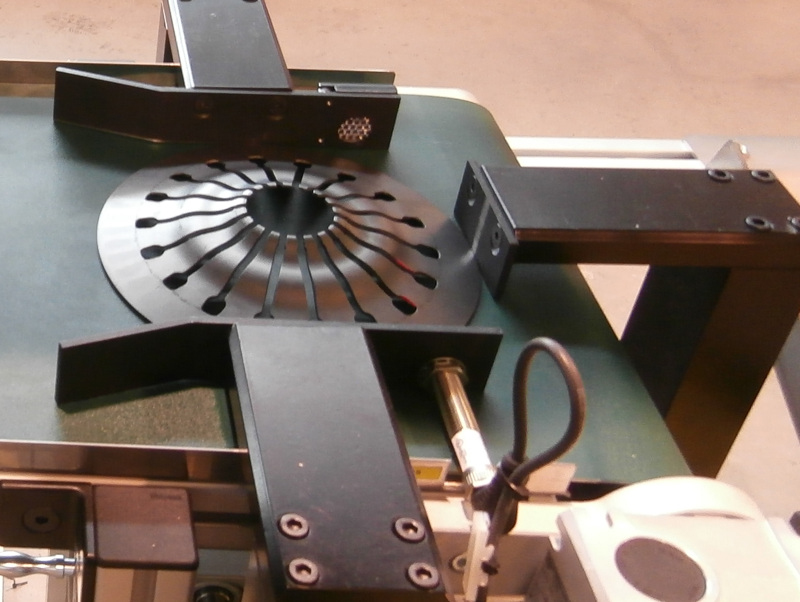

AZS.6 – POSITIONING MANIPULATORS FOR SPRING TESTING

Description:

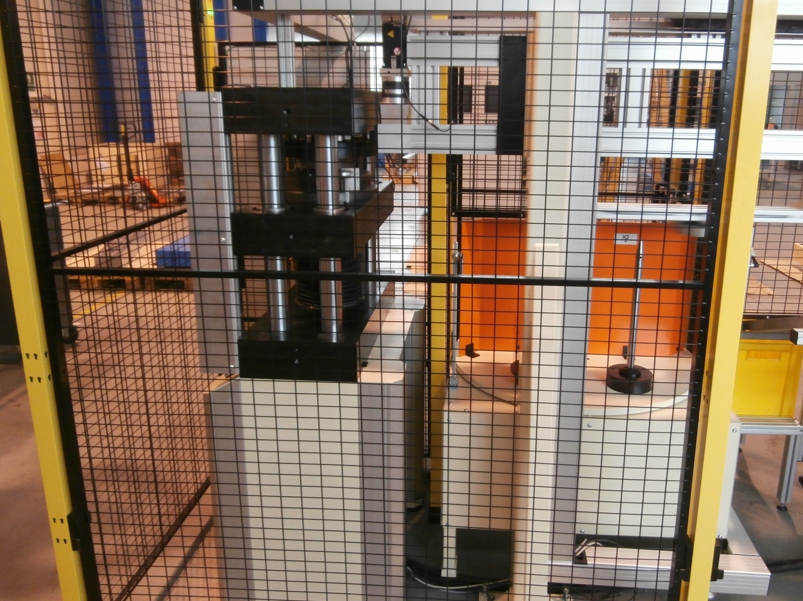

Complex automated line designed for heat treatment of PKW spring including 100% mechanical spring control with automatic correction according to a special dynamic algorithm. The line consists of several separate parts. The guarantor and creator of the line was LABORTECH. automatedautomatedautomated

Characteristics:

Complete line with induction hardening and sandblasting system, camera optical inspection of the spring, mechanical inspection of the spring …

Handling of the slats is ensured by positioning manipulators SCHNEIDER and FESTO.

X RUNNER controller in conjunction with positioning manipulators – SIEMENS Simatic S7 1500 incl. LCD

Total Taktzeit at the input – 13 sec

Application – Standards:

AUTOMOTIVE – testing – measurement of mechanical properties of the spring – system of measurement and evaluation according to ZF standards.

Expandable accessories:

Different types of containers depending on the type of samples, optical inspection equipment for the correctness of turbidity, marking and identification equipment, special handling grippers, boxes for identification of IO and NIO parts, conveyor systems, extended storage systems, etc.