CONVEYOR LINE SYSTEMS X-SLOB

Innovative Solution for Material Handling: X-Sprinter Positioning Manipulators

Transferring materials from one point to another in a manufacturing process or laboratory environment can be a key component of efficiency and success. X-Sprinter positioning manipulators represent an innovative solution that utilizes the principle of roller tracks for fast and precise transfer of materials or test samples from point A to point B. This technology provides a reliable and simple way to handle materials and ensures efficient workflow processes.

Simple Interface for Effective Manipulation

X-Sprinter positioning manipulators are designed with an emphasis on simplicity and efficiency. Their user-friendly interface allows for easy operation and adjustment, increasing productivity and minimizing the time required for material handling. Thanks to their intuitive design, workers can quickly and reliably perform material transfers without lengthy training or complex procedures.

Roller Track Principle for Smooth Movement

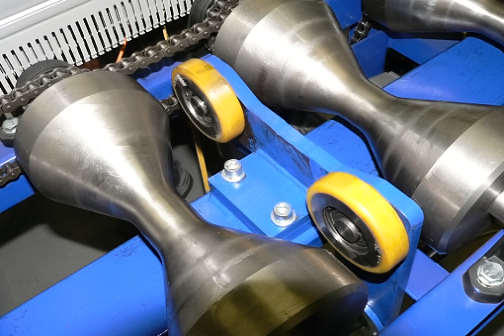

One of the key components of X-Sprinter positioning manipulators is the use of roller tracks. These tracks enable smooth and seamless movement of material or samples between different workstations. This makes material handling easy and trouble-free, increasing efficiency and minimizing the risk of material damage.

Single-Purpose and Mechanical Durability

X-Sprinter positioning manipulators are designed with a focus on single-purpose functionality and reliability. Their robust construction and durable materials ensure long-term durability and minimal maintenance requirements. Consequently, they are an ideal solution for environments where continuous manipulation of materials or samples is required.

Efficient Solution for Industry and Laboratories

X-Sprinter positioning manipulators are a suitable choice for a wide range of industrial sectors and laboratories where precise and reliable material or test sample transfer is needed. Their simplicity, reliability, and high efficiency contribute to optimizing workflow processes and increasing overall productivity and competitiveness of the business.

polohovací manipulátory

AUTOMATIC WORKING STATIONS FOR THE MEASUREMENT OF CNG BOTTLES HARDNESS

Description:

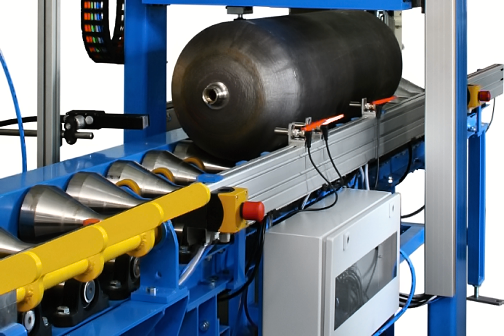

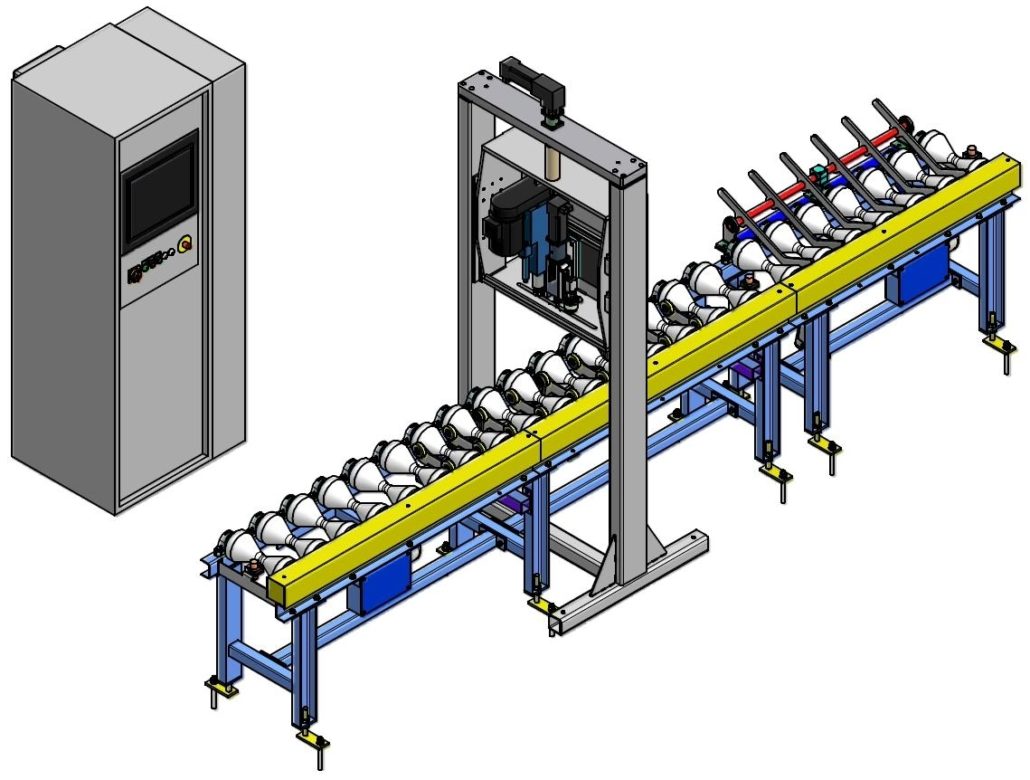

Automatic stationary hardness testers designed for HB and HV measurement. Built-in production and testing lines, they are used for 100% hardness check according to EN ISO 6506-1. These systems can measure e.g. CNG bottles after heat treatment, seamless pipes, round forgings etc. The conveyor system can be adjusted according to the dimensions, shape and weight of the measured piece and requirements.

Features and description::

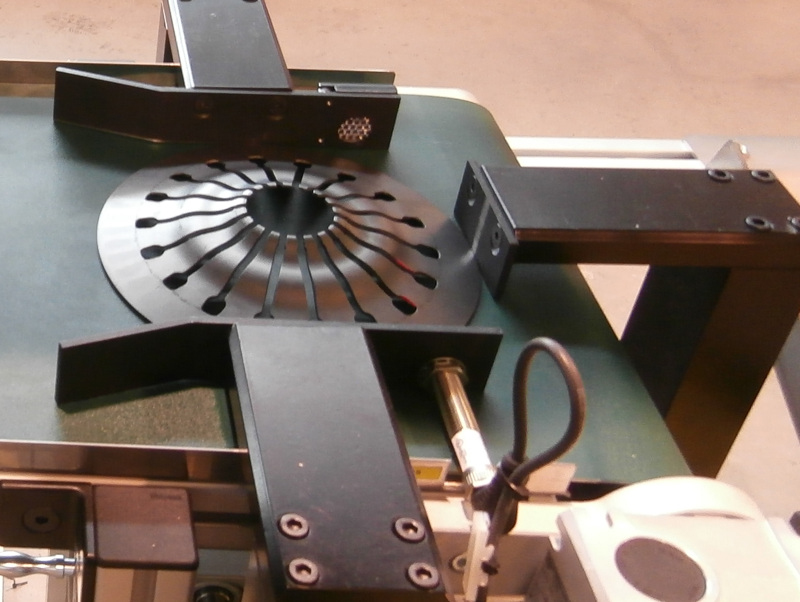

Sturdy frame construction with vertical pressure actuator with linear guide. Horizontal unit with feedback support, milling, injection, and CCD evaluation unit.

Conveyor system for feed and rotation of the piece and selection of parts according to hardness, IO, NIO + and NIO-

Integrated unit of pieces description – IMAJE

Total Taktzeit of input line – 50 secs for one injection (Up to 12 injections in different positions)

SIEMENS Simatic S7 1500 control system incl. LCD, integrated PC incl. FESTTest software

Operation via touch LCD screens

Application – Standards:

According to VITKOVICE CYLINDERS and MILMET standards

Expandable accessories:

Different types of containers depending on the type of samples, optical inspection devices for the correctness of riveting of the lamella, marking and identification devices MARKRATOR, special clamping grippers, boxes for identification of IO and NIO parts, conveyor systems, extended storage systems, etc.

AZS.6 – POLOHOVACÍ MANIPULÁTORY PRO TESTOVÁNÍ PRUŽIN

Popis:

Komplexní automatizovaná linka určená pro tepelné zpracování PKW pružiny včetně 100% mechanické kontroly pružiny s automatickou korekcí dle speciálního dynamického algoritmu. Linka je tvořena několika samostatnými částmi. Garantem a tvůrcem linky byla firma LABORTECH.

Charakteristické vlastnosti:

Kompletní linka s s indukčním kalícím a pískovacím systém, kamerová optická kontrola pružiny, mechanická kontrola pružiny …

Manipulace s lamelami zabezpečena polohovacími manipulátory SCHNEIDER a FESTO.

Ovladač X RUNNER ve spojení s polohovacími manipulátory – SIEMENS Simatic S7 1500 vč. LCD

Celkový Taktzeit na vstupu – 13 sec

Použití – Normy:

AUTOMOTIVE – testování – měření mechanických vlastností pružiny – systém měření a vyhodnocení dle standardů ZF.

Rozšiřitelné příslušenství:

Různé typy zásobníků v závislosti na typu vzorků, optické kontrolní zařízení na správnost zakalení, značící a identifikační zařízení , speciální manipulační chapadla, boxy na identifikaci IO a NIO dílů, dopravníkové systémy, rozšířené zásobníkové systémy atd.