Notching device VRE for creating U and V notches

MEZERA

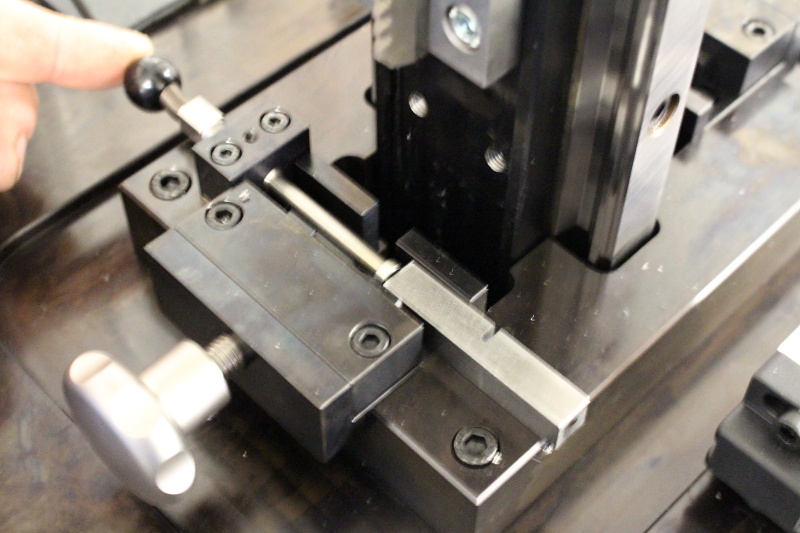

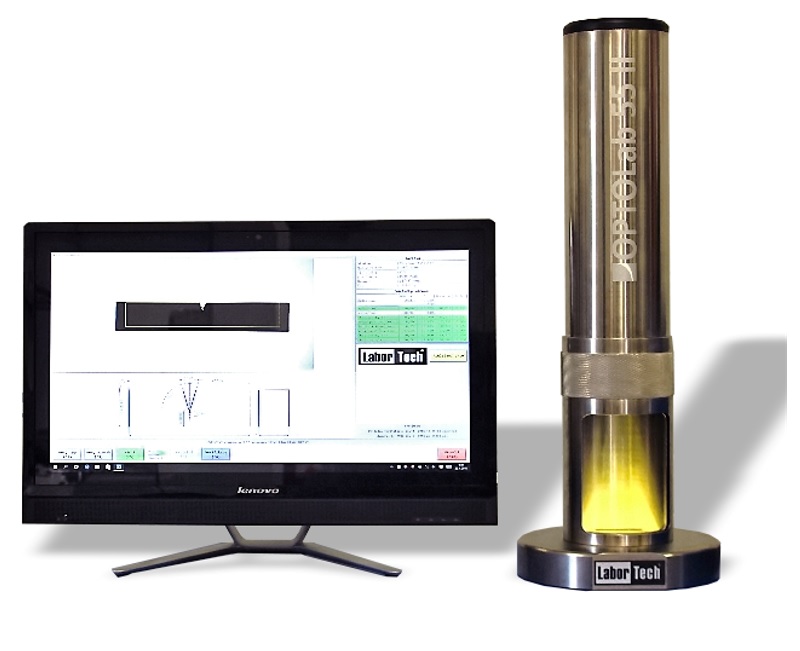

The VRE device is intended for the creation of V and U notches in samples intended for notch toughness tests according to the standards EN ISO 148-1, ASTM E23, GOST 9454, EN ISO 179. The device was designed so that in conjunction with optical inspection of samples OPTOLab 55 II forms a comprehensive workplace that provides 100% of the sample for notched toughness.

Download:

MEZERA

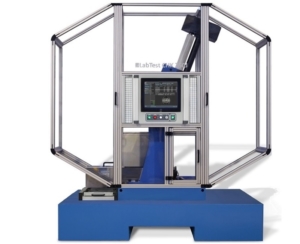

Key features of the VRE 20 system series

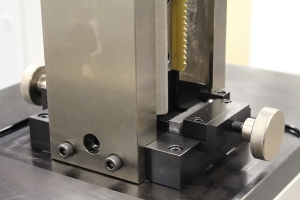

- Robust and very rigid stand construction with high stability when notching

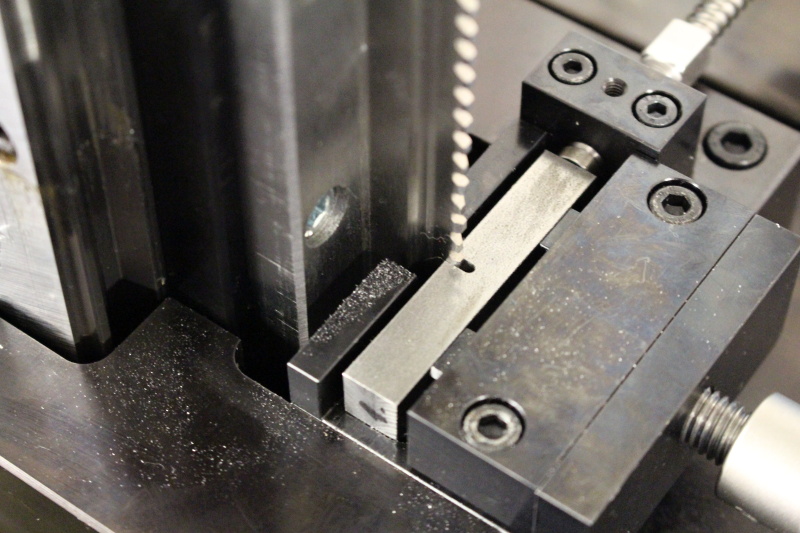

- Notch formation in accordance with EN ISO 148-1, GOST 9457-78, ASTM E 23 standards

- Possibility to make two different notches at once.

- Easy blade change for V2, U2, U3, U5 and subsequent adjustment

- Very high notch milling speed with automatic cycle

- Continuous speed control can be used to mill a V or U groove on the machine into any material not exceeding the hardness of 40HRC.

- Thanks to an ingenious system, the milled chips are caught in the lower part of the machine, where they can be easily and safely removed.

- Centrally located controls for easy machine operation.

- VRE system with protective safety cover, corresponding to EC directives on machinery working in accordance with new safety functions according to EN ISO 13850-SIL 1 / PL.

- Integration into the X RUNNER robotic system.

MEZERA

VIDEO of VRE 20 device

Production of U and V notches for notched toughness samples

Výroba U a V vrubů u vzorků vrubové houževnatosti přesně, rychle a stabilně v souladu s normou EN ISO 148-1, GOST 9457-78, ASTM E 23

Do you have questions about our products?

Feel free to contact our product experts.

We look forward to your interest.

–